Thermal insulation material and connecting device thereof

A connection device and heat insulation material technology, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of unbalanced vulcanization speed and foaming speed of heat insulation materials, etc., and achieve improvement Anti-ozone cracking, reducing consumption and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

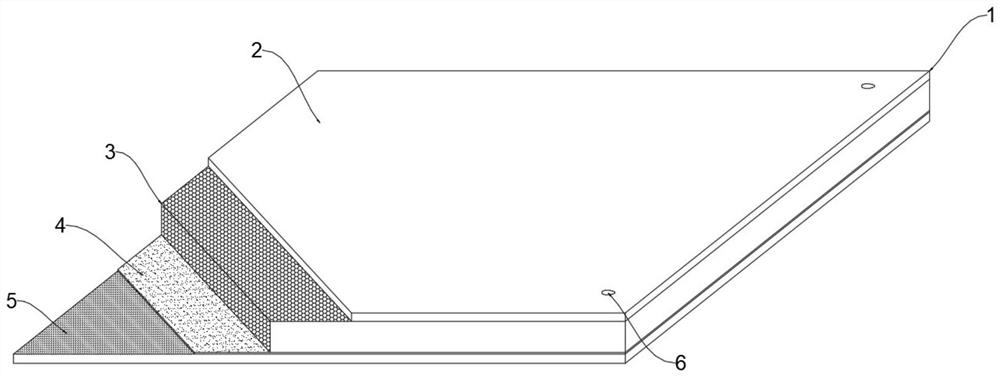

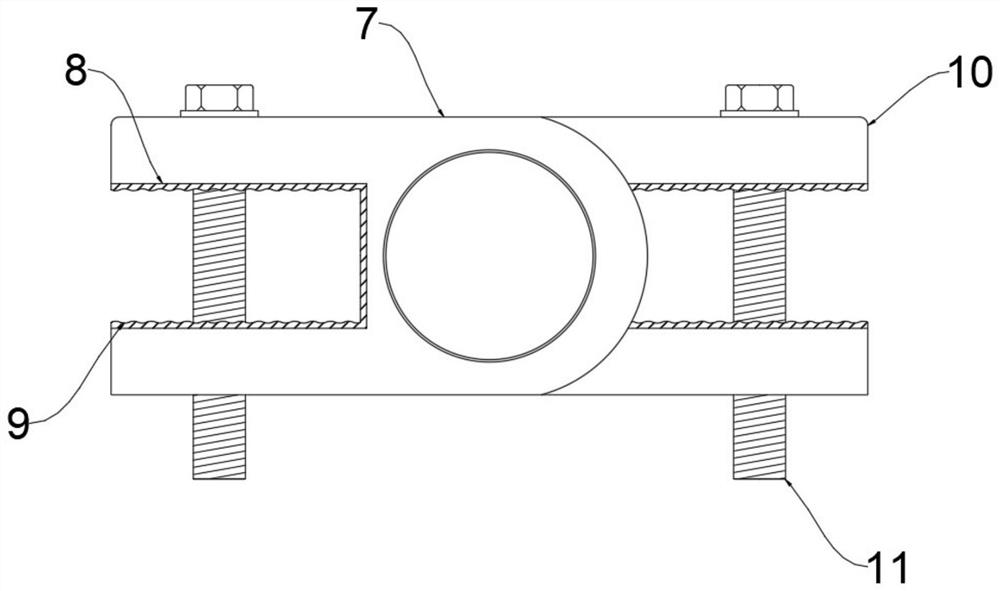

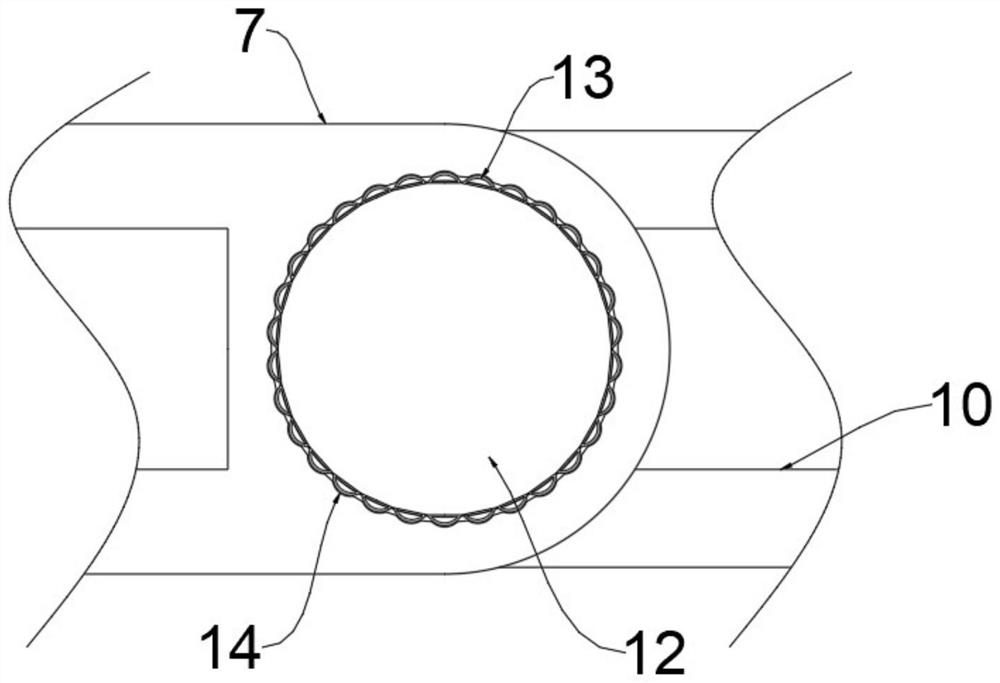

[0026] see Figure 1-5 , an embodiment provided by the present invention: a heat insulating material and its connection device, including a body 1 and a connection device 7, the body 1 is composed of an aluminum foil heat insulation layer 2, a rubber and plastic sponge 3 and an expanded polystyrene board 5, and The aluminum foil insulation layer 2, the rubber-plastic sponge 3 and the expanded polystyrene board 5 are fixed by adhesive 4, and the rubber-plastic sponge 3 is made of EPDM rubber, stearic acid, semi-reinforced furnace black, calcium carbonate, Paraffin oil, zinc oxide, calcium oxide, sulfur, accelerator and foaming agent are sequentially put into the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com