Chlorination furnace for fine-fraction titanium-rich material and fluidizing chlorination process thereof

A boiling chlorination and chlorination furnace technology, applied in the direction of titanium tetrachloride, titanium halide, etc., can solve the problems that affect the technical and economic indicators of the boiling chlorination process of titanium-rich materials, many micropores, and small bulk density. , to achieve the effect of light weight, increased chlorination rate and product yield, and easy overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

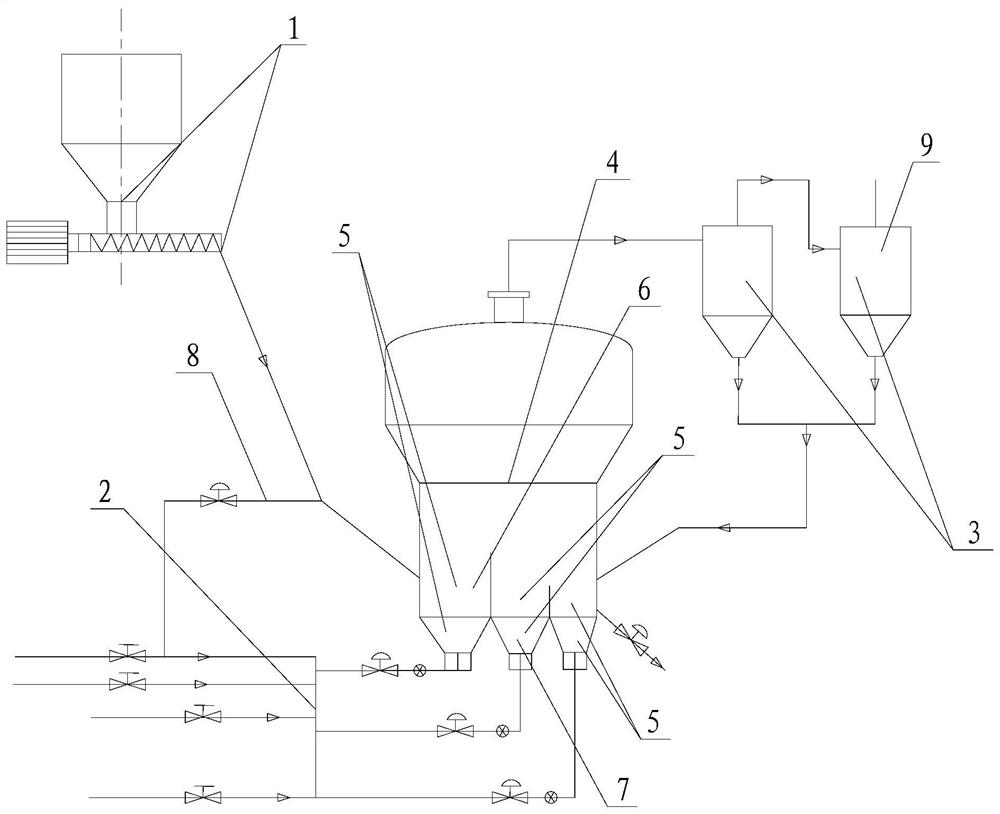

[0050] Such as figure 1 As shown, the main process links of the present invention include: furnace start-up, feed control, reaction and temperature control, slag discharge, dust collection, TiCl4 collection and tail gas treatment. The supporting equipment mainly includes: feeding system, chlorination reactor, dust collection system, TiCl4 collection system, tail gas treatment system. The chlorination reactor is divided into multiple chlorination units, and each chlorination unit contains a gas premix chamber, a gas distributor, a reaction section, a transition section, and a settling section. Each unit has an independent gas supply system, and each gas supply system includes chlorine gas inlet, inert gas inlet (preferably nitrogen), air or oxygen inlet according to needs.

[0051] According to the characteristics of chlorination, the start-up of the furnace is divided into two stages. The first stage is the low-temperature oven stage, which is mainly aimed at the start-up of ...

Embodiment 1

[0090] Start-up: In this embodiment, the refractory lining of the fluidized chlorination furnace is remade.

[0091] ① First, open the air (oxygen) automatic regulating valve and gas automatic regulating valve of the first chlorination unit in sequence, light the burner, control the temperature of the gas premixing room at 100-150°C, control the ratio of air and gas at 4:1, and turn on The nitrogen automatic regulating valve controls the total gas volume entering the fluidized chlorination furnace at 300-350Nm3 / h, and bakes the first chlorination unit of the fluidized chlorination furnace.

[0092]②According to the requirements of the refractory material lining the fluidized chlorination furnace, adjust the gas flow rate and gradually increase the gas temperature. When the gas temperature exceeds 500°C, increase the opening of the automatic air regulating valve and increase the air flow rate. The air volume is controlled at 300Nm3 / h , gradually open the feeding screw of the fe...

Embodiment 2

[0101] Start-up of the furnace: In this embodiment, the furnace is started up when the temperature in the furnace is relatively high after the equipment failure occurs in the system and the furnace is shut down for quick processing.

[0102] Turn on the air automatic regulating valve and coal gas automatic regulating valve in the gas supply device of each chlorination unit in turn, ignite the gas premixing room burner, the ratio of air to gas is 4:1, control the temperature of the gas premixing and setting room at 300-450°C, and control The total gas volume of the primary chlorination unit is 250-300Nm3 / h, the total gas volume of the secondary chlorination unit is 200-250Nm3 / h, the total gas volume of the tertiary chlorination unit is 150-200Nm3 / h, and the boiling chlorination furnace is quickly baked.

[0103] When the gas temperature of the first chlorination unit exceeds 500°C, increase the opening of the automatic air regulating valve, increase the air flow, control the air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com