Preparation method of coal gangue microbial fertilizer

The technology of a microbial fertilizer and a production method is applied in the production field of coal gangue microbial fertilizer, and can solve the problems of low carbon content, bulging, pulverization and the like, and achieve the effect of improving the phosphorus absorption coefficient, simple and reliable process, and improving ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The separation of spindle-shaped lysine bacillus GZU-Lys01 comprises the following steps:

[0025] 1. Isolation and screening of functional strain GZU-Lys01

[0026] 1) Collection of samples

[0027] (1) The sample was collected from a coal gangue hill in a coal production area, and the fully weathered gangue sample and nearby soil samples were selected, and the collected samples were put into a collection bag;

[0028] (2) crush and sieve the sample collected, and collect a 100-mesh sample;

[0029] (3) Store the samples in a refrigerator at 4°C for later use.

[0030] 2) Screening of functional strains

[0031] (1) Accurately weigh 1g of sample into a sterilized 250mL Erlenmeyer flask, and add 99mL of sterile water;

[0032] (2) Shake in a constant temperature shaker at 180r / min, 27°C for 30min;

[0033] (3) After shaking for 30 minutes, take the supernatant and dilute to 1.0×10 -2 , 1.0×10 -3 , 1.0×10 -4 , 1.0×10 -5 , 1.0×10 -6 , 1.0×10 -7 .

[0034] (4) ...

Embodiment 2

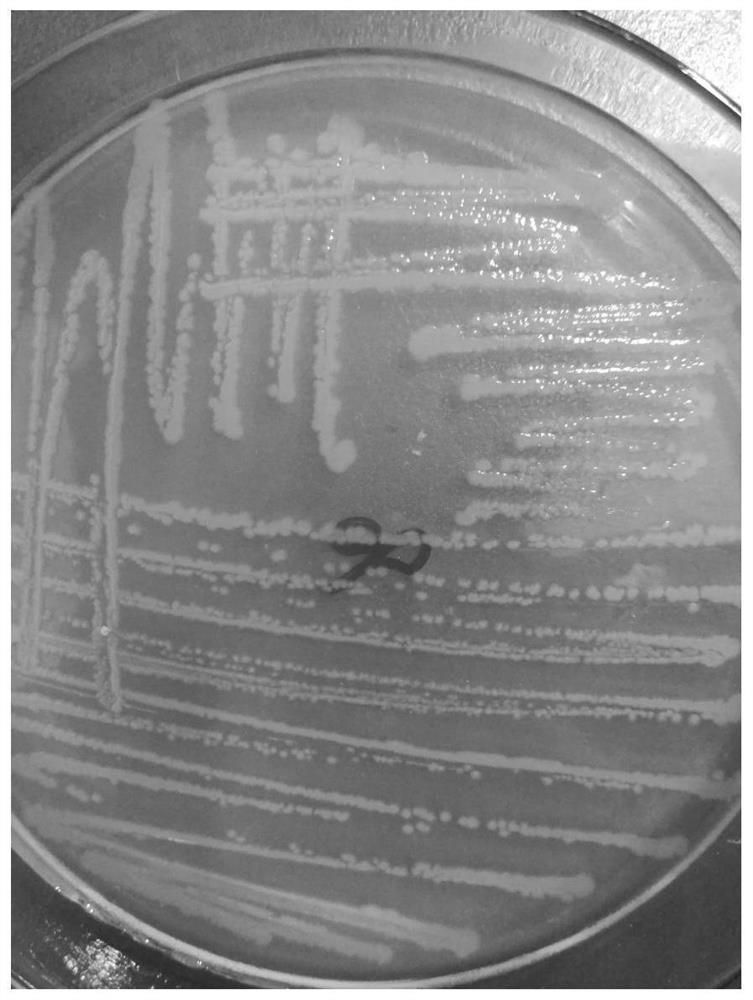

[0046] Embodiment 2: GZU-Lys01 bacterial strain appearance morphology and Gram staining

[0047] The appearance of the colony of the strain on LB solid medium is milky white, opaque and round, with a smooth and moist surface, the colony is raised, shiny, with neat edges and sticky texture. Its size is about 1mm, see figure 2 .

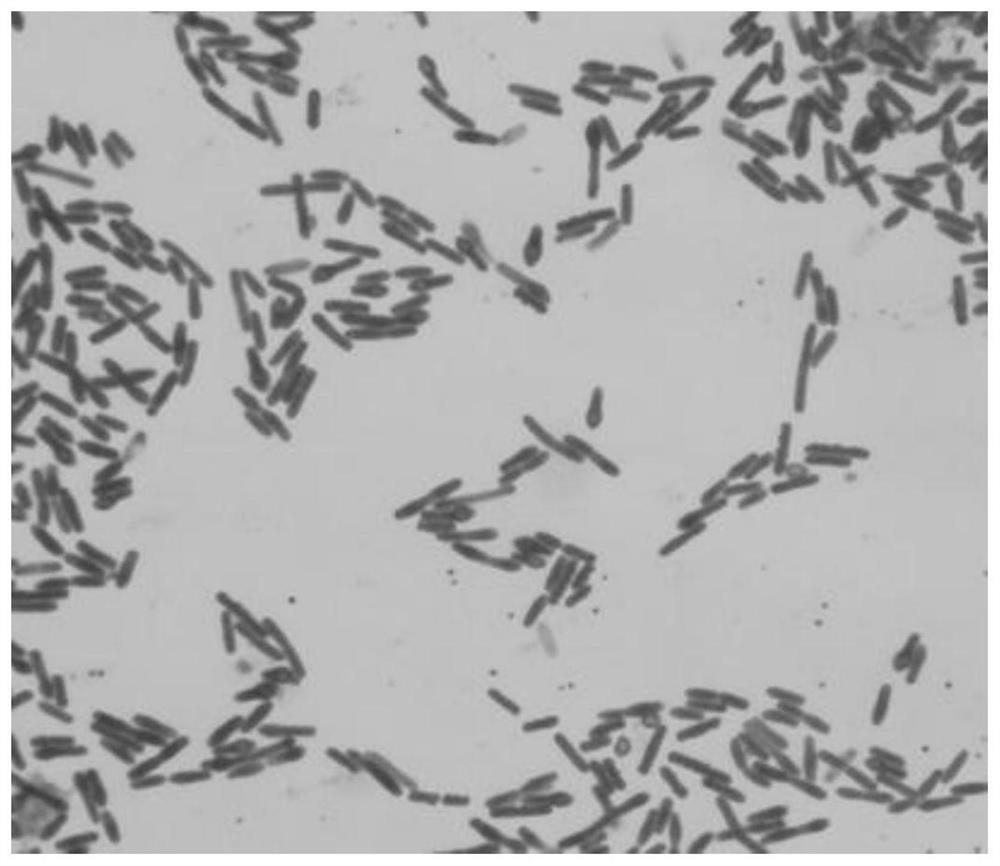

[0048] By Gram staining, the morphology of the bacteria is as follows image 3 , the strain is a Gram-positive bacillus.

Embodiment 3

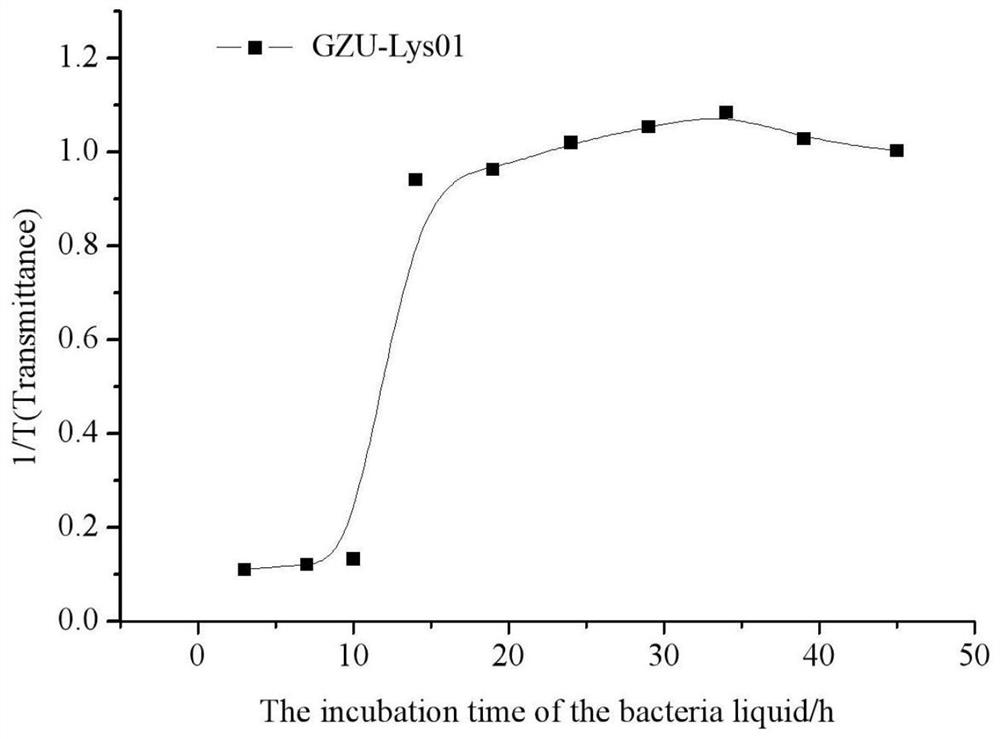

[0049] Embodiment 3: the cultivation of GZU-Lys01 bacterial strain

[0050] 1) Under sterile conditions, thaw the GZU-Lys01 strain at room temperature.

[0051] 2) After thawing, under aseptic conditions, shake well, absorb the GZU-Lys01 bacterial solution into the LB solid medium, spread it evenly, and place it in a constant temperature incubator at 35°C for 24-48h.

[0052] 3) Under sterile conditions, pick a single colony with an inoculation loop and inoculate it in LB solid medium by streaking method under sterile conditions, and place it in a constant temperature incubator at 35°C for 24-48 hours.

[0053]4) After the bacteria grow well, under aseptic conditions, use sterile water to elute the grown bacteria in the culture medium to obtain the bacteria liquid, and the concentration range of the bacteria liquid is controlled at: 1.05×10 10 -3.52×10 10 cfu / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com