A kind of clothing fragrance composition and preparation method thereof

A technology for composition and fragrance retention, which is applied in the preparation of detergent mixture compositions, softening compositions, deodorant compositions, etc., which can solve the problem that the softness and toughness of clothing fibers are greatly affected, and the sweat odor cannot be completely covered , Clothing effect is not good and other problems, to achieve the effect of prolonging the fragrance retention time, promoting the effect of clothing protection, and enhancing the residual amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

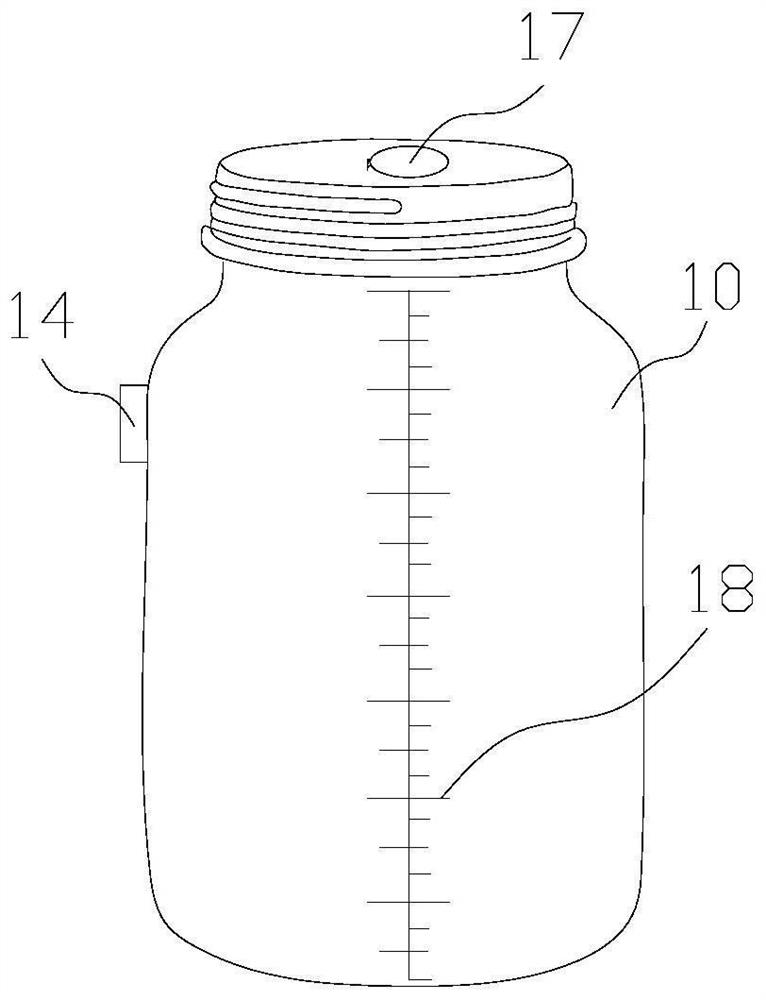

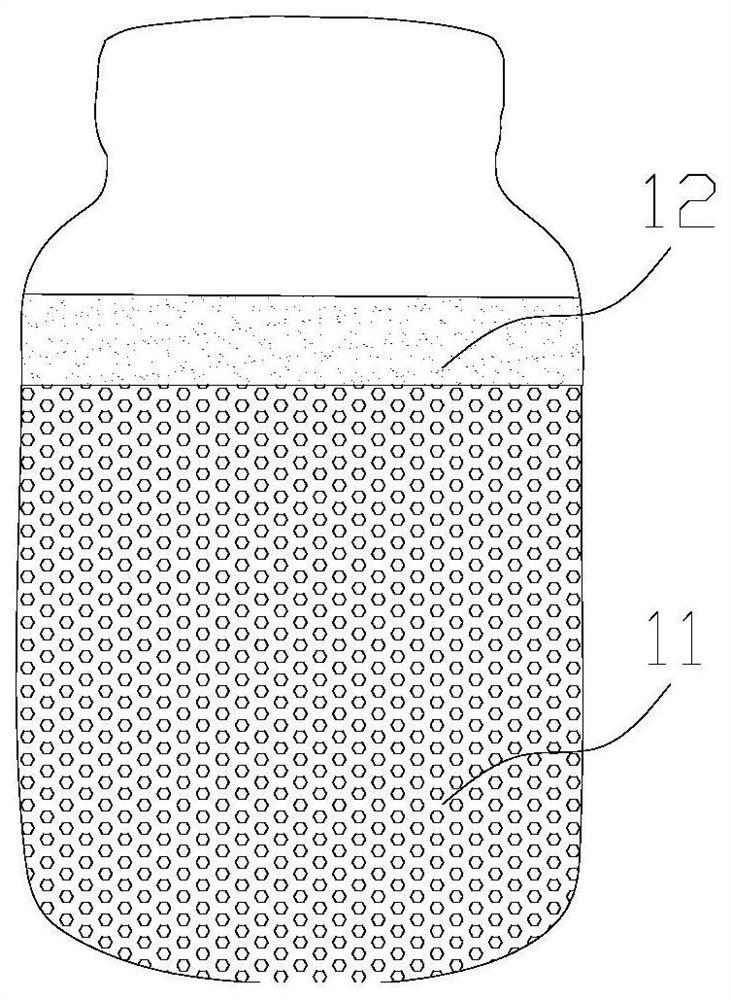

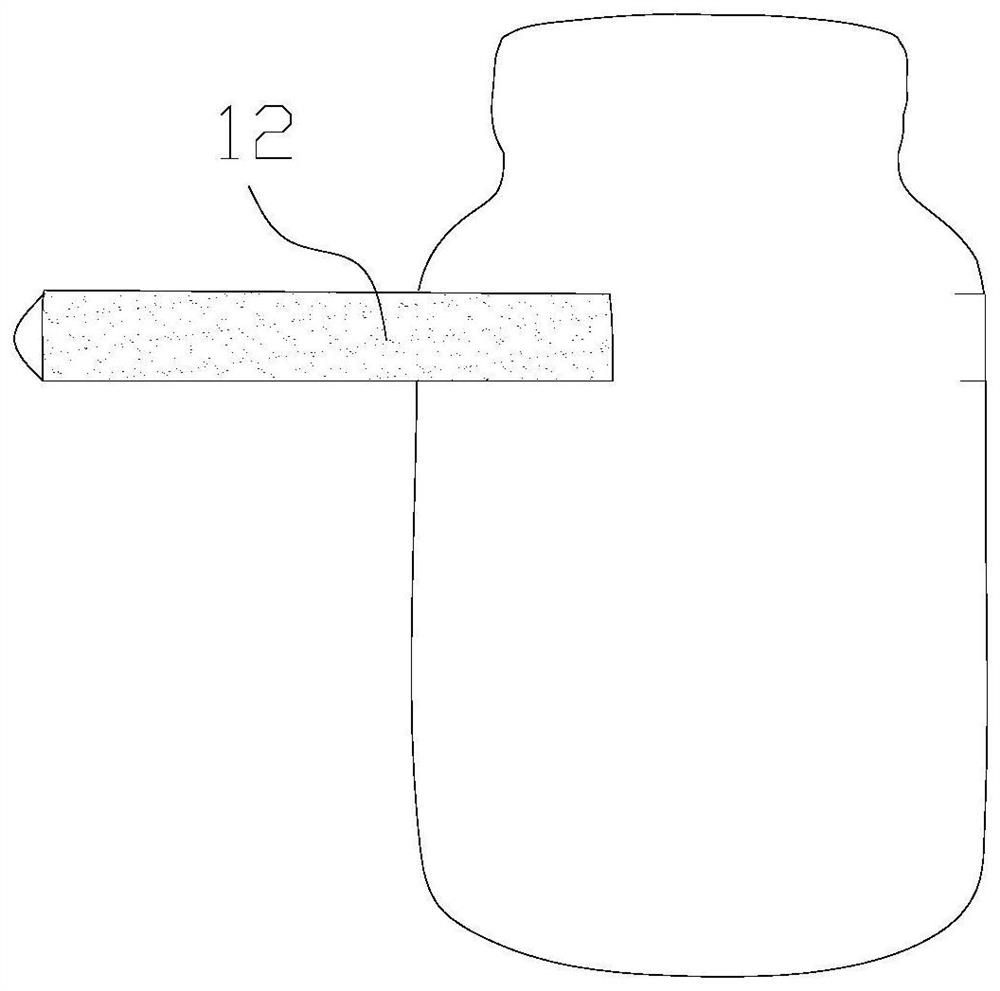

[0039] Such as Figure 1-4 As shown, a clothing fragrance composition 11 includes a packaging bottle 10 and a fragrance composition 11, and the fragrance composition 11 is arranged in the packaging bottle 10; the fragrance composition 11 includes the following components by weight percentage: Polyethylene glycol 75%; fatty alcohol polyoxyethylene ether 5%; sodium sulfate 1%; liquid flavor 4%; flavor microcapsules 8%; starch 3%; kaolin 3.8%; butylated hydroxytoluene 0.05%; 0.1%; Pigment 0.05%; The sum of the weight percentages of the above components is 100%.

[0040] The clothing fragrance composition is prepared according to the following method:

[0041] Blending and melting: Add the formula amount of polyethylene glycol into the batching tank, heat to 80-85°C, cool down to 70-75°C after the polyethylene glycol dissolves, then add the formula amount of sink-float regulator, sodium sulfate, Liquid essence, essence microcapsules, starch, kaolin, butylated hydroxytoluene, dic...

Embodiment 2

[0048] The difference between Example 2 and Example 1 is that the fragrance-keeping composition 11 includes the following components by weight percentage: polyethylene glycol 80%; fatty alcohol polyoxyethylene ether 10%; sodium sulfate 2%; liquid 2% essence; 1% essence microcapsule; 1.55% starch; 3% kaolin; 0.3% butylated hydroxytoluene; 0.05% dichlorobenzyl alcohol; 0.1% pigment;

Embodiment 3

[0050] The difference between Example 3 and Example 1 is that the fragrance-keeping composition 11 includes the following components in terms of weight percentage: polyethylene glycol 85%; fatty alcohol polyoxyethylene ether 5%; sodium sulfate 1%; liquid Essence 1%; essence microcapsules 3%; starch 1.95%; kaolin 1.8%; butylated hydroxytoluene 0.05%; dichlorobenzyl alcohol 0.1%; pigment 0.05%; The sum of the weight percentages of the components is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com