High-dose yield circumferential irradiation ray tube

A high-dose, X-ray tube technology, applied in X-ray tube electrodes, X-ray tube components, X-ray tube shells/containers, etc., can solve the problems affecting the reliability and service life of the X-ray tube In order to improve the service life, materials with high conversion efficiency and optimize the thickness of radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

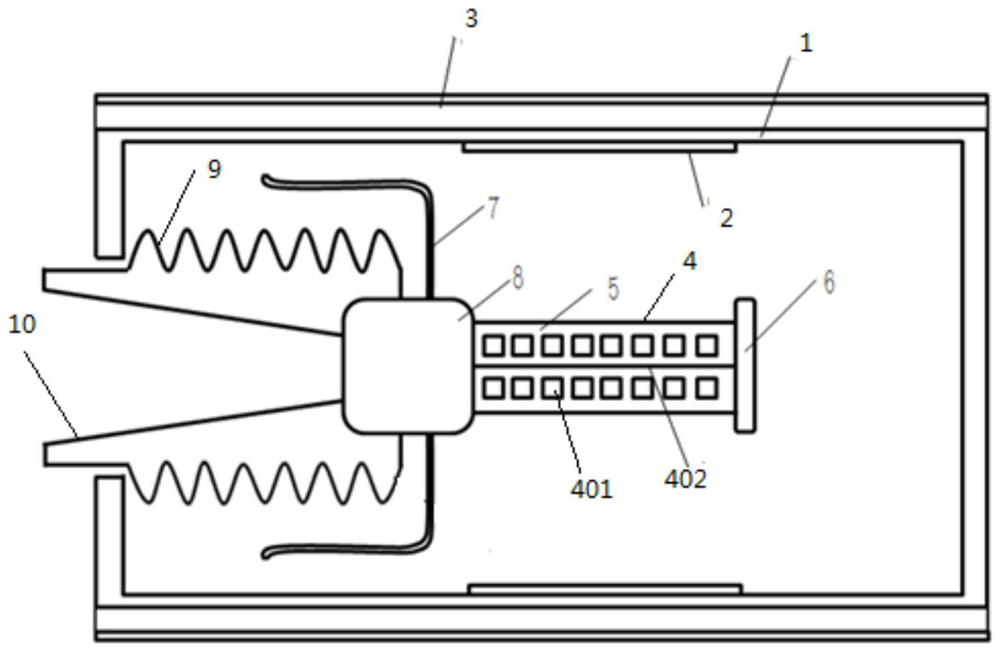

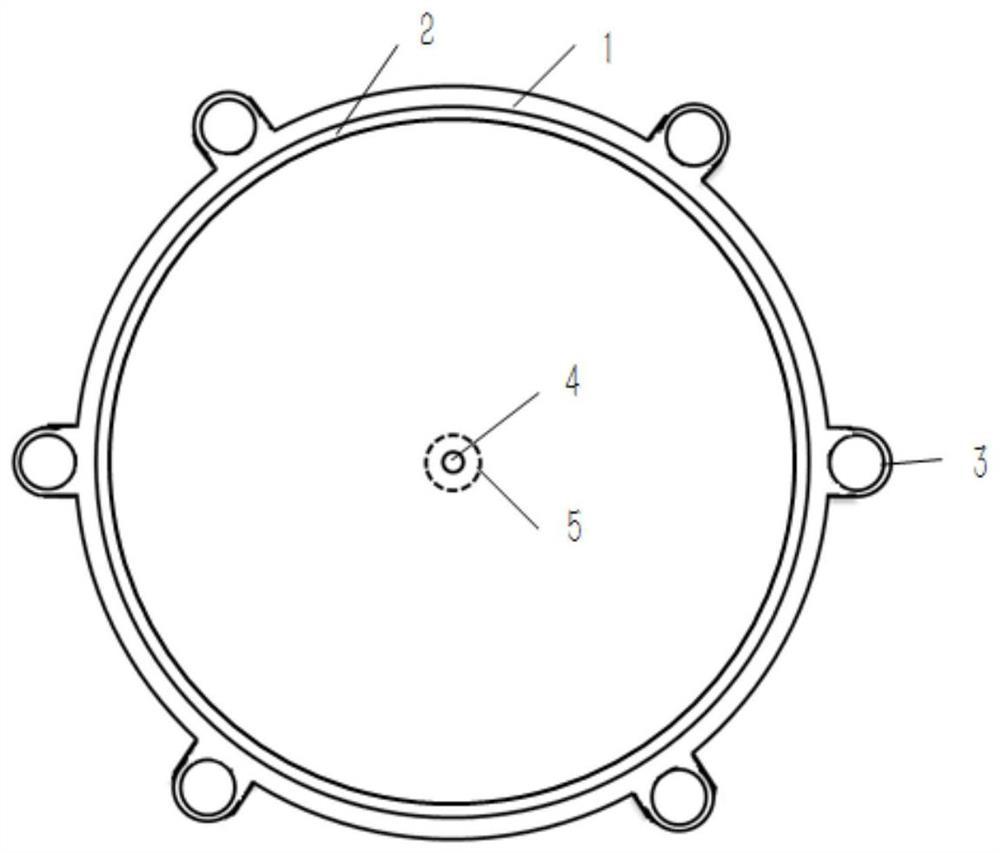

[0029] Such as Figure 1~2 As shown, the high-dose yield circumferential radiation irradiation tube of the present invention includes a cylindrical support base 1, a plurality of cooling pipes 3 are arranged on the outside of the support base 1, and a circle of radiation conversion targets 2 is arranged on the inside, The support base 1 is used as a supporting structure and a direct heat dissipation part, and is made of high-strength and high heat transfer coefficient materials, such as high-purity oxygen-free copper, pure copper, and copper alloy; its structural design meets the insulation design and vacuum design requirements of electric vacuum devices, At the same time, it is necessary to meet the dose rate requirements of the radiation. The thickness of the cylinder is about 1-5mm, the inner diameter is about 100-200mm, and the height is about 200-500mm. , aluminum, fully in contact with the support base, preferably using the same material as the support base 1 and forming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com