A flexible and stretchable zinc-air battery based on foam-based metal electrodes and its preparation

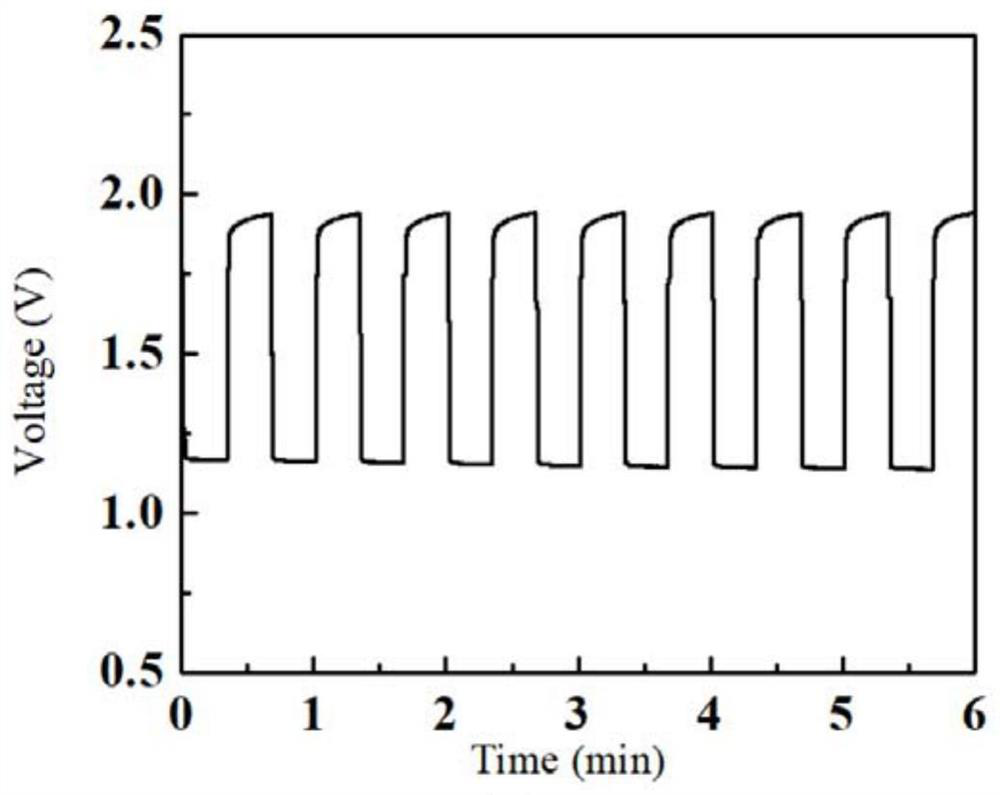

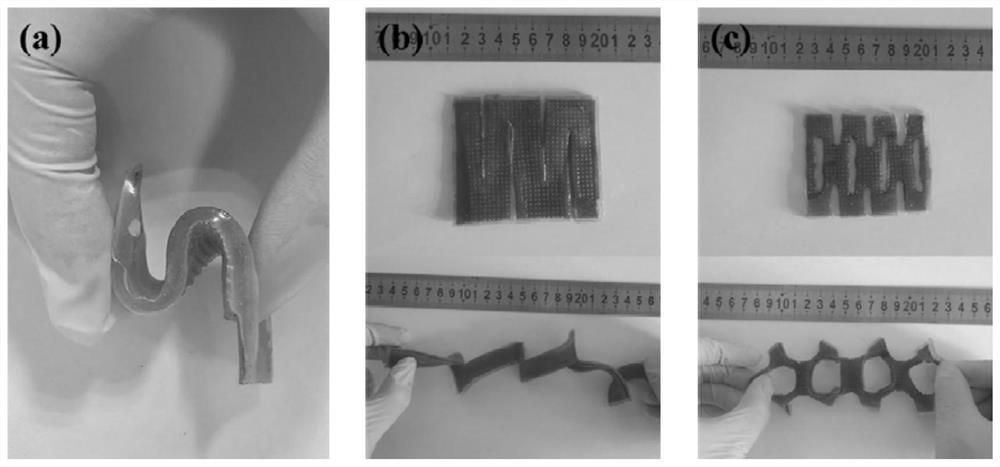

A zinc-air battery and base metal technology, which is applied in the direction of electrical components, battery electrodes, fuel cell half-cells, and primary battery-type half-cells, can solve the problems of small specific surface area and lack of flexibility of electrodes, and achieve preparation The method is simple, the cost is low, and the effect of stable charging and discharging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of the copper-plated / nickel sponge layer comprises the following steps:

[0057] A1. Cut the sponge film into small pieces, and dry them completely after ultrasonic cleaning;

[0058] A2. Stick the dried sponge film on the rubber film, and then solidify to obtain a bonded sponge-rubber film;

[0059] A3. Put the bonded sponge-rubber film in SnCl 2 Vacuum immersion in hydrochloric acid solution for 10-60min, take out and then immerse in PdCl 2 Vacuum immersion in hydrochloric acid solution for 10-60min, take out, freeze-dry to obtain surface-activated sponge-rubber film;

[0060] A4. Soak the surface-activated sponge-rubber film in an electroless copper plating solution or a nickel plating solution to deposit metallic copper or nickel on the surface to form a copper plating or nickel plating layer to obtain a copper / nickel sponge layer.

[0061] In step A1, the sponge film is a polyurethane sponge film with a thickness of 0.1-1mm;

[0062] In s...

Embodiment 1

[0084] This embodiment provides a preparation method of a flexible stretchable zinc-air battery based on a foam-based metal electrode, comprising the following steps:

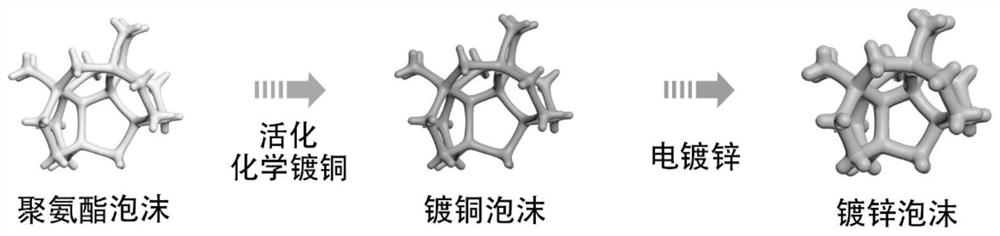

[0085] (1) Preparation of galvanized foam (anode) (eg figure 1 shown):

[0086] 1.1 Mix and stir the Ecoflex-0030 silicone rubber A and B liquids at a weight ratio of 1:1 to form the Ecoflex precursor liquid, pour the Ecoflex precursor liquid into a 1mm deep glass mold, put it in a 60°C oven for 1h, and cross-link and solidify into Ecoflex rubber. film.

[0087] 1.2 The commercial polyurethane sponge film (~1mm thick) was cut into small pieces, ultrasonically cleaned with acetone, ethanol and deionized water for 10 min each, and then placed in a 60°C oven to dry completely.

[0088] 1.3 A piece of dried polyurethane sponge film was adhered to the Ecoflex rubber film with Ecoflex precursor liquid, and cured at 60°C for 30 minutes, and the polyurethane sponge film and the Ecoflex rubber film were tightly bonded...

Embodiment 2

[0103] This embodiment provides a preparation method of a flexible stretchable zinc-air battery based on a foam-based metal electrode, comprising the following steps:

[0104] (1) Preparation of galvanized foam (anode):

[0105] 1.1 Mix and stir the Ecoflex-0030 silicone rubber A and B liquids at a weight ratio of 1:1 to form the Ecoflex precursor liquid, pour the Ecoflex precursor liquid into a 1mm deep glass mold, put it in a 60°C oven for 1h, and cross-link and solidify into Ecoflex rubber. film.

[0106] 1.2 The commercial polyurethane sponge film (~1mm thick) was cut into small pieces, ultrasonically cleaned with acetone, ethanol and deionized water for 10 min each, and then placed in a 60°C oven to dry completely.

[0107] 1.3 A piece of dried polyurethane sponge film was adhered to the Ecoflex rubber film with Ecoflex precursor liquid, and cured at 60°C for 30 minutes, and the polyurethane sponge film and the Ecoflex rubber film were tightly bonded together.

[0108] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com