Method for preparing structural color coating with force-induced discoloration capability

A structural color and color-induced color technology, applied in the field of structural color, can solve the problems of poor water resistance and weather resistance of structural color coatings, destroying the optical properties of coating materials, and destroying the periodic structure of materials. The effect of improving optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

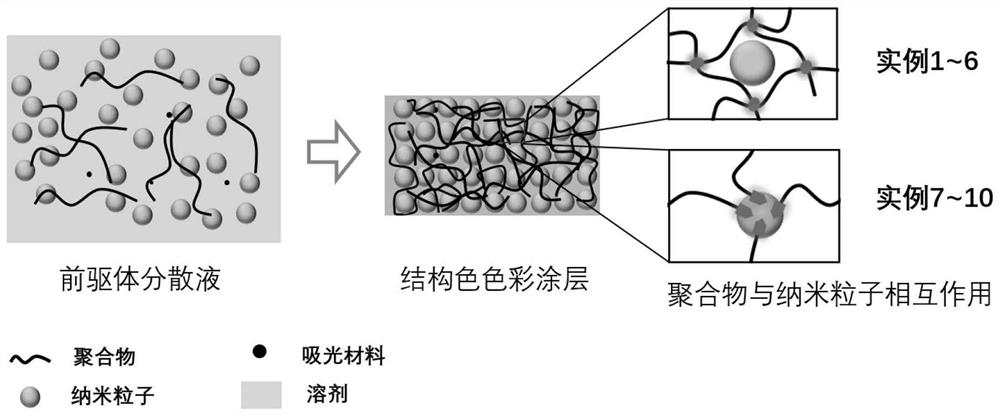

[0038] A method for rapidly preparing a structural color coating with mechanochromic ability on a large scale, comprising the following steps:

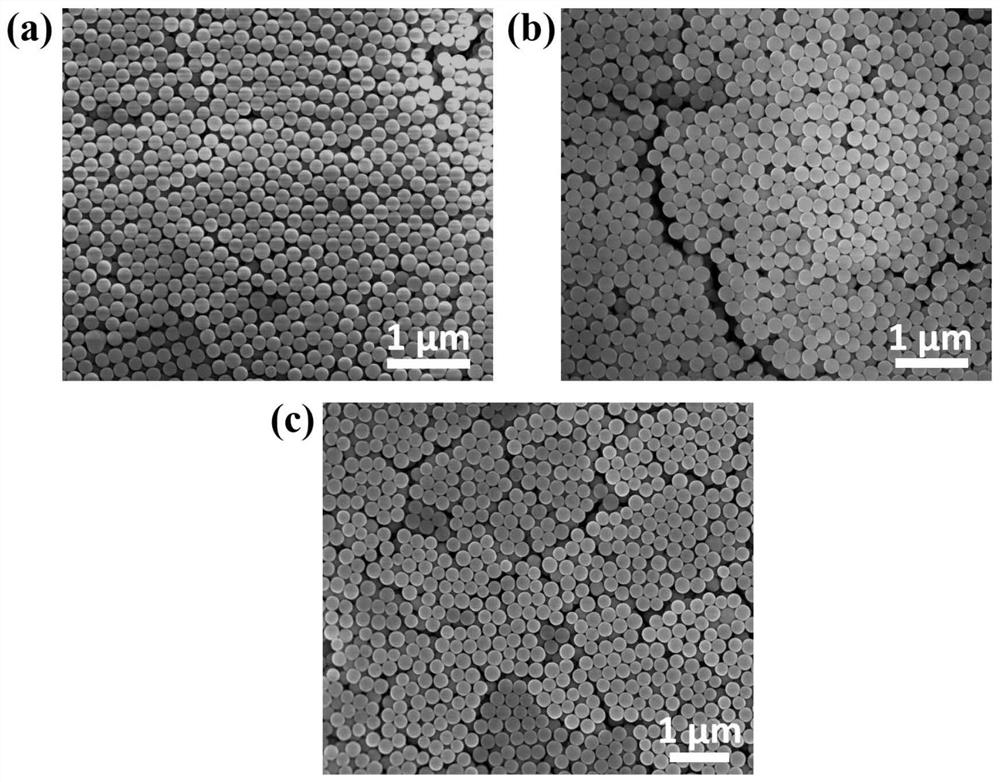

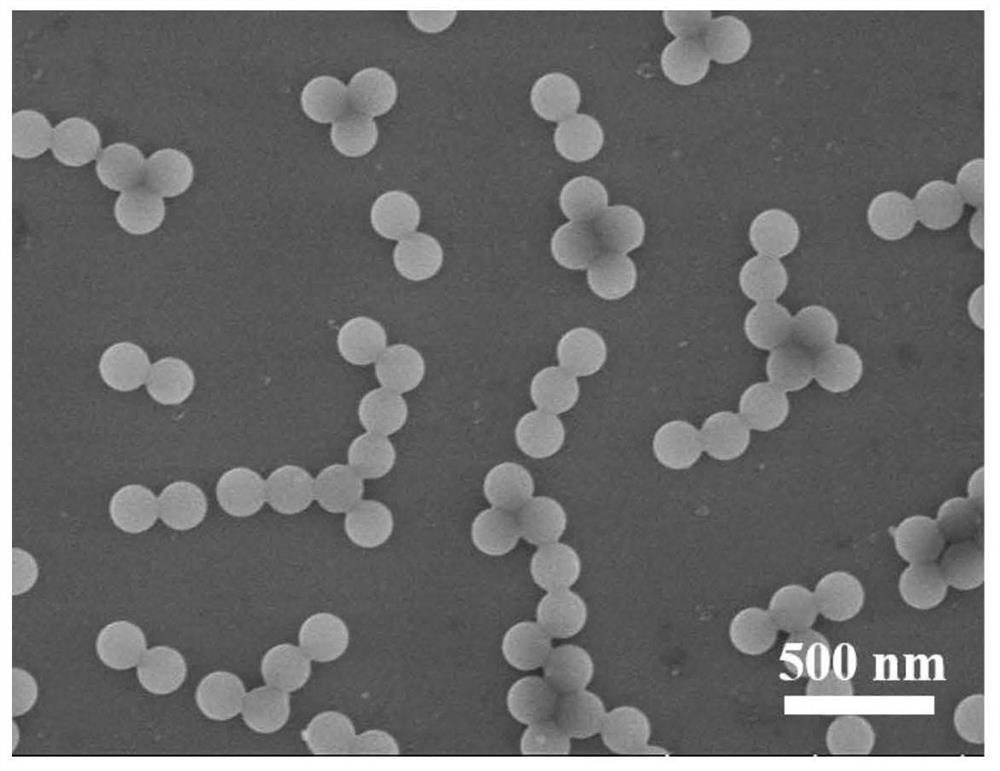

[0039] (1) Polyurethane with a molecular weight of 10000, silicon dioxide nanoparticles with a diameter of 204nm and carbon black nanoparticles with a diameter of 5 to 50nm are dispersed in an ethanol solution by ultrasonic to obtain a precursor dispersion containing 0.005% silicon dioxide and 0.005% polyurethane, Stand still for 2-48 hours (such as 5 hours) to make the nanoparticles and the polymer fully interact; wherein the mass ratio of polyurethane, silicon dioxide nanoparticles and carbon black nanomaterials is 1000:1000:1.

[0040] (2) Pour the precursor dispersion into a spraying container, spray it on the substrate, and obtain a structural color coating with mechanochromic ability at 10°C, and the area of the color coating is determined by the size of the substrate.

Embodiment 2

[0042] A method for rapidly preparing a structural color coating with mechanochromic ability on a large scale, comprising the following steps:

[0043] (1) Polyurethane with a molecular weight of 10000, silicon dioxide nanoparticles with a diameter of 230nm and carbon black nanoparticles with a diameter of 5 to 50nm are dispersed in an ethanol solution by ultrasonic to obtain a precursor dispersion containing 40% silicon dioxide and 50% polyurethane, Stand still for 2 to 48 hours, wherein the mass ratio of polyurethane, silicon dioxide nanoparticles and carbon black nanomaterials is 1000:1000:1.

[0044] (2) Pour the precursor dispersion into a spraying container, spray it on the substrate, and obtain a structural color coating with mechanochromic ability at 30° C., and the area of the color coating is determined by the size of the substrate.

Embodiment 3

[0046] This embodiment includes the following steps:

[0047] (1) Polyurethane with a molecular weight of 50,000, silica nanoparticles with a diameter of 230nm, and carbon black nanoparticles with a diameter of 5 to 50nm are dispersed in an aqueous solution by ultrasonic to obtain a precursor dispersion containing 0.005% silica and 0.001% polyurethane. Place for 2-48 hours, wherein the mass ratio of polyurethane, silicon dioxide nanoparticles and carbon black nanomaterials is 1000:1000:1.

[0048] (2) Inject the precursor dispersion into the mold, and at 50°C, the solvent is firstly volatilized for 8 hours, and then vacuum-dried for 12 hours to obtain a structural color coating with mechanochromic ability. The area of its elastic body is determined by the size of the container device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com