Solvent-free adhesive as well as preparation method and application thereof

An adhesive and solvent-free technology, applied in the direction of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of high cost, complicated preparation process, instability, etc., and achieve high performance Stable, easy to operate, good hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

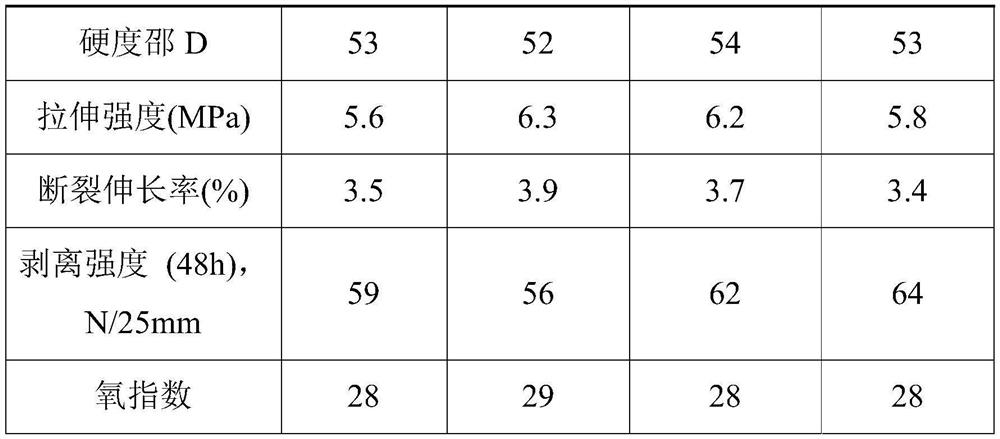

Embodiment 1

[0030] A solvent-free adhesive, including A component and B component, A component includes the following raw materials by weight: 60 parts of epoxy resin, 5 parts of epoxy toughening agent, 10 parts of reactive diluent, 0.3 1 part of reaction accelerator, 0.5 part of thixotropic agent, 0.2 part of substrate wetting agent, 6 parts of wetting and dispersing agent, 18 parts of pigment and filler;

[0031] Component B includes the following raw materials in parts by weight: 95 parts of modified epoxy curing agent and 5 parts of thixotropic agent.

[0032] It should be noted that, in the examples of the present application, the viscosity of the epoxy resin is lower than 10000 mPa·s (25° C.), and epoxy resin E-44 is used as the epoxy resin in the examples of the present application.

[0033] In the embodiment of this application, the epoxy toughening agent can use carboxyl-terminated liquid nitrile rubber (CTBN), amine-terminated liquid nitrile rubber (ATBN), acrylic rubber, silico...

Embodiment 2

[0050] A solvent-free adhesive, including A component and B component, A component includes the following raw materials by weight: 52 parts of epoxy resin, 8 parts of epoxy toughening agent, 8 parts of reactive diluent, 0.2 1 part of reaction accelerator, 0.5 part of thixotropic agent, 0.3 part of substrate wetting agent, 8 parts of wetting and dispersing agent, 23 parts of pigment and filler;

[0051] Component B includes the following raw materials in parts by weight: 90 parts of modified epoxy curing agent and 10 parts of thixotropic agent.

[0052] It should be noted that, in the embodiment of the present application, the viscosity of the epoxy resin is lower than 10000 mPa·s (25° C.), and epoxy resin 170 is used as the epoxy resin in the embodiment of the present application.

[0053] In the embodiment of this application, the epoxy toughening agent can use carboxyl-terminated liquid nitrile rubber (CTBN), amine-terminated liquid nitrile rubber (ATBN), acrylic rubber, sil...

Embodiment 3

[0068] A solvent-free adhesive, including A component and B component, A component includes the following raw materials by weight: 40 parts of epoxy resin, 6 parts of epoxy toughening agent, 10 parts of reactive diluent, 0.3 parts 1 part of reaction accelerator, 0.5 part of thixotropic agent, 0.2 part of substrate wetting agent, 9 parts of wetting and dispersing agent, 34 parts of pigment and filler;

[0069] Component B includes the following raw materials in parts by weight: 92 parts of modified epoxy curing agent and 8 parts of thixotropic agent.

[0070] It should be noted that, in the examples of the present application, the viscosity of the epoxy resin is lower than 10000 mPa·s (25° C.), and the epoxy resin in the examples of the present application is epoxy resin NHR-154.

[0071] In the embodiment of this application, the epoxy toughening agent can use carboxyl-terminated liquid nitrile rubber (CTBN), amine-terminated liquid nitrile rubber (ATBN), acrylic rubber, silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com