A carbon fiber production process capable of eliminating static electricity

A production process and technology for eliminating static electricity, which is applied in the direction of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of unfavorable raw silk unorientation, unfavorable guarantee of carbon fiber quality, and inability to guarantee the strength of raw silk, so as to ensure quality and eliminate The effect of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

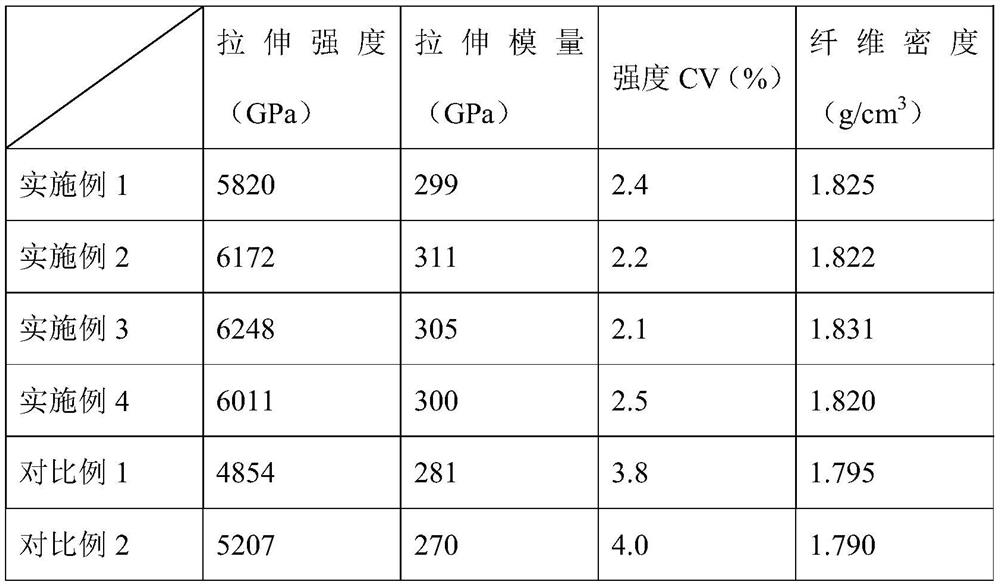

Examples

Embodiment 1

[0028] With 96%wt acrylonitrile, 1%wt itaconic acid, 3%wt styrene sulfonic acid as comonomer, carry out solution polymerization reaction under the effect of solvent and initiator, obtain copolymer; The polymer obtained by polymerization reaction Carry out wet spinning to obtain the original silk; dissolve benzyltriethylammonium chloride in water, configure a solution with a mass concentration of 1%wt, soak the original silk in the benzyltriethylammonium chloride aqueous solution for 2min, Remove to dry.

[0029] The raw silk is dried in a horizontal drying furnace, the drying temperature is 80°C, and the drying time is 30 minutes. After drying, the raw silk with a water content of ≤1% is obtained; the dried raw silk and the raw silk are sent to a pre-oxidation furnace for pre-oxidation. Oxidation, there are 3 pre-oxidation furnaces in a row, the temperature ranges of the 3 pre-oxidation furnaces are 180-230°C, 220-260°C, 255-265°C respectively, and the pre-oxidation time is 15...

Embodiment 2

[0032] With 97%wt acrylonitrile, 2%wt itaconic acid, 1%wt styrene sulfonic acid as comonomer, carry out solution polymerization reaction under the effect of solvent and initiator, obtain copolymer; The polymer obtained by polymerization reaction Carry out wet spinning to obtain raw silk; dissolve tetrabutylammonium hydrogen sulfate in water to prepare a solution with a mass concentration of 0.5% wt, soak the raw silk in tetrabutylammonium hydrogen sulfate aqueous solution for 1 min, take it out and dry it in the air.

[0033] The raw silk is dried in a horizontal drying furnace, the drying temperature is 100°C, and the drying time is 25 minutes. After drying, the raw silk with a water content of ≤ 1% is obtained; the dried raw silk and the raw silk are sent to a pre-oxidation furnace for pre-oxidation. Oxidation, there are 3 pre-oxidation furnaces in a row, the temperature ranges of the 3 pre-oxidation furnaces are 180-230°C, 220-260°C, 255-265°C respectively, and the pre-oxida...

Embodiment 3

[0036] Except that the comonomer is composed of 97.5%wt acrylonitrile, 2%wt itaconic acid and 0.5%wt styrenesulfonic acid, other conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com