A kind of aviation tire tread rubber and its preparation method and application

A technology for aviation tires and tread rubber, used in special tires, tire parts, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention provides the preparation method of the aviation tire tread rubber described in the above scheme, comprising the following steps:

[0056] Mix the natural rubber masticated rubber. When the mixing temperature rises to 90~95℃, add multi-wall carbon nanotubes, multifunctional vulcanization activator and heat stabilizer to continue mixing. When the mixing temperature rises from 90~95℃ When the temperature rises from 95°C to 100-105°C, add medium and super wear-resistant carbon black, silica wet-process adhesive and silane coupling agent to continue mixing. When the mixing temperature rises from 100-105°C to 140-145°C, mix The obtained mixture is sliced, cooled and parked to obtain a section of mixed rubber;

[0057] Mixing the first-stage rubber compound, anti-tear resin, zinc oxide and anti-aging agent, when the mixing temperature rises to 120-125° C., the obtained mixture is cut into pieces, cooled and parked to obtain a second-stage rubber compound...

Embodiment 1~3

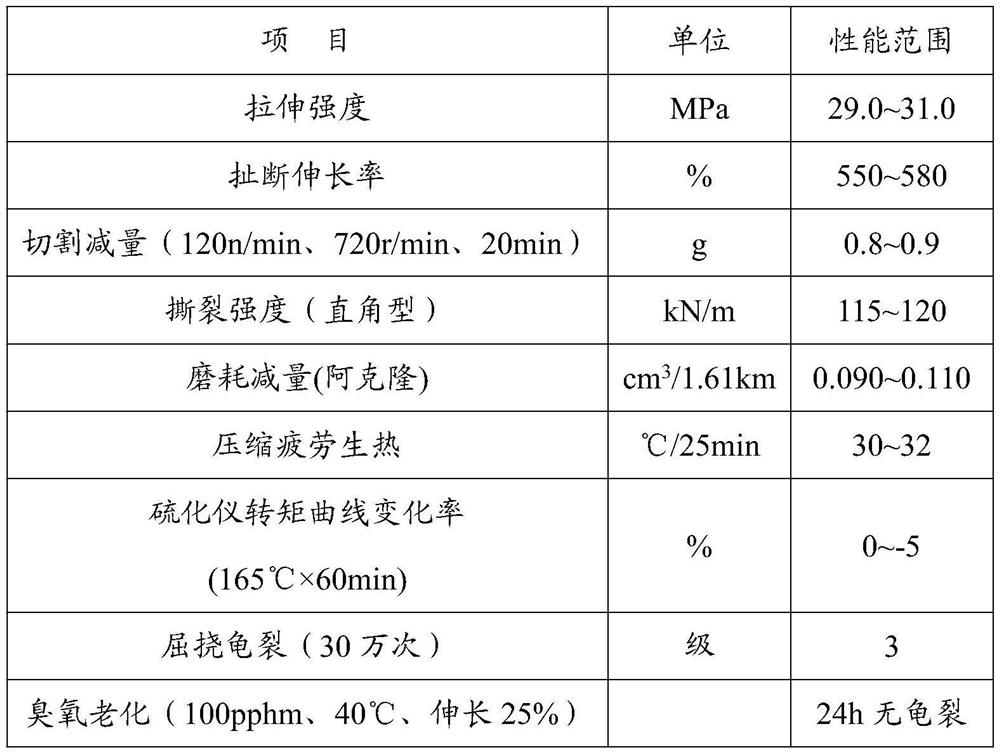

[0067] The preparation raw materials of Examples 1-3 are shown in Table 4.

[0068] The preparation method of aviation tire tread rubber is as follows:

[0069] A blend:

[0070] Put the natural rubber masticated rubber into the internal mixer, and the mixing temperature is raised from 80 °C to 90 °C; put the multi-walled carbon nanotubes, multi-functional vulcanization activators, and heat stabilizers into the internal mixer according to the proportion, and mix and mix. The mixing temperature is raised from 90°C to 100°C; the super wear-resistant carbon black, white carbon black wet-process adhesive, and silane coupling agent are put into the internal mixer in proportion, and mixed and mixed, and the mixing temperature is from 100°C to 100°C. 140°C; when the mixing temperature reaches 140°C, the mixture is discharged from the internal mixer to the upper and lower tablets of the tablet press, cooled, and parked for 16 hours to obtain a section of mixed rubber.

[0071] Two-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com