Hot-melt three-proofing paint as well as preparation method and use method thereof

A conformal paint and hot-melt technology, applied in coatings, devices for coating liquids on the surface, etc., can solve problems such as coating solvent environmental pollution, and achieve the effects of cost saving, easy renovation, and safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

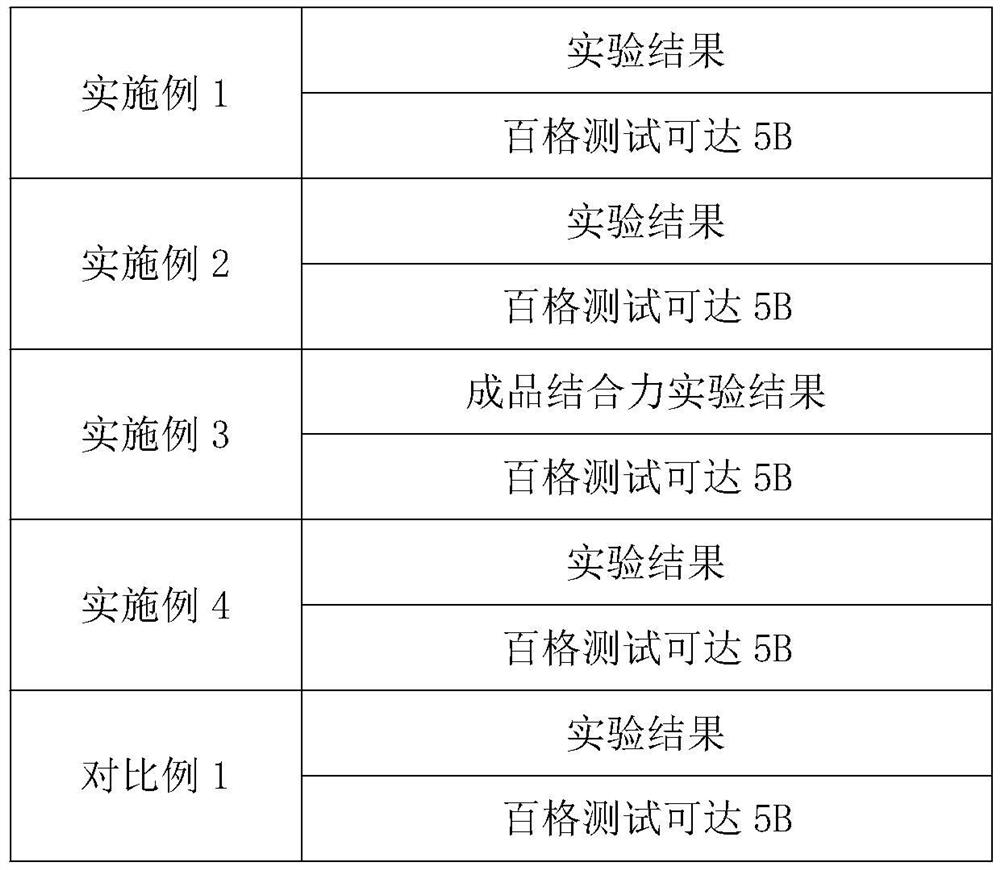

Examples

Embodiment 1

[0028] A method for preparing a hot-melt three anti-paint, comprising the following steps:

[0029] Step 1. Perform ring-opening reaction at 100° C. for 3 hours with succinic anhydride and polyethylene glycol in a molar ratio of 1:2.0;

[0030] Step 2, when the acid value of the detection system reaches the theoretical value, add 1.5 times the liquid epoxy resin and 3% n-butylammonium bromide catalyst of the molar number of succinic anhydride, and react at 120 ° C for 3.5 h, measure the acid value of the resin to below 5mgKOH / g, and cool down to obtain a toughening agent;

[0031] Step 3. Heating β-(3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate, C5 petroleum resin and polyethylene to melt respectively, and the melting temperature is 190°C;

[0032] Step 4, the melted β-(3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate, C5 petroleum resin, and polyethylene are respectively proportioned according to the dosage of 1%, 30%, 65% % mixed, and fully stirred, until th...

Embodiment 2

[0037] A method for preparing a hot-melt three anti-paint, comprising the following steps:

[0038] Step 1. Perform ring-opening reaction at 100° C. for 3 hours with succinic anhydride and polyethylene glycol in a molar ratio of 1:2.0;

[0039] Step 2, when the acid value of the detection system reaches the theoretical value, add 1.5 times the liquid epoxy resin and 3% n-butylammonium bromide catalyst of the molar number of succinic anhydride, and react at 120 ° C for 3.5 h, measure the acid value of the resin to below 5mgKOH / g, and cool down to obtain a toughening agent;

[0040] Step 3. Heating β-(3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate, polyα-methylstyrene resin, and polypropylene to melt respectively, and the melting temperature is 190°C ;

[0041] Step 4: Mix the melted β-(3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate, poly-α-methylstyrene resin, and polypropylene according to the proportion of 1% respectively , 30%, and 65% are mixed, and fully...

Embodiment 3

[0046] A method for preparing a hot-melt three anti-paint, comprising the following steps:

[0047] Step 1. Perform ring-opening reaction at 100° C. for 4 hours with succinic anhydride and polyethylene glycol in a molar ratio of 1:2.0;

[0048] Step 2, when the acid value of the detection system reaches the theoretical value, add 1.5 times the liquid epoxy resin and 5% n-butyl ammonium bromide catalyst of the molar number of succinic anhydride, and react at 100 ° C for 3.5 h, measure the acid value of the resin to below 5mgKOH / g, and cool down to obtain a toughening agent;

[0049] Step 3. Heating β-(3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate, C5 petroleum resin, and poly-1-butene to melting respectively, and the melting temperature is 190°C;

[0050] Step 4, the melted β-(3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate, C5 petroleum resin, and poly-1-butene are respectively proportioned according to the dosage of 2%, 27 %, 65% mixed, and fully stirred unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com