Novel double-piston two-stroke engine

A dual-piston, two-stroke technology, applied to engine components, machines/engines, pistons, etc., can solve problems such as loss of fresh air mixture, increased fuel and lubricating oil consumption, engine exhaust pollution, etc., to achieve stable operating conditions and structure Compactness, the effect of reducing exhaust emissions and fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

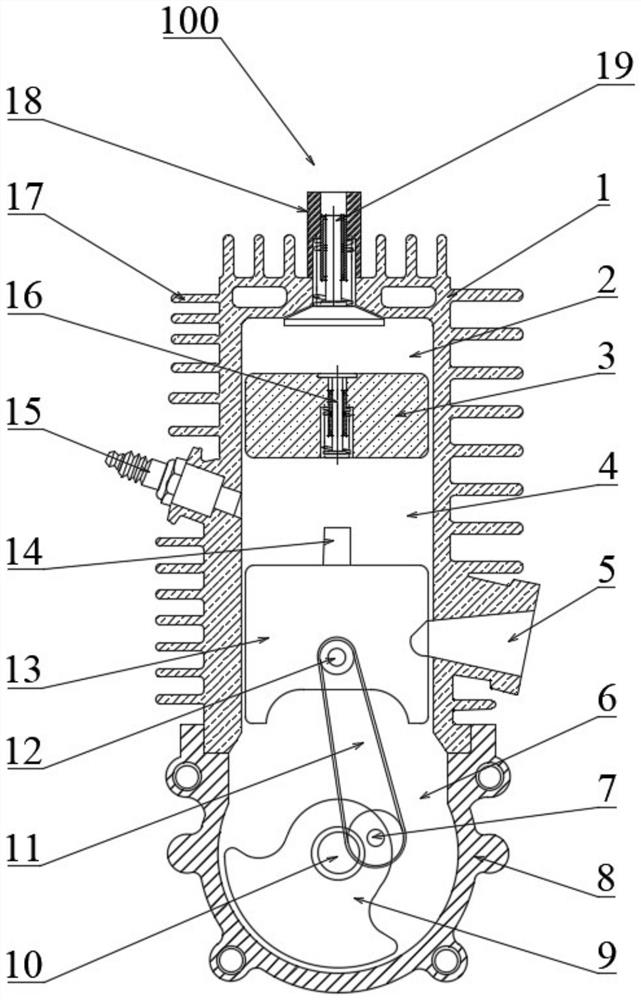

[0026] see figure 1 , image 3 and Figure 4 , the invention discloses a novel double-piston two-stroke engine, comprising a cylinder 1 and a crankcase 8 correspondingly connected to the lower part of the cylinder 1, the first piston 3 and the second piston 13 are set in the cylinder 1 for reciprocating motion; the first The piston 3 and the second piston 13 are arranged correspondingly up and down.

[0027] Specifically, the first piston 3 and the cylinder 1 form a fuel compression chamber 2, and the top of the cylinder 1 is provided with an air inlet 18 corresponding to the fuel compression chamber 2; in a specific implementation, the air inlet 18 is provided with an intake check valve 19, and a fuel intake booster system is arranged corresponding to the intake port 18. The fuel intake booster system communicates with the intake port 18 through a fuel delivery pipe, and the fuel intake booster The system pressurizes fuel such as gasoline mixed with air, and presses it int...

Embodiment 2

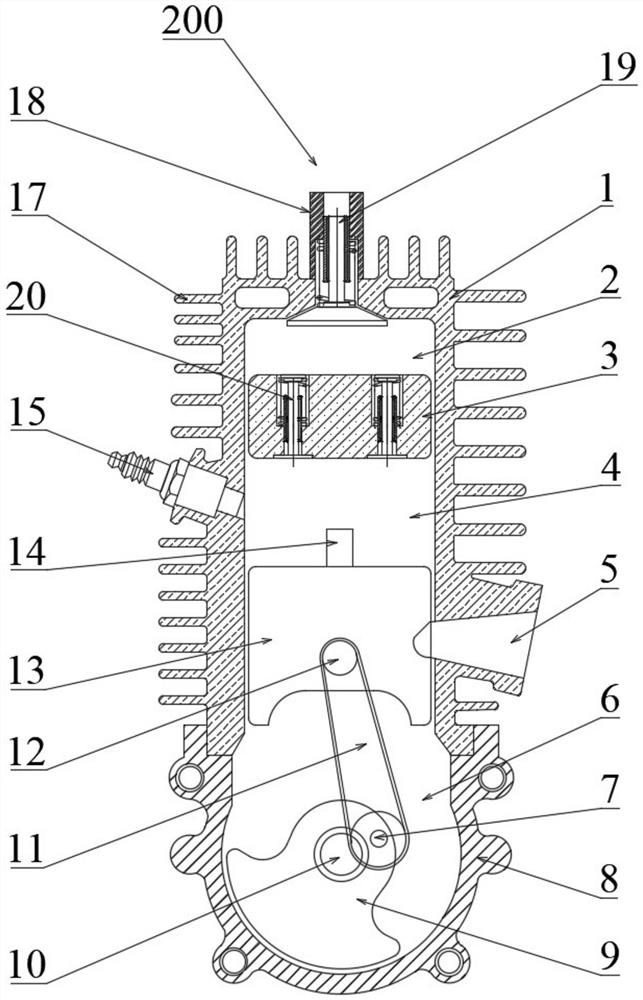

[0034] see figure 2 , image 3 and Figure 5 , the invention discloses a novel double-piston two-stroke engine, comprising a cylinder 1 and a crankcase 8 correspondingly connected to the lower part of the cylinder 1, the first piston 3 and the second piston 13 are set in the cylinder 1 for reciprocating motion; the first The piston 3 and the second piston 13 are arranged correspondingly up and down.

[0035]Specifically, the first piston 3 and the cylinder 1 form a fuel compression chamber 2, and the top of the cylinder 1 is provided with an air inlet 18 corresponding to the fuel compression chamber 2; in a specific implementation, the air inlet 18 is provided with an intake check valve 19, and a fuel intake booster system is arranged corresponding to the intake port 18. The fuel intake booster system communicates with the intake port 18 through a fuel delivery pipe, and the fuel intake booster The system pressurizes fuel such as gasoline mixed with air, and presses it int...

Embodiment 3

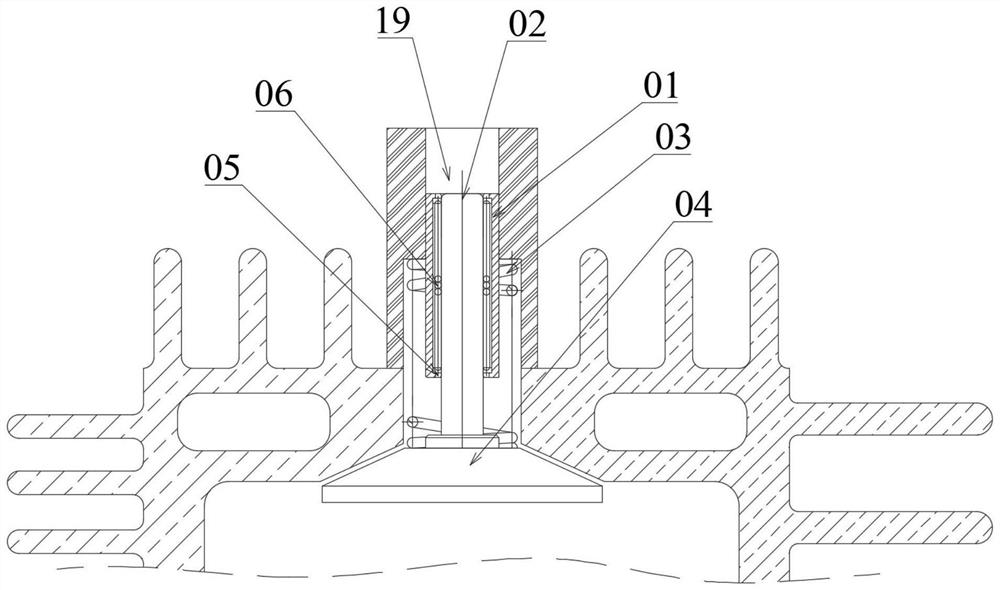

[0042] refer to figure 1 , figure 2 or image 3 , in this embodiment, it has the same engine body structure as Embodiment 1 and Embodiment 2; an air intake check valve 19 is arranged in the air intake port 18; the air intake check valve 19 includes an air intake port The supporting sleeve 01 fixedly arranged in 18, the supporting connecting rod 02 is set in the supporting sleeve 01 through the supporting ball 06, and the supporting connecting rod can move up and down easily relative to the supporting sleeve through the supporting ball; the supporting connecting rod 02 The other end is provided with a first valve plate 04 that blocks the fuel channel 301, and the support sleeve 01 is covered with a support spring 03 that is pressed into the first valve plate 04 and the air inlet 18; in this embodiment, The intake check valve 19 is opened downward, and the intake check valve 19 adopts a passive control valve. In this embodiment, the first valve plate 04 adopts a tapered struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com