Pump-free self-compression organic Rankine cycle engine

A Rankine cycle and engine technology, applied in the field of medium and low-grade energy utilization, can solve the problems of low efficiency of the working fluid pump, inability to work continuously, affecting the performance improvement of the organic Rankine cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

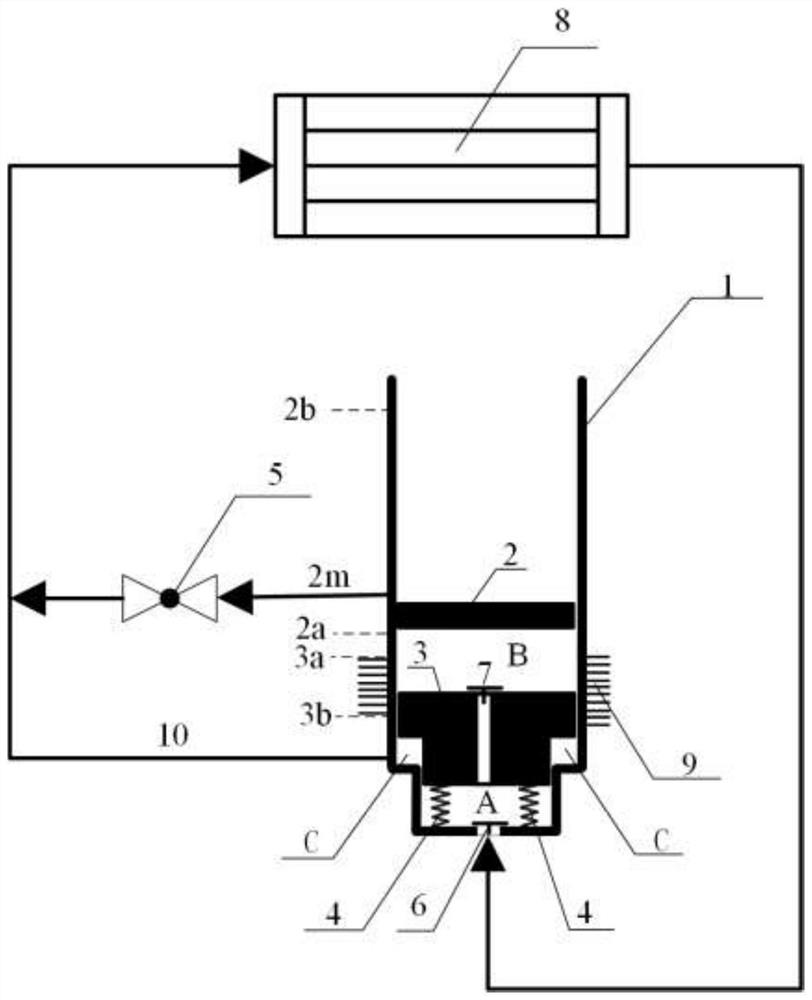

[0012] like figure 1 In the non-equal diameter cylindrical cylinder (1) shown, a main piston (2) and an auxiliary piston (3) are installed. The main piston (2) reciprocates between the first top dead center (2a) and the first bottom dead center (2b), and there is an exhaust outlet point (2m) in the middle near the top dead center; the auxiliary piston (3 ) is a non-equal-diameter T-shaped structure, and its small diameter part fits with the small diameter part of the bottom of the cylinder, and reciprocates between the second top dead center (3a) and the second bottom dead center (3b), and the second top dead center A heater (9) is installed on the cylinder between (3a) and the second bottom dead center (3b), which is used to heat the working medium in the cylinder to realize the conversion of thermal energy into mechanical energy. The main piston (2) is connected with the connecting rod, the crankshaft, etc., and converts reciprocating motion into rotary motion to realize me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com