Lithium-free cathode lithium battery system and electrode in-situ lithium nitride film preparation method

A lithium cathode and lithium battery technology, applied in the field of materials, can solve problems such as explosion, battery thermal runaway, and sharp decline in research and development interest in lithium-free cathodes, and achieve a wide range of choices and practical effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

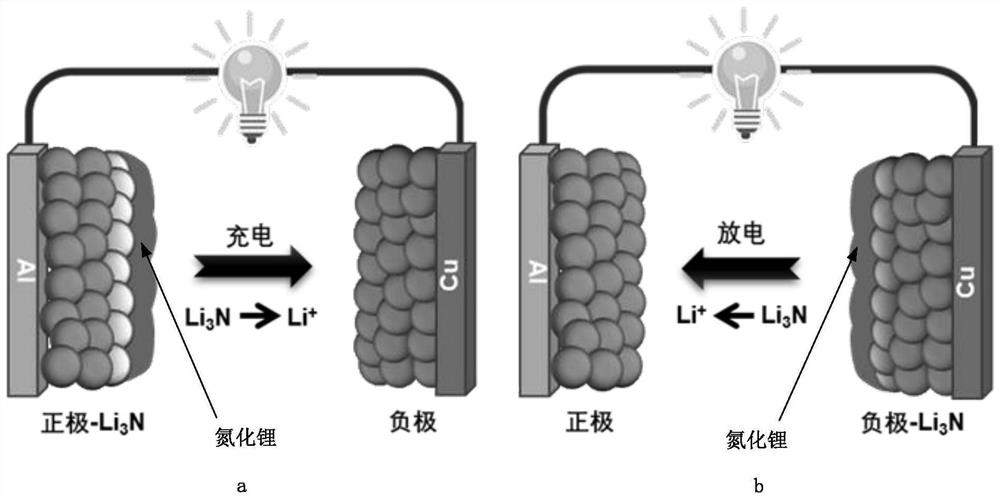

[0036] By adopting the preparation method provided by the invention, the positive electrode or the negative electrode used in the lithium battery system without lithium positive electrode can be prepared.

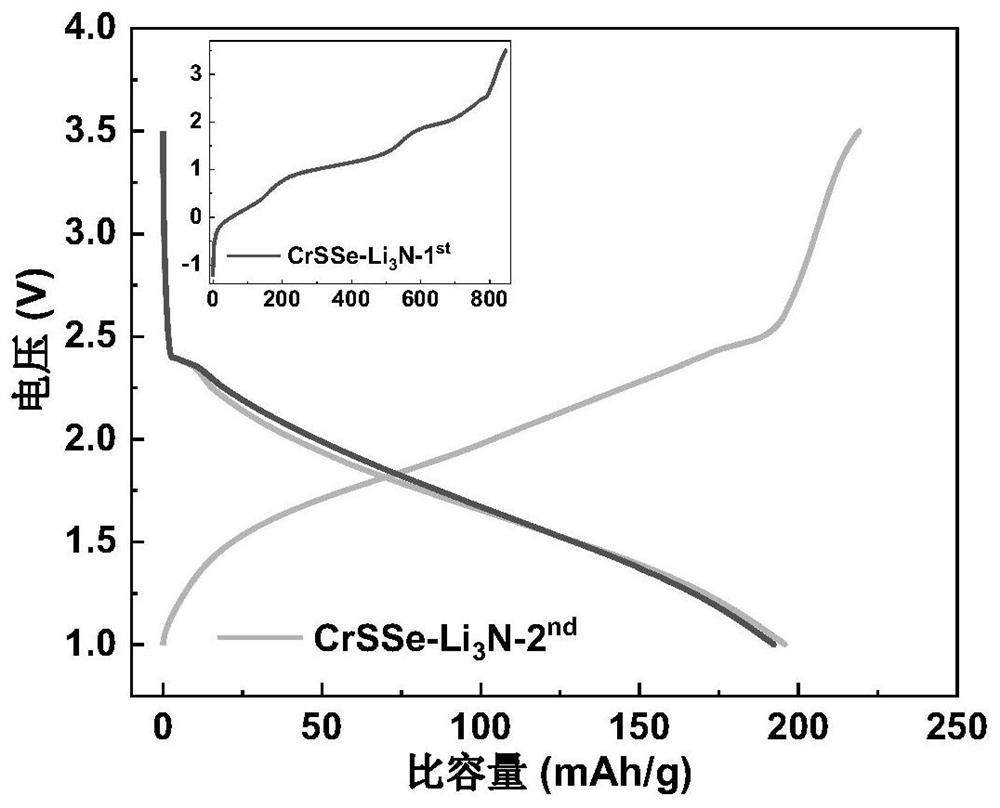

[0037] In order to better understand the technical solution provided by the present invention, the following uses a number of specific examples to illustrate the application of the methods provided in the above-mentioned embodiments of the present invention for the preparation and construction of electrode in-situ lithium nitride thin films in lithium-free cathode lithium battery systems. Characterization of lithium battery systems with lithium-free cathodes.

Embodiment 1

[0039] This embodiment provides a method for constructing a novel lithium-ion battery system without a lithium positive electrode, comprising the following steps:

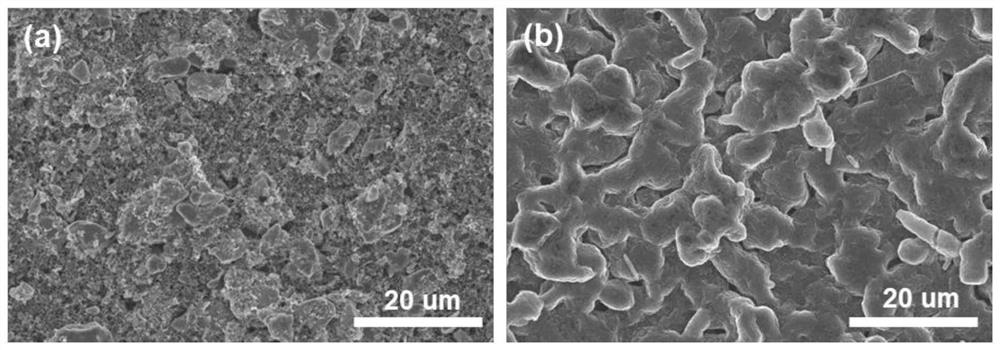

[0040] Disperse the positive electrode material chromium sulfur selenium CrSSe, conductive carbon black (Super P), and polyvinylidene fluoride (PVDF) in nitrogen methyl pyrrolidone (NMP) at a mass ratio of 8:1:1, homogenize and coat on aluminum foil , made into anode sheet after drying and rolling.

[0041] Disperse the negative electrode material soft carbon (SC), conductive carbon black (Super P), and polyvinylidene fluoride (PVDF) in nitrogen methyl pyrrolidone (NMP) at a mass ratio of 92:3:5, and coat it on copper after homogenizing. On the foil, the negative electrode sheet is made after drying and rolling, and the positive and negative electrode unit surface capacity ratio is 1:1.1.

[0042] Lithium metal is evaporated on the surface of the positive electrode by vacuum thermal evaporation. The prepared posi...

Embodiment 2

[0048] This embodiment provides a method for constructing a novel lithium-ion battery system without a lithium positive electrode, comprising the following steps:

[0049] The positive electrode material titanium disulfide TiS 2 , conductive carbon black (Super P), and polyvinylidene fluoride (PVDF) are dispersed in nitrogen methyl pyrrolidone (NMP) at a mass ratio of 8:1:1, homogenized and coated on aluminum foil, and dried and rolled Make a positive electrode sheet.

[0050] Negative electrode material graphite, conductive carbon black (Super P), and polyvinylidene fluoride (PVDF) were dispersed in nitrogen-methylpyrrolidone (NMP) at a mass ratio of 92:3:5, homogenized and coated on copper foil. After drying and rolling, the negative electrode sheet is made, and the positive and negative electrode unit surface capacity ratio is 1:1.1.

[0051] Lithium metal is evaporated on the surface of the positive electrode by vacuum thermal evaporation. The prepared positive pole pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com