Organic lithium-philic composite negative electrode taking three-dimensional conductive carbon material as substrate and preparation method of organic lithium-philic composite negative electrode

A technology of conductive carbon and carbon materials, which is applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of low lithium storage capacity, reduced current density, and complicated preparation process of lithium deposition substrate materials, so as to improve cycle stability and inhibit Dendrite growth, the effect of improving the volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

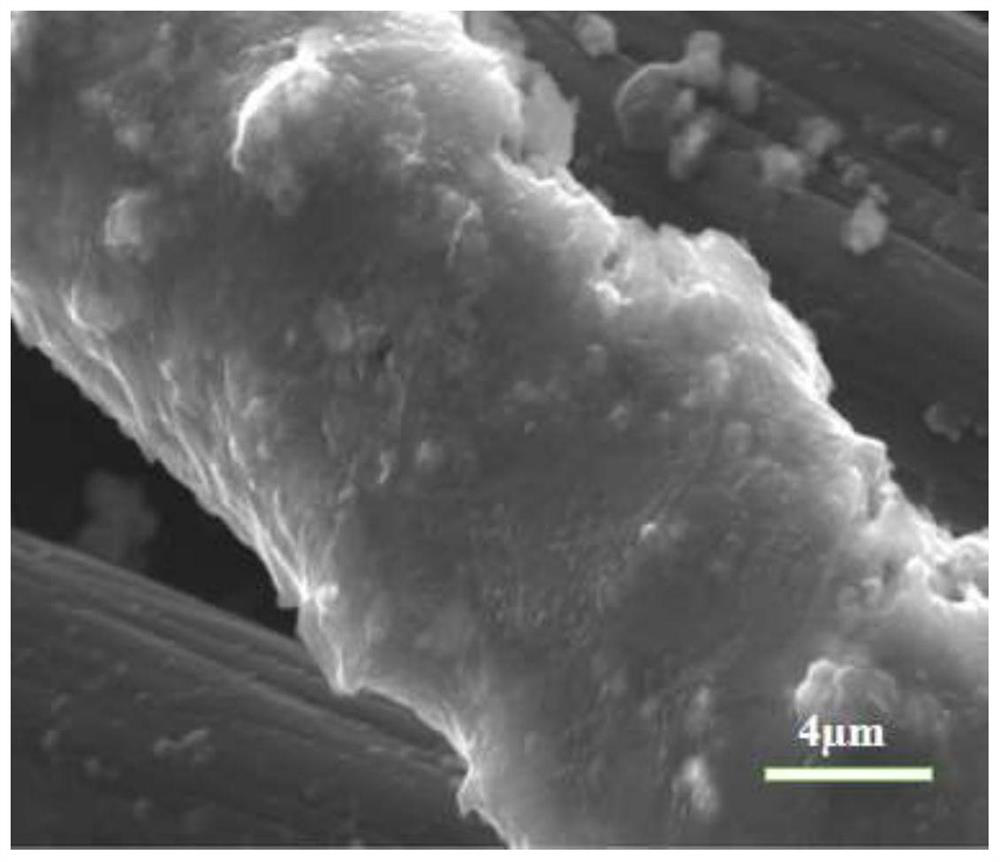

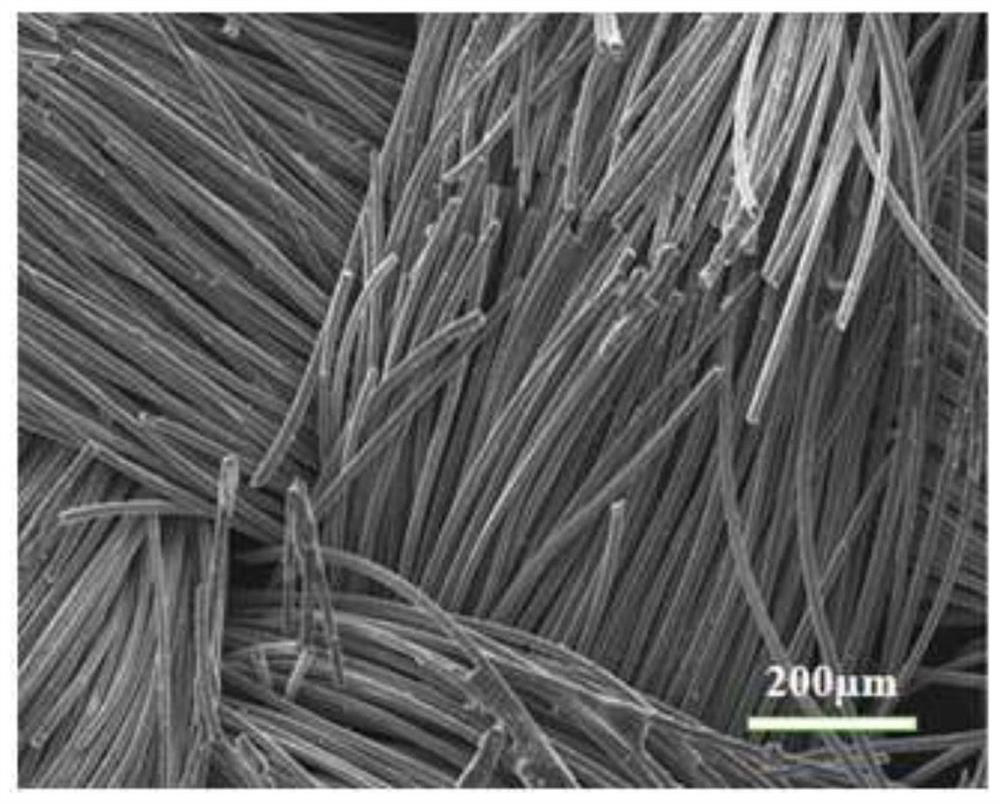

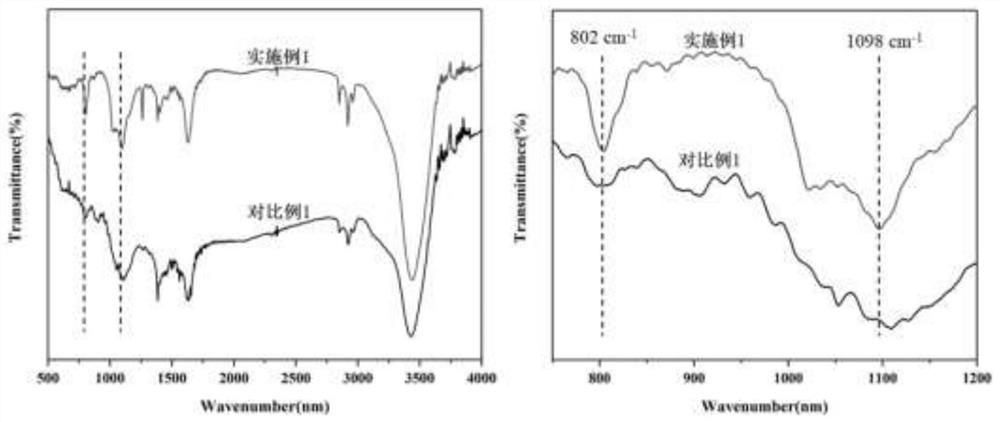

[0037] An organic lithiophilic layer based on a three-dimensional conductive carbon fiber cloth is prepared by a hydrothermal method and a high-temperature molten lithium deposition method to prepare a lithiophilic composite negative electrode, comprising the following preparation steps:

[0038] 1) Cut the three-dimensional conductive carbon fiber cloth into discs with a pore size of 8 mm, put them into an ultrasonic cleaner, and wash them alternately with ethanol and deionized water for 3 times, each time for 10 minutes, to remove impurities on the surface; prepare 30 mL of 40wt% nitric acid solution, then add 5mL concentrated sulfuric acid (98wt%), soak the three-dimensional conductive carbon fiber cloth in it for 30min, then place it in the reaction kettle, put it into the blast drying oven for 10h at 120°C for hydrothermal treatment, and The surface is oxidized and modified; finally, it is alternately washed 3 times with deionized water and ethanol to remove the residual a...

Embodiment 2

[0048] An organic lithiophilic layer based on a three-dimensional conductive carbon fiber cloth is prepared by a hydrothermal method and a high-temperature molten lithium deposition method to prepare a lithiophilic composite negative electrode, comprising the following preparation steps:

[0049] 1) Cut the three-dimensional conductive carbon fiber cloth into discs with a pore size of 8 mm, put them into an ultrasonic cleaner, and wash them alternately with ethanol and deionized water for 3 times, each time for 10 minutes, to remove impurities on the surface; prepare 30 mL of 30wt% nitric acid solution, then add 5mL of concentrated sulfuric acid (98wt%), soak the three-dimensional conductive carbon fiber cloth in it and ultrasonic for 30min, then place it in the reaction kettle, put it into the blast drying oven for 12h at 100°C for hydrothermal treatment, and The surface is oxidized and modified. Finally, alternately wash three times with deionized water and ethanol to remove...

Embodiment 3

[0053] An organic lithiophilic layer based on a three-dimensional conductive carbon fiber cloth is prepared by a hydrothermal method and a high-temperature molten lithium deposition method to prepare a lithiophilic composite negative electrode, comprising the following preparation steps:

[0054] 1) Cut the three-dimensional conductive carbon fiber cloth into a disc with a pore size of 10 mm, put it into an ultrasonic cleaner and wash it with ethanol and deionized water alternately for 3 times, each time for 10 minutes, to remove impurities on the surface; prepare 30 mL of 50wt% nitric acid solution, then add 5mL of concentrated sulfuric acid (98wt%), soak the three-dimensional conductive carbon fiber cloth in it and ultrasonic for 30min, then place it in the reaction kettle, put it into the blast drying oven for 8h at 100°C for hydrothermal treatment, and The surface is oxidized and modified; finally, it is alternately washed 3 times with deionized water and ethanol to remove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com