Mung bean paste sandwich bread and preparation method thereof,

A sandwich bread and mung bean technology, which is applied in dough preparation, pre-baked dough treatment, baking, etc., can solve the problem of no sandwich bread, etc., and achieve the effect of rich variety, good development prospects, and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A mung bean bean paste sandwich bread, the components and parts by weight of the sandwich bread are: 100g of high-gluten flour, 1.5g of instant active yeast, 15g of white soft sugar, 20g of milk, 32g of water, 10g of eggs, 0.5g of salt, Corn oil 1g, mung bean bean paste 15g.

[0048] Process flow:

[0049] Production of mung bean bean paste→dough preparation→fermentation→cutting and rounding→proofing in the middle→forming→proofing→baking→cooling→finished product→tasting and sensory evaluation.

[0050] A kind of preparation method of mung bean bean paste sandwich bread comprises the steps:

[0051] 1) According to the preparation of a kind of mung bean bean paste sandwich bread;

[0052] 2) Mung bean bean paste production:

[0053] a selection of raw materials, cleaning, soaking

[0054] Select mung beans with full grains, no bad grains, uniform size and color, and bright surface, and remove visible impurities, wash with clean water first, and soak for 12 hours acco...

Embodiment 2

[0067] Single factor experiment of mung bean bean paste sandwich bread

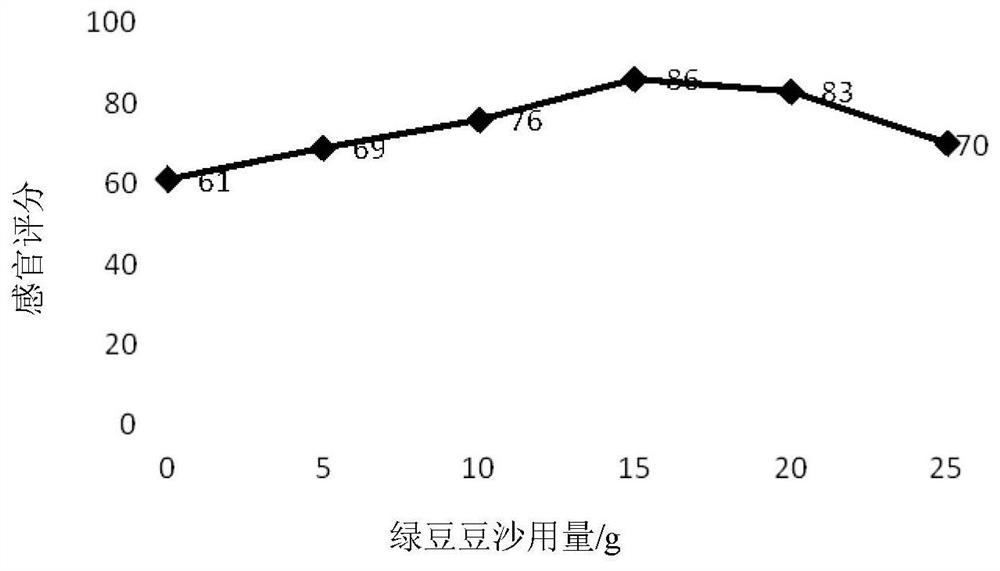

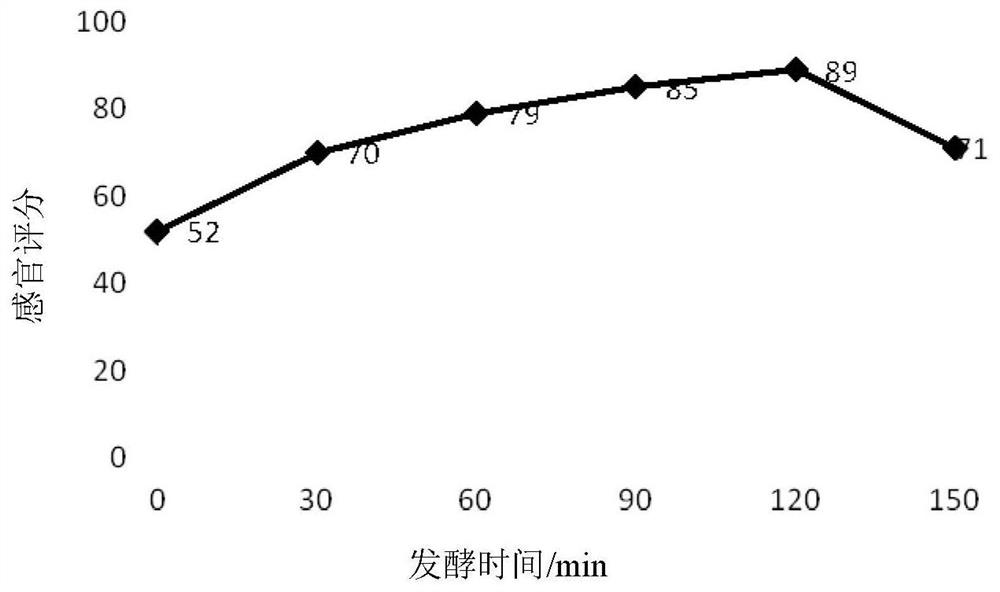

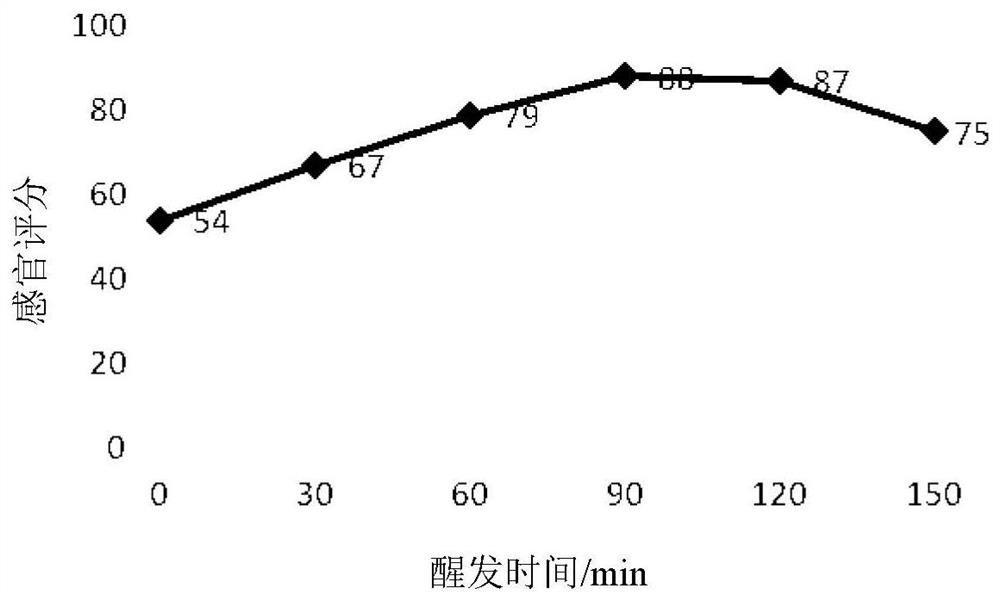

[0068] On the basis of the basic formula, the dosage of mung bean paste is 0, 5, 10, 15, 20, 25; , 150min as a single factor, to study the influence of three factors on the quality of mung bean bean paste sandwich bread. See Example 6 for the sensory evaluation method.

[0069] For the sensory evaluation of bread with different amounts of mung bean and bean paste, see figure 1 , Conclusion: Mung bean bean paste has the characteristics of clearing heat and detoxifying, sweet taste, soft and glutinous texture, and sandy texture. It is a kind of filling that consumers generally like. The test results show that the mung bean bean paste sandwich bread with mung bean bean paste added with 15%-20% has the aroma of mung bean bean paste, and when you break it from the middle, you can see the light green bean paste color, the taste is soft and waxy with a sandy texture, and the sensory score is higher, 83 -89 po...

Embodiment 3

[0073] Orthogonal experiment of sandwich bread with mung bean paste

[0074] Through the preliminary test, mung bean bean paste, fermentation time, and proofing time have a great influence on the quality of bread. Therefore, the amount of mung bean bean paste, fermentation time, and proofing time are selected as three factors and three levels for orthogonal experiments, as shown in Table 1. See Example 6 for the sensory evaluation method.

[0075] Table 1

[0076]

[0077] Best Bread Recipe L 9 (3 3 ) Orthogonal test range analysis results are shown in Table 2

[0078] Table 2

[0079]

[0080] Conclusion: It can be seen from Table 2 that the magnitude of the extreme difference R is C>B>A, which shows that the bread proofing time is the main factor affecting the quality of the bread, followed by the dough fermentation time, and finally the amount of mung bean bean paste . Therefore, under the conditions of this experiment, the optimal combination of mung bean bean ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com