Low-viscosity drinking yoghourt and preparation method thereof

A drinking-type, low-viscosity technology, which is applied in the field of low-viscosity drinking-type yoghurt and its preparation, can solve the problems of not refreshing enough, sticky taste, etc., and achieve the effects of refreshing taste, reducing satiety, and lightening the nutritional needs of sports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

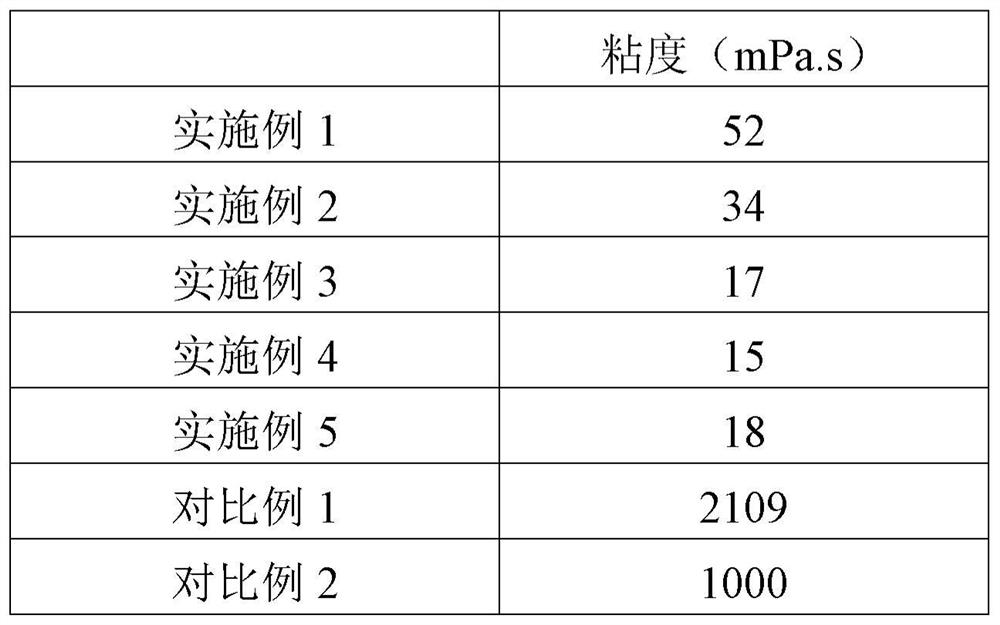

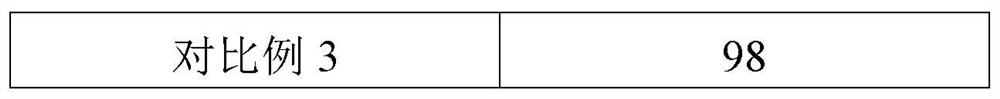

Examples

Embodiment 1

[0032] 1. Raw material formula

[0033] Yogurt base (1 ton): 12kg of concentrated milk protein, 80kg of white sugar, 10kg of cream, 100g of Streptococcus thermophilus, 200g of Lactobacillus bulgaricus, 20g of Bifidobacterium, 20g of Lactobacillus rhamnosus, and the rest milk Up to 1000kg; sugar solution base material (calculated in 1 ton): white granulated sugar 90kg, BETA pectin 4kg, essence 0.5kg, and the remaining water to make up to 1000kg.

[0034] Preparation

[0035] 1. Prepare the yogurt base: heat the raw milk to 60°C, put sugar, concentrated milk protein, and cream into the milk and stir for 30 minutes, homogenize at 20MP, then sterilize at 90°C for 15 minutes, and cool down to 43°C. Inoculate the starter into the cooled raw milk, ferment at 43°C until the titrated acidity reaches 90°T, stop the fermentation, quickly break the emulsion and cool down to 20°C.

[0036] 2. Preparation of Sugar Liquid Base

[0037] Raise the temperature of pure water to 30°C, put the ...

Embodiment 2

[0042] 1. Raw material formula

[0043] Yogurt base material (1 ton): 20kg of concentrated milk protein, 60kg of white sugar, 30kg of cream, 200g of Streptococcus thermophilus, 200g of Lactobacillus bulgaricus, 10g of Bifidobacterium, 10g of Lactobacillus rhamnosus, and the rest milk Up to 1000kg; sugar liquid base material (1 ton): 50kg white sugar, 30kg glucose, 2kg BETA pectin, 0.6kg potassium chloride, 0.6kg sodium chloride, 0.3kg essence, and make up the rest to 1000kg with water .

[0044] Preparation

[0045] 1. Prepare the yogurt base: heat the raw milk to 50°C, put sugar, concentrated milk protein, and cream into the milk and stir for 20 minutes, homogenize at 18MP, then sterilize at 92°C for 10 minutes, and cool down to 40°C. Inoculate the starter into the cooled raw milk, ferment at 40°C until the titrated acidity reaches 80°T, stop the fermentation, rapidly demulsify and cool down to 15°C.

[0046] 2. Preparation of Sugar Liquid Base

[0047] Raise the temperat...

Embodiment 3

[0052] 1. Raw material formula

[0053] Yogurt base (1 ton): 12kg concentrated milk protein, 70kg white sugar, 10kg cream, 300g lactase, 100g Streptococcus thermophilus, 100g Lactobacillus bulgaricus, 200g Bifidobacterium, 100g Lactobacillus rhamnosus, Make up the remaining amount of milk to 1000kg; smoothie base material (1 ton): 50kg of white sugar, 400kg of sweet orange juice, 3kg of BETA pectin, and make up the remaining amount of water to 1000kg.

[0054] Preparation

[0055] 1. Prepare the yogurt base: heat the raw milk to 45°C, put sugar, concentrated milk protein, and cream into the milk and stir for 25 minutes, homogenize at 18MP, then sterilize at 90°C for 10 minutes, and cool down to 42°C. Inoculate the starter into the cooled raw milk, ferment at 40°C until the titrated acidity reaches 80°T, stop the fermentation, rapidly demulsify and cool down to 15°C.

[0056] 2. Preparation of Smoothie Base

[0057] Raise the temperature of pure water to 40°C, put the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com