Processed cheese and preparation method thereof

A technology of processed cheese and natural cheese, which is applied in the field of food processing, can solve the problems of diarrhea and allergies, single flavor, poor health care effect, etc., and achieve the effect of fine texture, smooth appearance and excellent taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

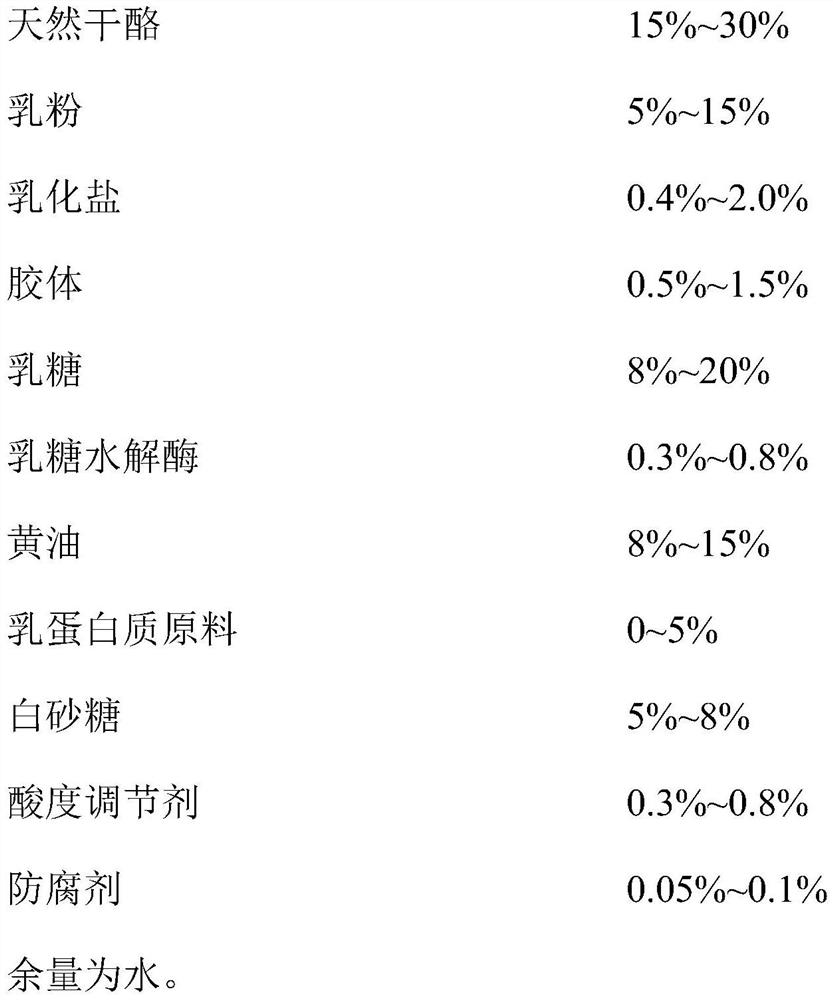

[0070] This embodiment prepares a kind of processed cheese, and described processed cheese comprises by mass percentage:

[0071] Cheddar Cheese 10%, Cream Cheese 10%, Butter 10%, Skim Milk Powder 5%, Concentrated Milk Protein 4%, White Sugar 6%, Lactose 10%, Gelatin 0.1%, Carrageenan 0.3%, Locust Bean Gum 0.1% , sodium citrate 0.5%, compound phosphate 0.5%, lactose hydrolase 0.3%, lactic acid 0.3%, potassium sorbate 0.05%, and the balance is water.

[0072] The preparation method of the processed cheese comprises the following steps:

[0073] (1) Cheddar cheese, cream cheese, butter, skimmed milk powder and concentrated milk protein were mixed with water and mixed for 8 minutes at a speed of 500 rpm to obtain a chopped mixture;

[0074] (2) Add lactose, white granulated sugar, sodium citrate, compound phosphate, gelatin, carrageenan, locust bean gum and potassium sorbate in the chopped mixture of step (1), under 500rpm rotating speed, 40 ℃ Heat and mix at low temperature, a...

Embodiment 2

[0078] This embodiment prepares a kind of processed cheese, and described processed cheese comprises by mass percentage:

[0079] Cheddar Cheese 15%, Cream Cheese 10%, Butter 8%, Skim Milk Powder 6%, Concentrated Milk Protein 5%, White Sugar 8%, Lactose 8%, Gelatin 0.4%, Xanthan Gum 0.1%, Carrageenan 0.5% , locust bean gum 0.5%, sodium citrate 0.4%, lactose hydrolase 0.8%, lactic acid 0.8%, sorbic acid 0.1%, and the balance is water.

[0080] The preparation method of the processed cheese comprises the following steps:

[0081] (1) Cheddar cheese, cream cheese, butter, skimmed milk powder and concentrated milk protein were mixed with water and mixed for 5 minutes at a speed of 1000 rpm to obtain a chopped mixture;

[0082] (2) Add lactose, white granulated sugar, sodium citrate, gelatin, xanthan gum, carrageenan, locust bean gum and sorbic acid to the chopping mixture in step (1), at a temperature of 45° C. at 1000 rpm Heat and mix, and add lactose hydrolase to continue stir...

Embodiment 3

[0086] This embodiment prepares a kind of processed cheese, and described processed cheese comprises by mass percentage:

[0087] Cheddar Cheese 20%, Cream Cheese 10%, Butter 15%, Skim Milk Powder 15%, Concentrated Milk Protein 4%, White Sugar 5%, Lactose 10%, Gelatin 0.4%, Xanthan Gum 0.1%, Carrageenan 0.2% , locust bean gum 0.4%, sodium citrate 2%, lactose hydrolase 0.3%, lactic acid 0.6%, sorbic acid 0.05%, potassium sorbate 0.05%, and the balance is water.

[0088] The preparation method of the processed cheese comprises the following steps:

[0089] (1) Cheddar cheese, cream cheese, butter, skimmed milk powder and concentrated milk protein were mixed with water and mixed for 4 minutes at a speed of 1000 rpm to obtain a chopped mixture;

[0090] (2) Add lactose, white granulated sugar, sodium citrate, gelatin, xanthan gum, carrageenan, locust bean gum, sorbic acid and potassium sorbate in the chopped mixture of step (1), under 1500rpm rotating speed, 40 Heat and mix at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Probe diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com