Blasting bead for cigarettes and preparation method

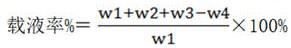

A technology for smoking and popping beads, which is applied in the fields of tobacco, application, and treatment of tobacco. It can solve the problems of high viscosity of the adhesive layer solution, low liquid loading rate, and thicker wall materials, so as to improve product quality and stability. The effect of high liquid loading rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A popping bead for cigarettes, which is composed of a wall material and a core material, the weight percentage of the wall material is 5-20%, and the weight percentage of the core material is 80-95%.

[0046] Specifically, the wall material is an amphiphilic photocurable resin with a block structure; the core material is an aqueous essence solution containing a photosensitizer, wherein the photosensitizer is water-soluble and has a mass percent concentration of 0.01-0.1 %.

Embodiment 2

[0048]The amphiphilic photocurable resin is selected from any one or more of epoxy acrylate, polyurethane acrylic resin, polyester acrylic resin, and aminoacrylic resin. Strength, wall material thickness, etc. determine how to compound the amphiphilic photocurable resin.

[0049] Photosensitizers include natural photosensitizers such as curcumin, riboflavin, quinone compounds and psoralen, porphyrin compounds, cationic porphyrin compounds, bacterial chlorophyll derivatives, phthalocyanine and its derivatives, methylene blue And phenothiazine compounds, tetraiodofluorescein, and other commercially available water-soluble photosensitizer products, etc.

Embodiment 3

[0051] A method for preparing popping beads for cigarettes, the method comprising the following steps:

[0052] The wall material is dissolved in an organic solvent, and the weakly polar organic solvent is used as a dispersant for the photocurable resin, and the photocurable resin is dispersed in it to form a forming liquid;

[0053] The core material is an aqueous essence solution, and a small amount of water-soluble photosensitizer is added to initiate the crosslinking and curing of the resin; the core material is dropped into the forming liquid with a dropper, and the water droplet remains spherical because water is incompatible with the organic solvent of the forming liquid. The amphiphilic photocurable resin dispersed in the forming liquid, driven by thermodynamic force, gathers at the interface between water droplets and organic solvents, and self-assembles to form a wrapped core due to interfacial tension and the interaction between molecular segments. the spherical sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com