A kind of preparation method of SMCO perpendicular magnetic anisotropy film

An anisotropic, magnetic thin film technology, applied in the application of magnetic film to substrate, vacuum evaporation coating, coating, etc., can solve the film grain growth product performance, unfavorable efficient and accurate preparation, film forming factors Many other problems, to avoid excessive grain growth, improve magnetic properties, and shorten the processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

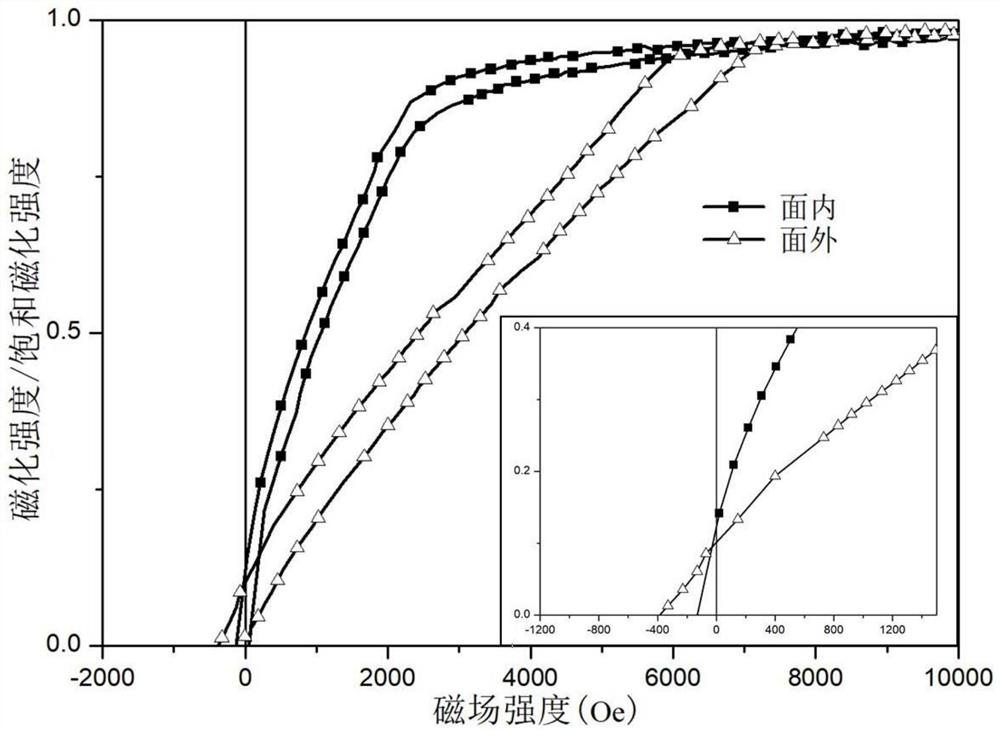

Embodiment 1

[0039] A kind of SmCo perpendicular magnetic anisotropy film, its preparation method comprises the following steps:

[0040] 1) A magnetic thin film of Cr(20nm) / Cu(40nm) / SmCo(200nm) / Cr(20nm) structure was prepared by a magnetron sputtering system in an argon environment, and the substrate was a single crystal Si(100) substrate, The size is 10mm×10mm, the purity is 99.9%, and it is ultrasonically cleaned with 5% hydrofluoric acid, acetone and absolute ethanol before use. The background vacuum of the magnetron sputtering system is 8×10 -5 ~1×10 -4 Pa, the working pressure of argon during the sputtering process is kept at 0.5Pa, the vertical distance between the target and the single crystal Si(100) substrate is controlled at 6cm, the Cu target and the SmCo (Sm:Co=1:4) alloy target are used DC sputtering, sputtering power is 60W, Cr target adopts radio frequency sputtering, sputtering power is 120W;

[0041] 2) Put the magnetic film in step 1) into an infrared annealing furnace...

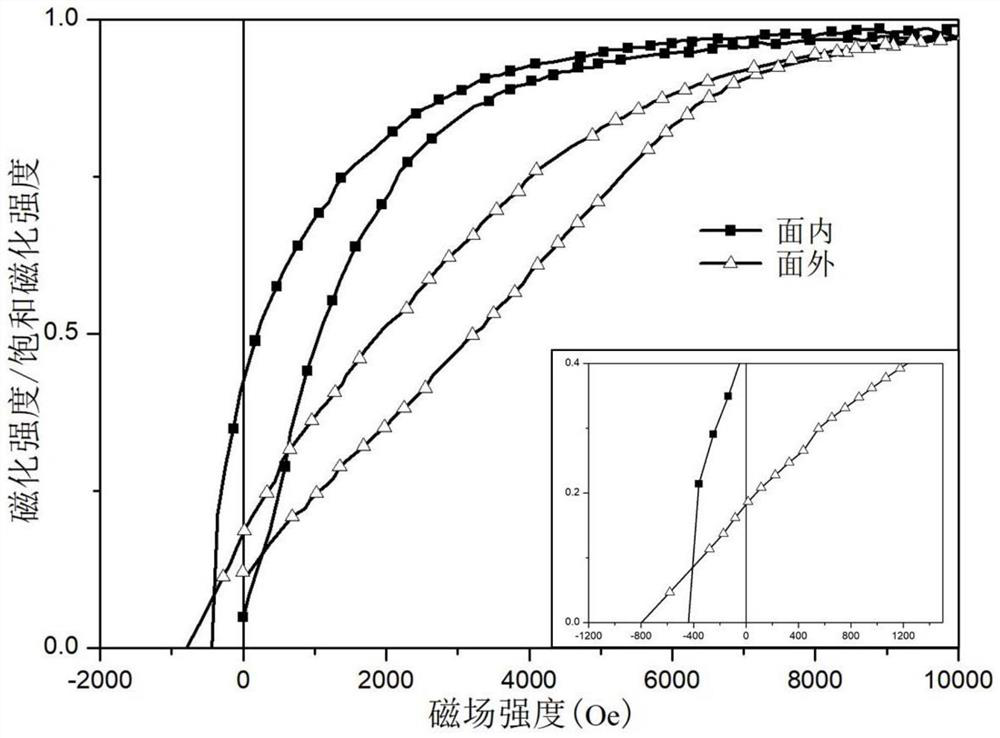

Embodiment 2

[0045] A kind of SmCo perpendicular magnetic anisotropy film, its preparation method comprises the following steps:

[0046]1) A magnetic thin film of Cr(20nm) / Cu(40nm) / SmCo(200nm) / Cr(20nm) structure was prepared by a magnetron sputtering system in an argon environment, and the substrate was a single crystal Si(100) substrate, The size is 10mm×10mm, the purity is 99.9%, and it is ultrasonically cleaned with 5% hydrofluoric acid, acetone and absolute ethanol before use. The background vacuum of the magnetron sputtering system is 8×10 -5 ~1×10 -4 Pa, the working pressure of argon during the sputtering process is kept at 0.5Pa, the vertical distance between the target and the single crystal Si(100) substrate is controlled at 6cm, the Cu target and the SmCo (Sm:Co=1:4) alloy target are used DC sputtering, sputtering power is 60W, Cr target adopts radio frequency sputtering, sputtering power is 120W;

[0047] 2) Put the magnetic film in step 1) into an infrared annealing furnace,...

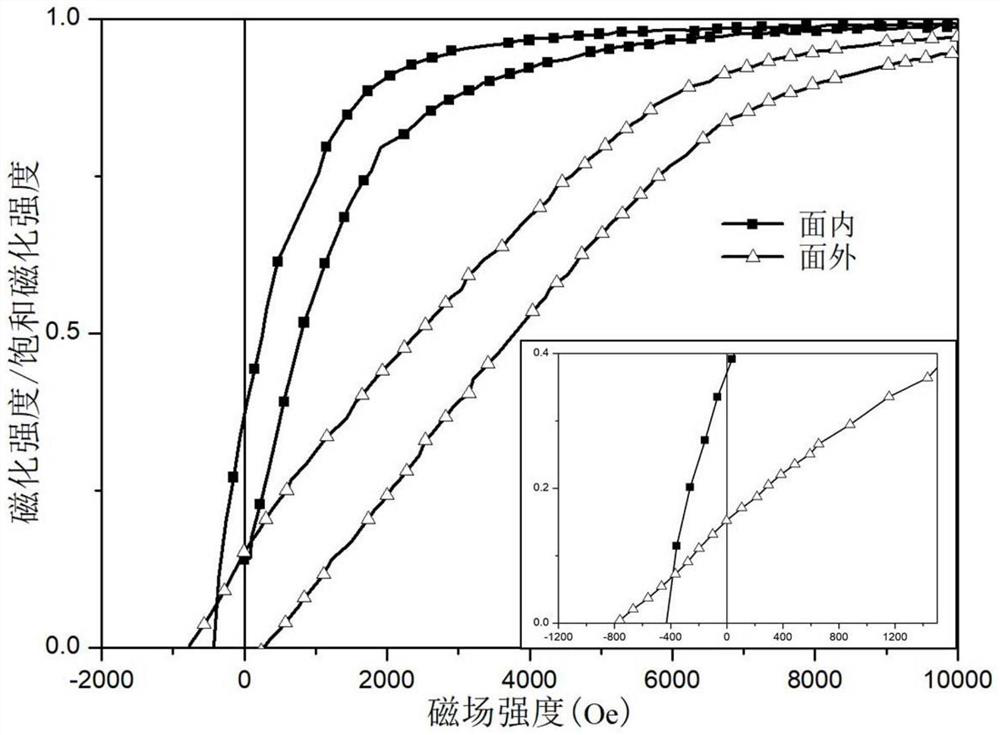

Embodiment 3

[0051] A kind of SmCo perpendicular magnetic anisotropy film, its preparation method comprises the following steps:

[0052] 1) A magnetic thin film of Cr(20nm) / Cu(40nm) / SmCo(200nm) / Cr(20nm) structure was prepared by a magnetron sputtering system in an argon environment, and the substrate was a single crystal Si(100) substrate, The size is 10mm×10mm, the purity is 99.9%, and it is ultrasonically cleaned with 5% hydrofluoric acid, acetone and absolute ethanol before use. The background vacuum of the magnetron sputtering system is 8×10 -5 ~1×10 -4 Pa, the working pressure of argon during the sputtering process is kept at 0.5Pa, the vertical distance between the target and the single crystal Si(100) substrate is controlled at 6cm, the Cu target and the SmCo (Sm:Co=1:4) alloy target are used DC sputtering, sputtering power is 60W, Cr target adopts radio frequency sputtering, sputtering power is 120W;

[0053] 2) Put the magnetic film in step 1) into an infrared annealing furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com