Device for optimizing quality of high-power laser beam, testing device and preparation method

A laser beam quality and high power technology, applied in the laser field, can solve problems such as poor beam quality, achieve the effects of reducing area, improving nonlinearity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

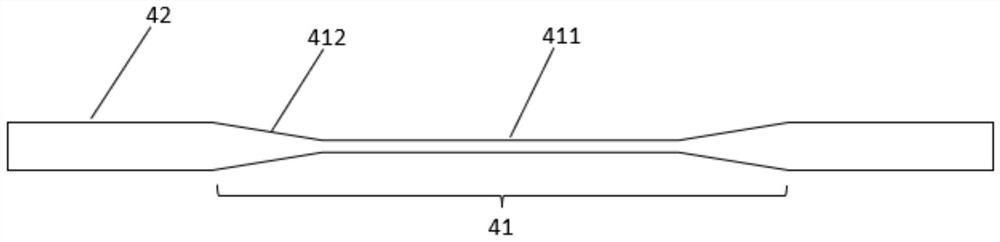

[0027] like figure 1 As shown, the present invention provides a device for optimizing the quality of high-power laser beams, which is formed by melting and tapering a graded-index multimode fiber to form a structure with a thin middle and thick ends, and the two sides are still graded-index multimode fibers; After the graded-index multimode optical fiber is fused and tapered, the heated area will form a tapered region 41 , including a waist region 411 and a transition region 412 . Wherein, the diameter of the girdle region 411 is 10 microns, and the transition region 412 is between the girdle region 41 and the region 42 of the non-melted tapered tapered region. graded-index multimode fiber.

[0028] In this embodiment, the core diameter of the graded-index multimode optical fiber is 62.5 microns, and the cladding diameter is 125 microns.

[0029] The tapered graded-index optical fiber has a waist diameter of 10 microns, a tapered length of 5.0 cm, a total fiber length of 1 m...

Embodiment 2

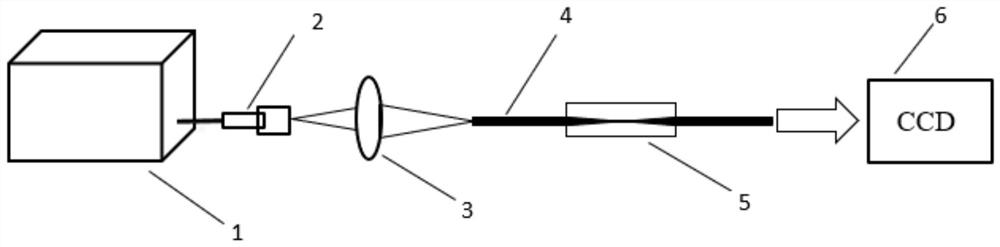

[0031] like figure 2 Shown, the present invention also provides a kind of testing device for high-power laser beam quality optimization device, comprises the graded-index multimode optical fiber of high-power laser 1, collimator 2, focusing lens 3, melting taper (for High-power laser beam quality optimization device) 4, glass slide 5 and CCD camera 6;

[0032] The output light of the high-power laser 1 is coupled into the graded-index multimode fiber (for high-power laser beam quality optimization device) 4 fixed on the glass slide 5 through the collimator 2 and the focusing lens 3, The light spot is recorded with a CCD camera 6 at the output end of the fiber.

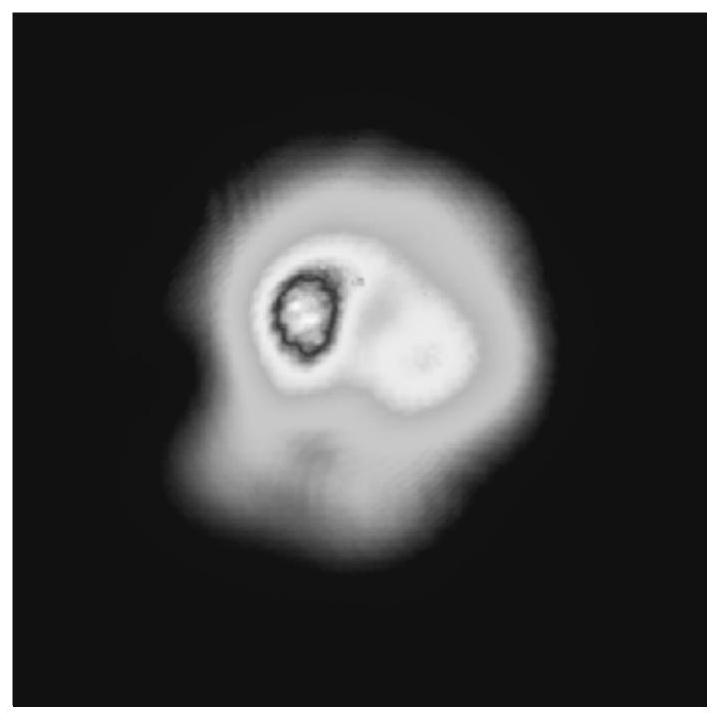

[0033] image 3 is the stray light spot before entering the fused tapered graded-index multimode fiber, Figure 4 For the clean spot after passing through the graded-index multimode fiber with fused taper, Figure 5 It is the light spot output by the high-power laser passing through the graded-index multimode fibe...

Embodiment 3

[0035] The present invention also provides a preparation method for high-power laser beam quality optimization device, comprising the following steps:

[0036] (1) Peel off the coating layer on the central part of the graded-index multimode fiber, and wipe it clean with alcohol;

[0037] (2) Under the action of the alcohol lamp, the central part of the optical fiber is tapered into a cone area with a minimum diameter of 10 microns by using the method of melting tapering, and the other areas remain unchanged;

[0038] (3) Fix the two ends of the tapered micro-nano fiber on the glass slide.

[0039] Due to the self-image effect of the graded-index multimode fiber, the laser beam enters the fiber and forms periodic light intensity modulation in the fiber core. The Kerr effect will cause periodic refractive index modulation in the fiber core, forming a structure similar to a long-period fiber grating, and there will be nonlinear energy coupling between different modes that meet t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com