Mineral microorganism cemented filling material capable of mineralizing and sealing CO2 and preparation method for mineral microorganism cemented filling material

A technology of microbial glue and filling materials, which is applied in the field of mine filling materials and microorganisms, can solve problems such as high energy consumption and high carbon emissions, and achieve the effects of reducing carbon emissions, reducing CO2 emissions, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

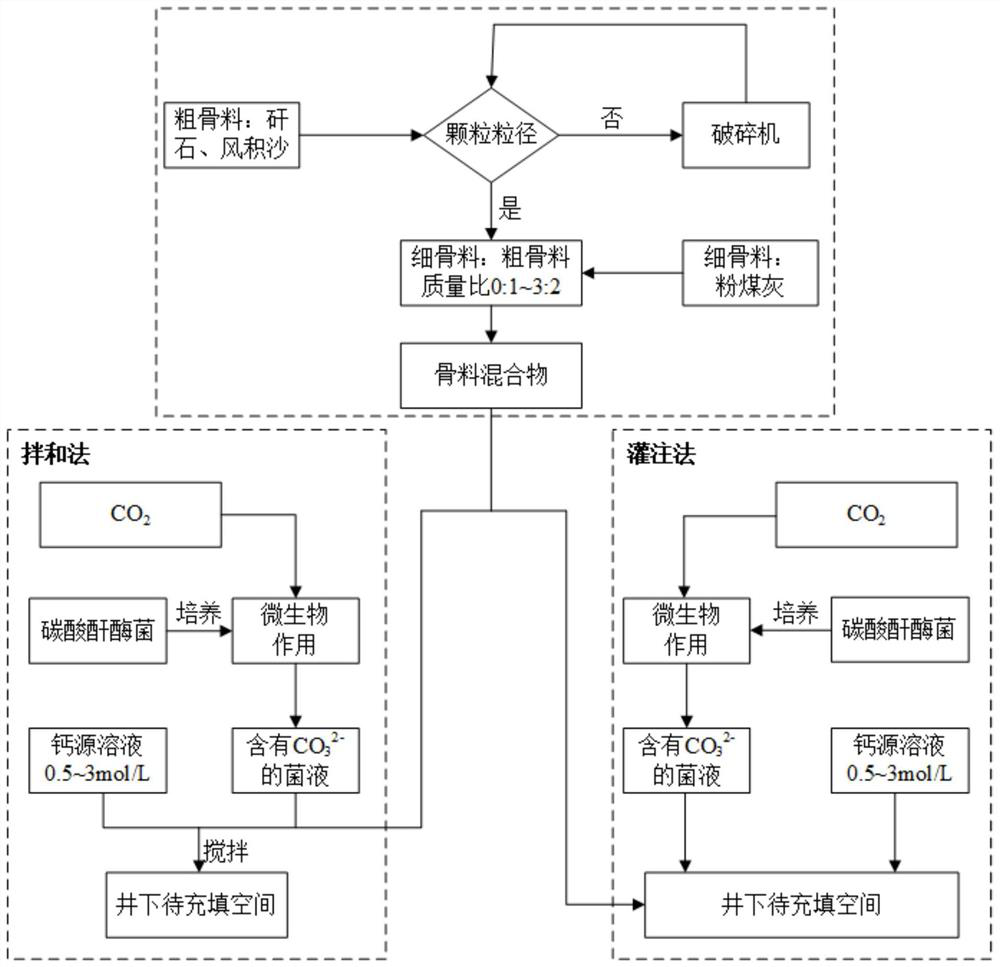

Method used

Image

Examples

Embodiment 1

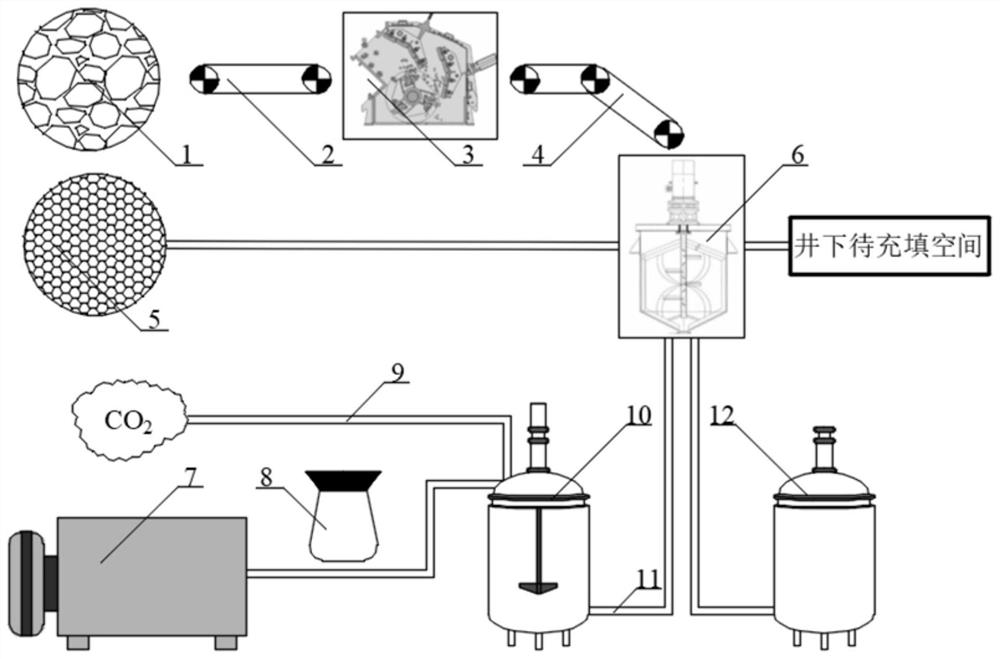

[0044] In this example, the mineralized and stored CO is prepared by the mixing method. 2 Microbial cemented filling materials for mines, such as figure 2 As shown, the specific steps are as follows:

[0045] (1) Inoculate the CA bacterium producing carbonic anhydrase in the culture medium, cultivate it in the incubator 7 for 18 hours at 25°C to obtain the seed solution 8, and then expand the culture to form the bacterium solution 10; and prepare a concentration of 2mol / L of calcium source solution 12;

[0046] (2) choose gangue as coarse aggregate 1, and select fly ash as fine aggregate 5; wherein, the mass ratio of fine aggregate to coarse aggregate is 3:2; coarse aggregate 1 is transported to the crusher through belt conveyor 2 3. Crushing until the particle size is less than or equal to 25mm, and then transported to the mixer 6 by the belt conveyor 4;

[0047] (3) Pass CO into the bacterial solution 2 Gas 9, formed containing CO 3 2- Bacteria solution 11; among the...

Embodiment 2

[0051] In this example, the mineralized and stored CO is prepared by the mixing method. 2 Microbial cemented filling materials for mines, such as figure 2 As shown, the specific steps are as follows:

[0052] (1) Inoculate the CA bacterium producing carbonic anhydrase in the medium, cultivate it in the incubator 7 for 12 hours at 37° C. to obtain the seed liquid 8, and then expand the culture to form the bacterial liquid 10; and prepare a concentration of 0.5 mol Calcium source solution 12 / L;

[0053] (2) Select tailing sand as coarse aggregate 1, and select fly ash as fine aggregate 5; wherein, the mass ratio of fine aggregate to coarse aggregate is 1:1; The machine 3 crushes the particles until the particle size is ≤25mm, and then transports them to the mixer 6 through the belt conveyor 4;

[0054] (3) Pass CO into the bacterial solution 2 Gas 9, formed containing CO 3 2- Bacteria solution 11; among them, containing CO 3 2- The volume ratio of the bacteria liquid an...

Embodiment 3

[0058] In this example, the mineralized and stored CO is prepared by the mixing method. 2 Microbial cemented filling materials for mines, such as figure 2 As shown, the specific steps are as follows:

[0059] (1) Inoculate the CA bacterium producing carbonic anhydrase in the culture medium, cultivate it in the incubator 7 for 24 hours at 30°C to obtain the seed solution 8, then expand the culture to form the bacterium solution 10; and prepare a concentration of 1 mol / L of calcium source solution 12;

[0060] (2) Select the mixture of gangue, tailings and aeolian sand as coarse aggregate 1, and select fly ash as fine aggregate 5; wherein, the mass ratio of fine aggregate to coarse aggregate is 1:2; coarse aggregate 1. It is transported to the crusher 3 by the belt conveyor 2 for crushing until the particle size is ≤ 25mm, and then transported to the mixer 6 by the belt conveyor 4;

[0061] (3) Pass CO into the bacterial solution 2 Gas 9, formed containing CO 3 2- Bacter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com