Non-crackable rock slab and preparation method thereof

A kind of cracking rock, not easy technology, applied in the field of unbreakable rock slab and its preparation, can solve the problem of easy damage, achieve the effect of improving stress, high breaking strength, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

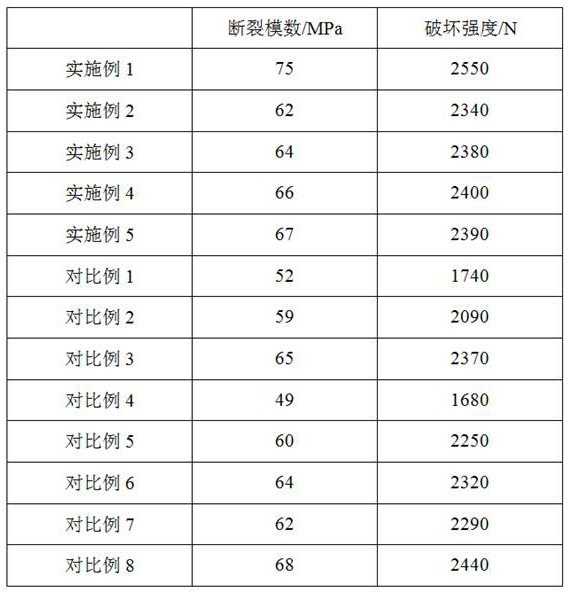

Examples

Embodiment 1

[0030] An unbreakable rock slab, made of the following raw materials in parts by weight: 42 parts of wollastonite, 30 parts of mullite, 16 parts of potassium feldspar, 12 parts of burnt gemstone, 8 parts of burnt talc, 7 parts of high alumina, 5 parts of wollastonite, 4 parts of dolomite, 3 parts of modified silicon carbide, 2.5 parts of strontium carbonate, 1 part of far-infrared ceramic powder, and 20 parts of reinforcing agent.

[0031] The reinforcing agent is composed of the following raw materials in parts by weight: 24 parts of zirconium dioxide, 18 parts of aluminum oxide, 12 parts of scandium oxide, 10 parts of ammonium fluoride, and 6 parts of sodium hydroxymethyl cellulose.

[0032] The preparation method of described modified silicon carbide is:

[0033] S1: Add 4 parts of silicon carbide to 12 parts of 8wt% ammonia solution, stir at 150rpm for 1.2h, filter, and dry to obtain pretreated silicon carbide;

[0034] S2: Add the pretreated silicon carbide obtained in S...

Embodiment 2

[0041] An unbreakable rock slab, made of the following raw materials in parts by weight: 40 parts of wollastonite, 25 parts of mullite, 15 parts of potassium feldspar, 10 parts of burnt gemstone, 6 parts of burnt talc, 5 parts of high alumina, 4 parts of modified silicon carbide, 2 parts of dolomite, 2 parts of magnesium oxide, 2 parts of strontium carbonate, 0.8 parts of far-infrared ceramic powder, and 10 parts of reinforcing agent.

[0042] The reinforcing agent is composed of the following raw materials in parts by weight: 24 parts of zirconium dioxide, 18 parts of aluminum oxide, 12 parts of scandium oxide, 10 parts of ammonium fluoride, and 6 parts of sodium hydroxymethyl cellulose.

[0043] The preparation method of described modified silicon carbide is:

[0044] S1: Add 4 parts of silicon carbide to 12 parts of 8wt% ammonia solution, stir at 150rpm for 1.2h, filter, and dry to obtain pretreated silicon carbide;

[0045] S2: Add the pretreated silicon carbide obtained ...

Embodiment 3

[0052] An unbreakable rock slab, made of the following raw materials in parts by weight: 55 parts of wollastonite, 40 parts of mullite, 20 parts of potassium feldspar, 20 parts of burnt gemstone, 12 parts of burnt talc, 10 parts of high alumina, 8 parts of modified silicon carbide, 6 parts of dolomite, 5 parts of magnesium oxide, 5 parts of strontium carbonate, 1.8 parts of far-infrared ceramic powder, and 25 parts of reinforcing agent.

[0053] The reinforcing agent is composed of the following raw materials in parts by weight: 24 parts of zirconium dioxide, 18 parts of aluminum oxide, 12 parts of scandium oxide, 10 parts of ammonium fluoride, and 6 parts of sodium hydroxymethyl cellulose.

[0054] The preparation method of described modified silicon carbide is:

[0055] S1: Add 4 parts of silicon carbide to 12 parts of 8wt% ammonia solution, stir at 150rpm for 1.2h, filter, and dry to obtain pretreated silicon carbide;

[0056] S2: Add the pretreated silicon carbide obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com