A kind of non-fragile rock slab and preparation method thereof

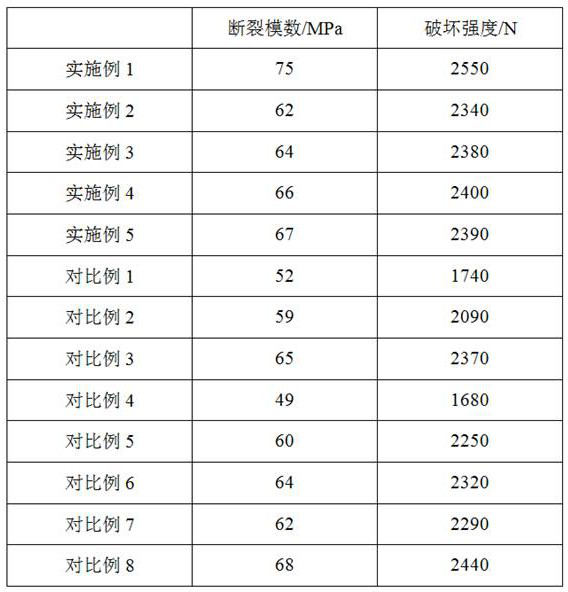

A kind of fractured rock, not easy technology, applied in the field of non-crackable rock slabs and its preparation, can solve the problems of easy damage, etc., and achieve the effect of improving stress, high failure strength, increasing fracture modulus and failure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A non-fragile rock slab is made from the following raw materials in parts by weight: 42 parts of wollastonite, 30 parts of mullite, 16 parts of potassium feldspar, 12 parts of coke gemstone, 8 parts of sintered talc, 7 parts of high alumina, 5 parts of wollastonite, 4 parts of dolomite, 3 parts of modified silicon carbide, 2.5 parts of strontium carbonate, 1 part of far-infrared ceramic powder, 20 parts of reinforcing agent.

[0031] The reinforcing agent is composed of the following raw materials in parts by weight: 24 parts of zirconium dioxide, 18 parts of aluminum oxide, 12 parts of scandium oxide, 10 parts of ammonium fluoride, and 6 parts of sodium hydroxymethyl cellulose.

[0032] The preparation method of the modified silicon carbide is:

[0033] S1: adding 4 parts of silicon carbide to 12 parts of 8wt% ammonia solution, stirring at 150rpm for 1.2h, filtering, and drying to obtain pretreated silicon carbide;

[0034] S2: Add the pretreated silicon carbide obtai...

Embodiment 2

[0041] A non-fragile rock slab is made from the following raw materials in parts by weight: 40 parts of wollastonite, 25 parts of mullite, 15 parts of potassium feldspar, 10 parts of coke gemstone, 6 parts of sintered talc, 5 parts of high alumina, 4 parts of modified silicon carbide, 2 parts of dolomite, 2 parts of magnesium oxide, 2 parts of strontium carbonate, 0.8 parts of far-infrared ceramic powder, 10 parts of reinforcing agent.

[0042] The reinforcing agent is composed of the following raw materials in parts by weight: 24 parts of zirconium dioxide, 18 parts of aluminum oxide, 12 parts of scandium oxide, 10 parts of ammonium fluoride, and 6 parts of sodium hydroxymethyl cellulose.

[0043] The preparation method of the modified silicon carbide is:

[0044] S1: adding 4 parts of silicon carbide to 12 parts of 8wt% ammonia solution, stirring at 150rpm for 1.2h, filtering, and drying to obtain pretreated silicon carbide;

[0045] S2: Add the pretreated silicon carbide o...

Embodiment 3

[0052] A non-fragile rock slab is made from the following raw materials in parts by weight: 55 parts of wollastonite, 40 parts of mullite, 20 parts of potassium feldspar, 20 parts of coke gemstone, 12 parts of sintered talc, 10 parts of high alumina, 8 parts of modified silicon carbide, 6 parts of dolomite, 5 parts of magnesium oxide, 5 parts of strontium carbonate, 1.8 parts of far-infrared ceramic powder, 25 parts of reinforcing agent.

[0053] The reinforcing agent is composed of the following raw materials in parts by weight: 24 parts of zirconium dioxide, 18 parts of aluminum oxide, 12 parts of scandium oxide, 10 parts of ammonium fluoride, and 6 parts of sodium hydroxymethyl cellulose.

[0054] The preparation method of the modified silicon carbide is:

[0055] S1: adding 4 parts of silicon carbide to 12 parts of 8wt% ammonia solution, stirring at 150rpm for 1.2h, filtering, and drying to obtain pretreated silicon carbide;

[0056] S2: Add the pretreated silicon carbide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com