Preparation method of fullerene-modified polyetherimide polymer material

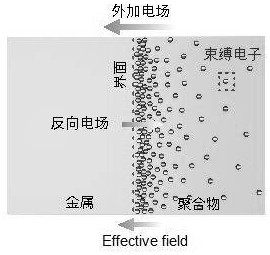

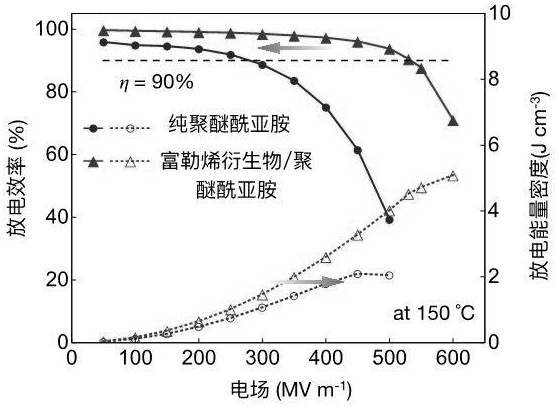

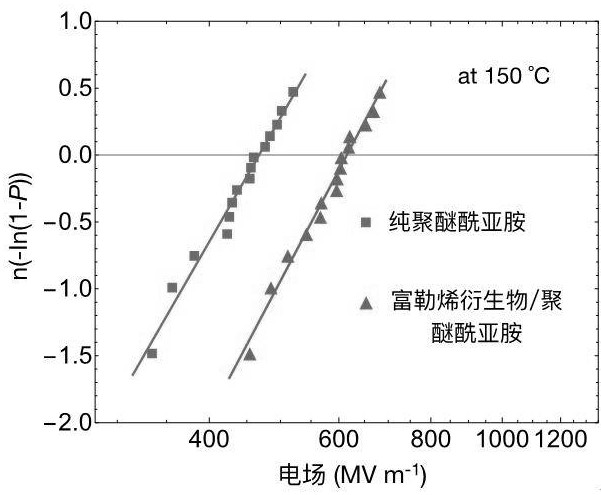

A technology of polyetherimide and polymer materials, which is applied in fixed capacitance parts, laminated capacitors, film/thick film capacitors, etc., can solve the problem of not being able to adapt to the working voltage environment and the imide breakdown field strength is not high , increase in conductance loss, etc., to achieve the effects of inhibiting carrier migration, increasing breakdown field strength, and reducing conductance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings.

[0027] A preparation method of a fullerene-modified polyetherimide polymer material, the preparation raw materials include fullerene-based small molecules, polyetherimide, and N-methylpyrrolidone solution, and the preparation step includes a mixing step, Drying step and peeling step, the mixing step, drying step and peeling step are carried out in sequence, the mixing step is to obtain a composite suspension, and the drying step uses the composite suspension to obtain a composite wet film, and then removes The volume in the composite wet film yields a composite film, and the peeling step peels off the composite film.

[0028] In the mixing step, polyetherimide is first added to the N-methylpyrrolidone solution to obtain a polyetherimide solution, and then fullerene-based small molecules are added to obtain a composite suspension,

[0029] In the mixing step, the mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com