Macro preparation method of boron nitride epoxy resin transparent coating

A boron nitride epoxy resin and transparent coating technology, which is applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of strong and difficult large-scale preparation, poor dispersion, and industrial application obstacles, and achieve sustainable Effect of long-term protective performance, high transparency and good light transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

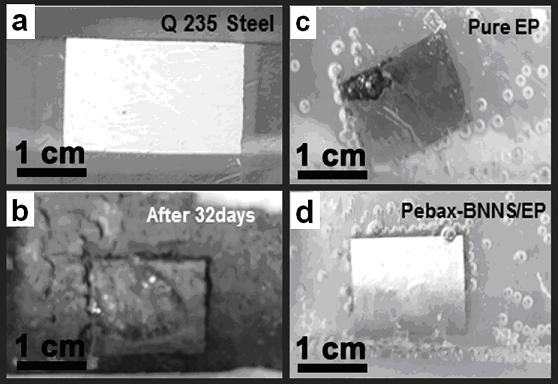

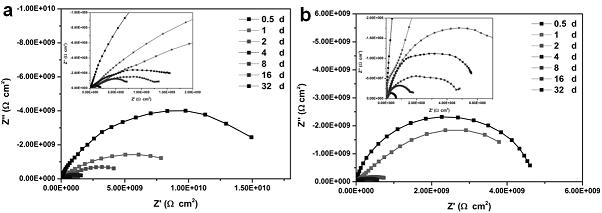

Examples

Embodiment 1

[0027] Embodiment 1 A kind of macro-preparation method of boron nitride epoxy resin transparent coating comprises the following steps:

[0028] ⑴ After mixing hexagonal boron nitride (h-BN) and polyether block amide 1657 (Pebax) at a mass ratio (g / g) of 2:13, place it in a high-temperature shear furnace and mechanically shear it at 180°C for 4 hours Finally, the mixture is extruded, and the mixture is naturally cooled to room temperature to obtain the Pebax functionalized hexagonal boron nitride nanosheet composite material, which is referred to as the Pebax-BNNSs composite material.

[0029] (2) According to the ratio of 0.01 g / mL, the Pebax-BNNSs composite material was dissolved in ethanol aqueous solution, heated to 120°C with an oil bath and fully dissolved under the action of magnetic stirring to obtain a suspension; Filtrate and disperse with an ultrasonic machine to obtain a Pebax-BNNSs dispersion. The purpose of filtering and dispersing is to filter larger particles a...

Embodiment 2

[0031] Embodiment 2 A kind of macro-preparation method of boron nitride epoxy resin transparent coating comprises the following steps:

[0032] ⑴ After mixing hexagonal boron nitride (h-BN) and polyether block amide 1657 (Pebax) at a mass ratio of 2:13, place it in a high-temperature shear furnace at 180°C for 4 hours and extrude the mixture , after the mixture is naturally cooled to room temperature, the Pebax functionalized hexagonal boron nitride nanosheet composite material is obtained, which is referred to as the Pebax-BNNSs composite material.

[0033] (2) According to the ratio of 0.02 g / mL, the Pebax-BNNSs composite material was dissolved in ethanol aqueous solution, heated to 150°C with an oil bath and fully dissolved under the action of magnetic stirring to obtain a suspension; the suspension was successively washed with a centrifuge Filtrate and disperse with an ultrasonic machine to obtain a Pebax-BNNSs dispersion. The purpose of filtering and dispersing is to fil...

Embodiment 3

[0035] Embodiment 3 A kind of macro-preparation method of boron nitride epoxy resin transparent coating comprises the following steps:

[0036] ⑴ After mixing hexagonal boron nitride (h-BN) and polyether block amide 1657 (Pebax) at a mass ratio of 2:15, place it in a high-temperature shearing furnace and mechanically shear it at 300°C for 3 hours, then extrude the mixture , after the mixture is naturally cooled to room temperature, the Pebax functionalized hexagonal boron nitride nanosheet composite material is obtained, which is referred to as the Pebax-BNNSs composite material.

[0037] (2) Dissolve the Pebax-BNNSs composite material in ethanol aqueous solution at a ratio of 0.03 g / mL, heat it to 180°C with an oil bath and stir it under magnetic force until it is fully dissolved to obtain a suspension; Filtrate and disperse with an ultrasonic machine to obtain a Pebax-BNNSs dispersion. The purpose of filtering and dispersing is to filter larger particles and obtain high-quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com