Preparation method and use method of moisture-cured polyurethane edge sealing glue with high initial adhesion

A polyurethane hot-melt adhesive, moisture-curing technology, used in polyurea/polyurethane adhesives, non-polymer adhesive additives, adhesives, etc., can solve problems such as high initial tack, and achieve fast curing speed and peel strength. The effect of large and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

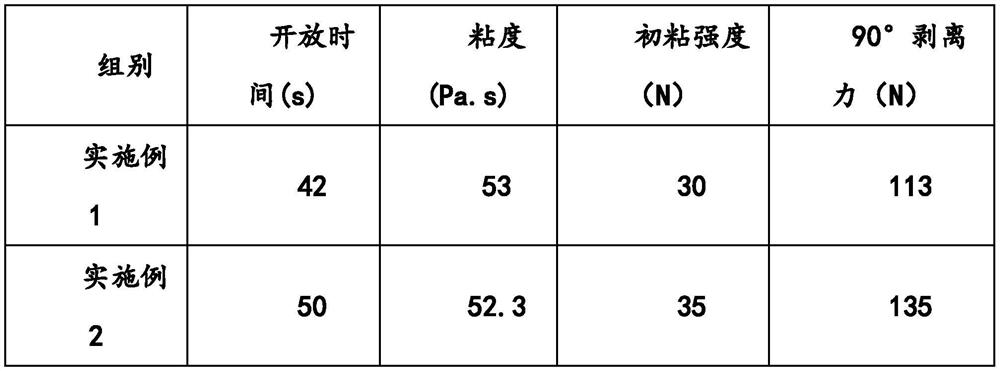

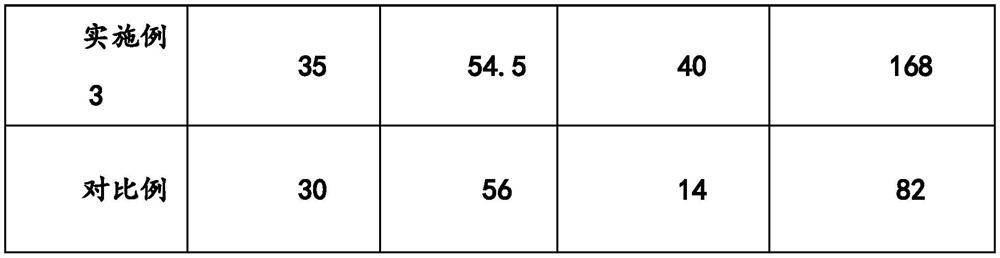

Examples

Embodiment 1

[0017] A moisture-curing polyurethane edge banding adhesive with high initial tack is prepared from the following raw materials in parts by mass: 3 parts of polypropylene glycol ether, 5 parts of polytetrahydrofuran, 18 parts of amorphous polyester 7110, and 15 parts of polyadipate Neopentyl glycol, 20 parts of polyhexamethylene adipate, 12 parts of terpene resin, 5 parts of copolyester resin, 10 parts of talc, 12 parts of MDI-100.

[0018] The preparation method of the moisture-cured polyurethane hot-melt adhesive for edge sealing comprises the steps:

[0019] Weigh the above raw materials according to the above mass ratio, first mix polypropylene glycol ether, polytetrahydrofuran, amorphous polyester 7110, polyneopentyl adipate, polyhexamethylene adipate, terpene resin, copolyester resin Put it into the reaction kettle, heat up to 140°C under the pressure of 0.095MPa ~ 0.1MPa to melt, dehydrate until the liquid material has no bubbles to escape, then add talc powder in batch...

Embodiment 2

[0021] A moisture-curing polyurethane edge banding adhesive with high initial tack is prepared from the following raw materials in parts by mass: 4 parts of polypropylene glycol ether, 5 parts of polytetrahydrofuran, 15 parts of amorphous polyester 7110, and 20 parts of polyadipate Neopentyl glycol, 20 parts of polyhexamethylene adipate, 10 parts of terpene resin, 5 parts of copolyester resin, 10 parts of talc, 11 parts of MDI-100.

[0022] The preparation method of the moisture-cured polyurethane hot-melt adhesive for edge sealing comprises the steps:

[0023] Weigh the above raw materials according to the above mass ratio, first mix polypropylene glycol ether, polytetrahydrofuran, amorphous polyester 7110, polyneopentyl adipate, polyhexamethylene adipate, terpene resin, copolyester resin Put it into the reaction kettle, heat up to 140°C under the pressure of 0.095MPa ~ 0.1MPa to melt, dehydrate until the liquid material has no bubbles to escape, then add talc powder in batch...

Embodiment 3

[0025] A moisture-curing polyurethane edge banding adhesive with high initial tack is prepared from the following raw materials in parts by mass: 5 parts of polypropylene glycol ether, 8 parts of polytetrahydrofuran, 15 parts of amorphous polyester 7110, and 15 parts of polyadipate Neopentyl glycol, 20 parts of polyhexamethylene adipate, 10 parts of terpene resin, 5 parts of copolyester resin, 10 parts of talc, 12 parts of MDI-100.

[0026] The preparation method of the moisture-cured polyurethane hot-melt adhesive for edge sealing comprises the steps:

[0027] Weigh the above raw materials according to the above mass ratio, first mix polypropylene glycol ether, polytetrahydrofuran, amorphous polyester 7110, polyneopentyl adipate, polyhexamethylene adipate, terpene resin, copolyester resin Put it into the reaction kettle, heat up to 140°C under the pressure of 0.095MPa ~ 0.1MPa to melt, dehydrate until the liquid material has no bubbles to escape, then add talc powder in batch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com