Wide-range linear pressure sensor based on Mach-Zehnder structure and detection method thereof

A pressure sensor and linear pressure technology, which is applied in the direction of fluid pressure measurement using optical methods, measuring fluid pressure, converting sensor output, etc., can solve problems such as small central wavelength, inconvenient factory calibration and post-calibration, and low resolution of pressure sensors , to achieve the effect of small size, low production cost and strong structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

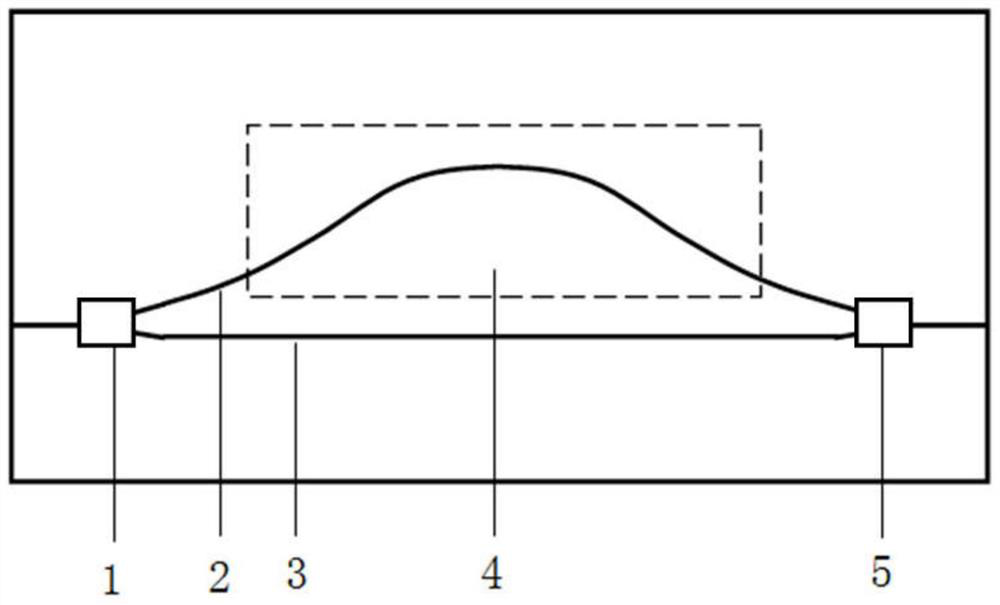

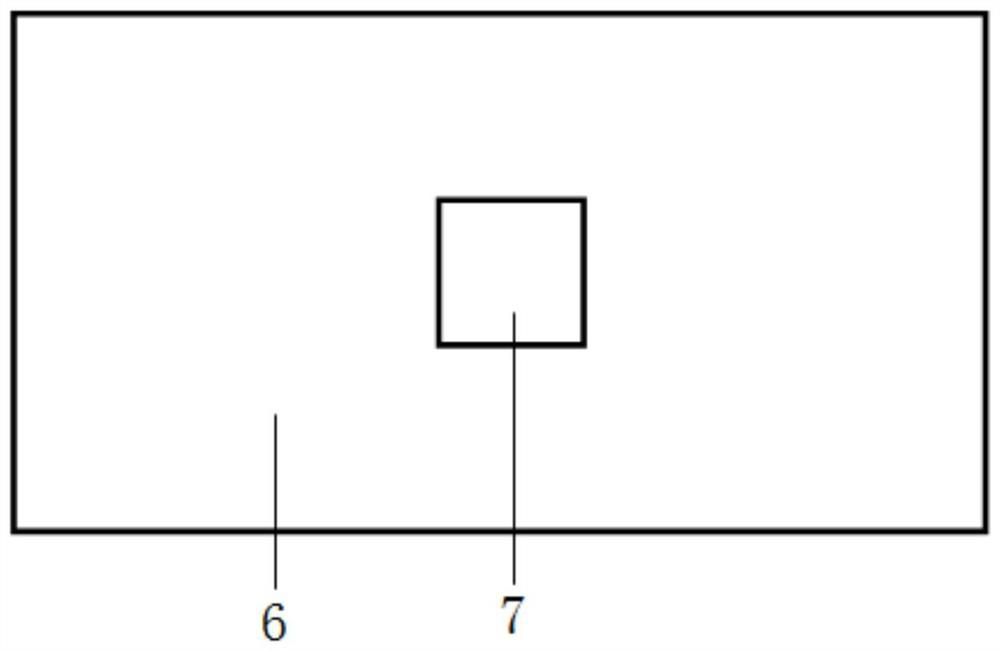

[0046] A large range linear pressure sensor based on the Mach-Zehnder structure, such as figure 1 As shown, the sensor includes a wide-spectrum light source, a Mach-Zehnder structure and a spectrometer. The Mach-Zehnder structure includes an input beam splitter 1, two interference arms with different lengths, an output beam combiner 5, and an input beam splitter 1. The two output ports are respectively connected to one end of the two interference arms, and the other ends of the two interference arms are respectively connected to the two input ports of the output beam combiner 5; a pressure sensing area 4 is set on one of the interference arms.

[0047] When the pressure acts on the pressure sensing area 4, it will cause the effective refractive index of the interference arm in the pressure sensing area 4 to change, thereby causing the change of the central wavelength of the output spectrum of the device, and the effective refractive index of the interference arm in the pressure...

Embodiment 2

[0057] Embodiment 1 provides a detection method based on a Mach-Zehnder structure of a large-range linear pressure sensor, including the following steps:

[0058] (1) Input broad-spectrum light into the pressure sensor, and use a spectrometer to detect the output spectrum of the pressure sensor, and obtain the central wavelength λ of the device output spectrum when no pressure is applied 0 ;

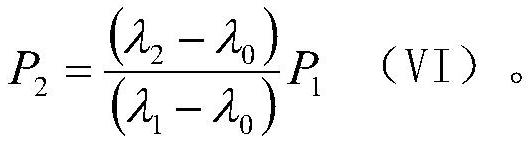

[0059] (2) Apply a pressure block on the pressure sensing area 4 or expose the pressure sensing area 4 to the pressure measurement area, and apply a known pressure P 1 , and input the broad-spectrum light into the pressure sensor, detect the output spectrum of the pressure sensor by a spectrometer, and obtain the central wavelength λ of the output spectrum of the device under the current known pressure 1 , complete the calibration of the device; thereby determine the linear relationship between the pressure applied on the pressure sensing area 4 and the change of the central wavelength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Cross section width | aaaaa | aaaaa |

| Cross section thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com