Packaging method of GaAs-based LED lamp bead

A technology of LED lamp beads and packaging methods, which is applied in the field of optoelectronics, can solve the problems of conductive silver glue leakage and other problems, and achieve the effect of eliminating leakage, avoiding leakage, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A packaging method for GaAs-based LED lamp beads, comprising the following steps:

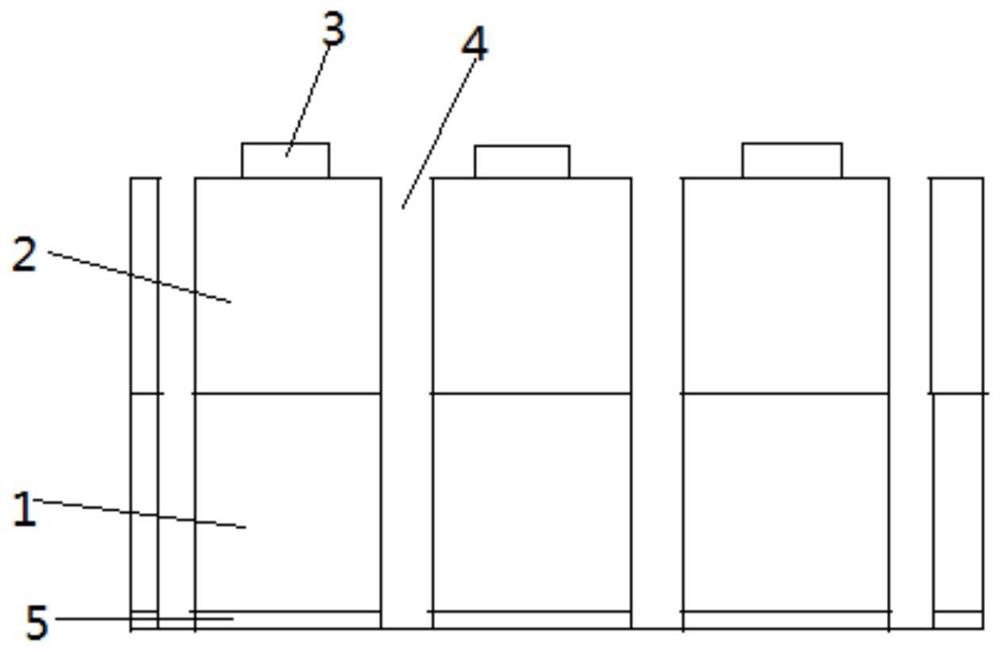

[0029] (1) GaAs-based light-emitting diode chip epitaxial layer is grown on GaAs substrate 1, and P electrode 3 and N electrode of light-emitting diode chip are prepared by conventional P-side metal deposition, photolithography P-electrode, thinning, and N-side metal deposition methods 5;

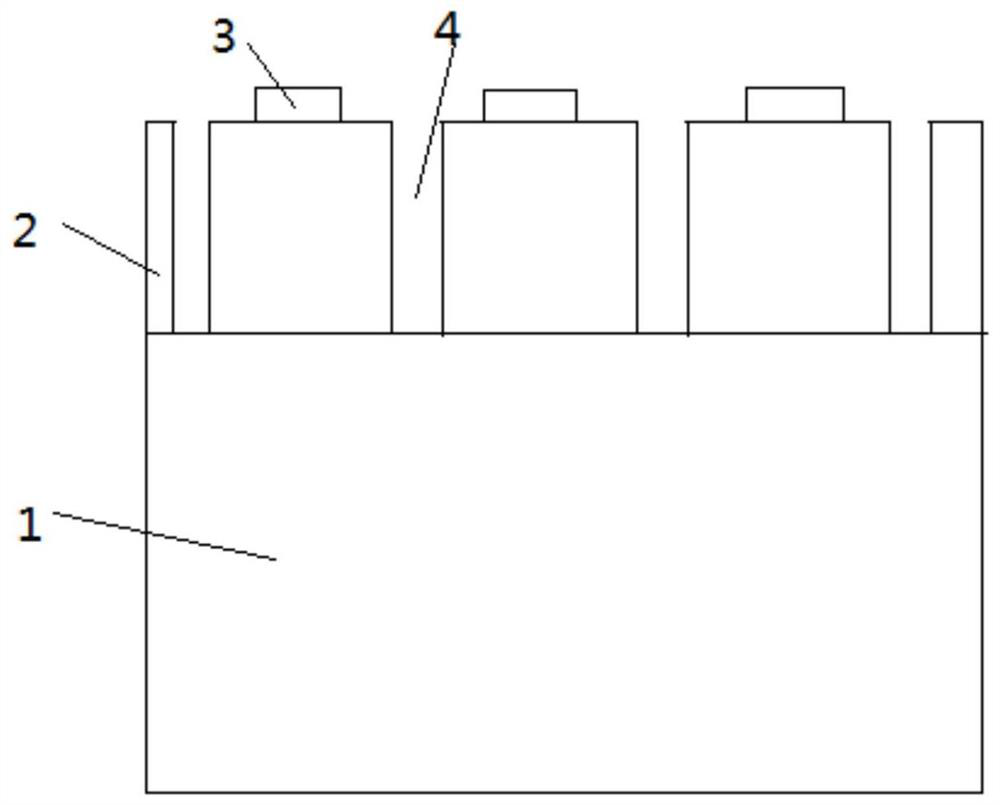

[0030] (2) Carry out P-face cutting to the GaAs-based light-emitting diode chip that step (1) makes, as figure 1 As shown, a diamond knife is used to form a strip-shaped dicing line 4 around the P electrode 3. The period of the dicing line 4 is consistent with the period of the P electrode 3, and the dicing line 4 does not completely separate the GaAs-based light-emitting diode chip (the epitaxial layer has been cut through. and cut to the substrate), the cut chip is routinely tested to obtain the photoelectric parameters of the chip, which can be tested by conventional methods, such as placing the c...

Embodiment 2

[0035] A packaging method for GaAs-based LED lamp beads, as shown in Example 1, the difference is that the cutting depth in step (2) is 1 / 4 chip thickness, and the chip thickness here includes GaAs substrate and epitaxial layer thickness;

[0036] The width of the scribe line 4 is 25 μm.

Embodiment 3

[0038] A packaging method for GaAs-based LED lamp beads, as shown in Embodiment 1, the difference is that the thickness of the packaging metal substrate with magnetism is 30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com