Method for preparing high-performance nanofiltration membrane by constructing ZIF-8 intermediate layer

A technology of ZIF-8 and intermediate layer, which is applied in the field of membrane material modification, can solve the problems of low flux of nanofiltration membranes, and achieve the effect of uniform structure, small thickness and low agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

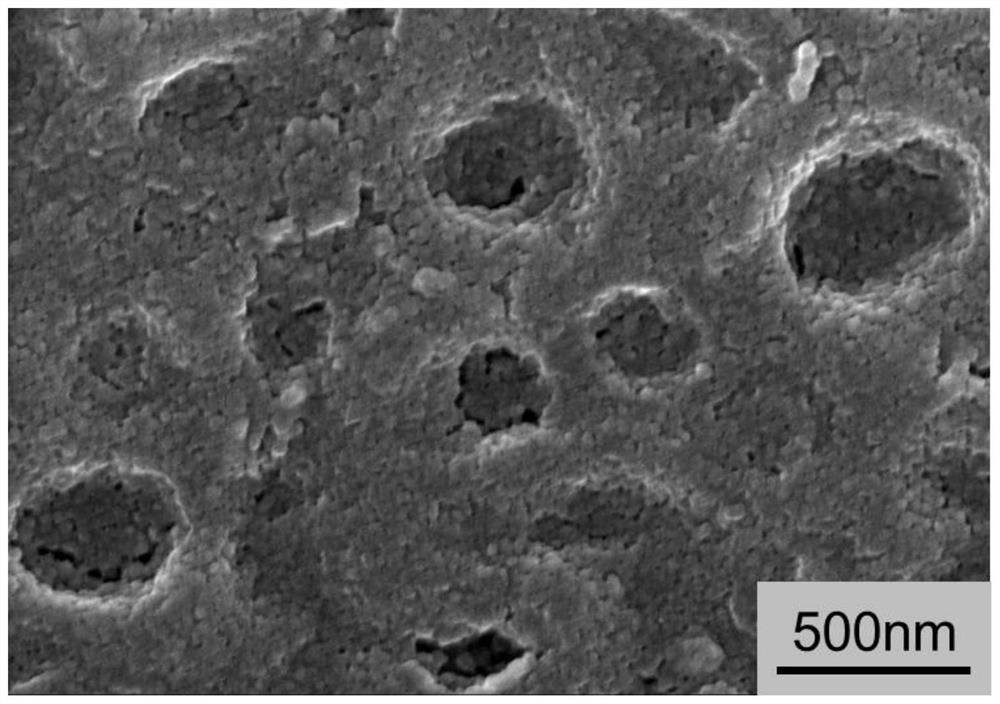

Embodiment 1

[0034] Using polyethersulfone microfiltration membrane as the supporting base membrane, pour an aqueous solution containing 0.1mol / L zinc nitrate and 1wt% sodium polystyrene sulfonate on the surface of the supporting base membrane, pour off the excess liquid after contacting for 12 hours, and remove the surface of residual liquid. Subsequently, the n-hexane / 1-octanol solution containing 0.8wt% dimethylimidazole in a volume ratio of 9:1 was poured on the surface of the membrane. Rinse membrane. The membrane was annealed at 60°C for 30 minutes. After cooling to room temperature, an aqueous solution containing 2.0 wt% piperazine was poured on the surface of the membrane. After contacting for 2 minutes, the excess solution was poured off and the remaining liquid on the surface was removed. The n-hexane solution containing 0.2 wt% trimesoyl chloride was poured onto the surface of the diaphragm, and after contacting for 1 min, the excess solution was poured off. The obtained film ...

Embodiment 2

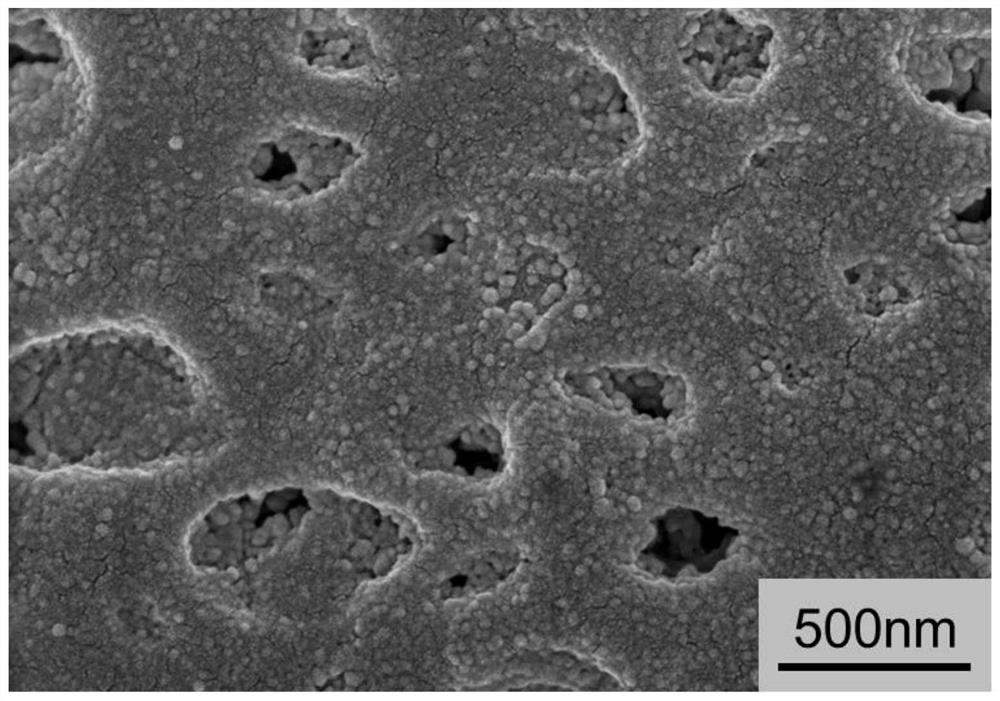

[0037]Using the polyethersulfone microfiltration membrane as the supporting base membrane, pour an aqueous solution containing 0.2mol / L zinc nitrate and 0.5wt% sodium polystyrene sulfonate on the surface of the supporting base membrane, pour off the excess liquid after contacting for 8 hours, and remove residual liquid on the surface. Subsequently, the n-hexane / 1-octanol solution containing 1.0wt% dimethylimidazole in a volume ratio of 8:2 was poured on the surface of the membrane. Rinse membrane. The membrane was annealed at 60°C for 30 minutes. After cooling to room temperature, an aqueous solution containing 1.0 wt% piperazine was poured on the surface of the membrane. After contacting for 2 minutes, the excess solution was poured off and the remaining liquid on the surface was removed. The n-hexane solution containing 0.1 wt% trimesoyl chloride was poured onto the surface of the diaphragm, and after contacting for 1 min, the excess solution was poured off. The obtained f...

Embodiment 3

[0039] Embodiment 3 (The addition of Embodiment 3 and Embodiment 4 is to make the upper and lower limits of the parameters in the claims supported)

[0040] With the polysulfone microfiltration membrane as the supporting base membrane, pour the aqueous solution containing 0.05mol / L zinc nitrate and 2wt% sodium polystyrene sulfonate on the surface of the supporting base membrane, pour off the excess liquid after contacting for 5 hours, and remove the surface Residual liquid. Subsequently, the n-hexane / 1-octanol solution containing 1.2wt% dimethylimidazole in a volume ratio of 7:3 was poured on the surface of the membrane. Rinse membrane. The membrane was thermally annealed at 70°C for 15 minutes. After cooling to room temperature, an aqueous solution containing 5wt% piperazine was poured on the surface of the membrane. After contacting for 5 minutes, the excess solution was poured off and the remaining liquid on the surface was removed. The n-hexane solution containing 0.5 wt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com