CaMnO3 type perovskite material as well as preparation method and application thereof

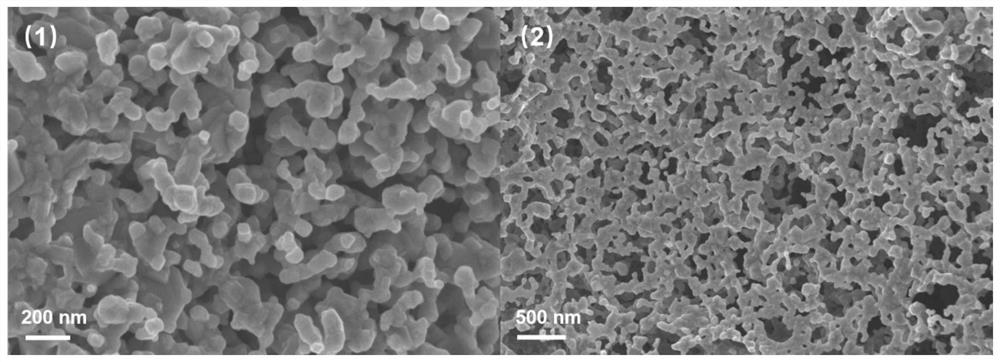

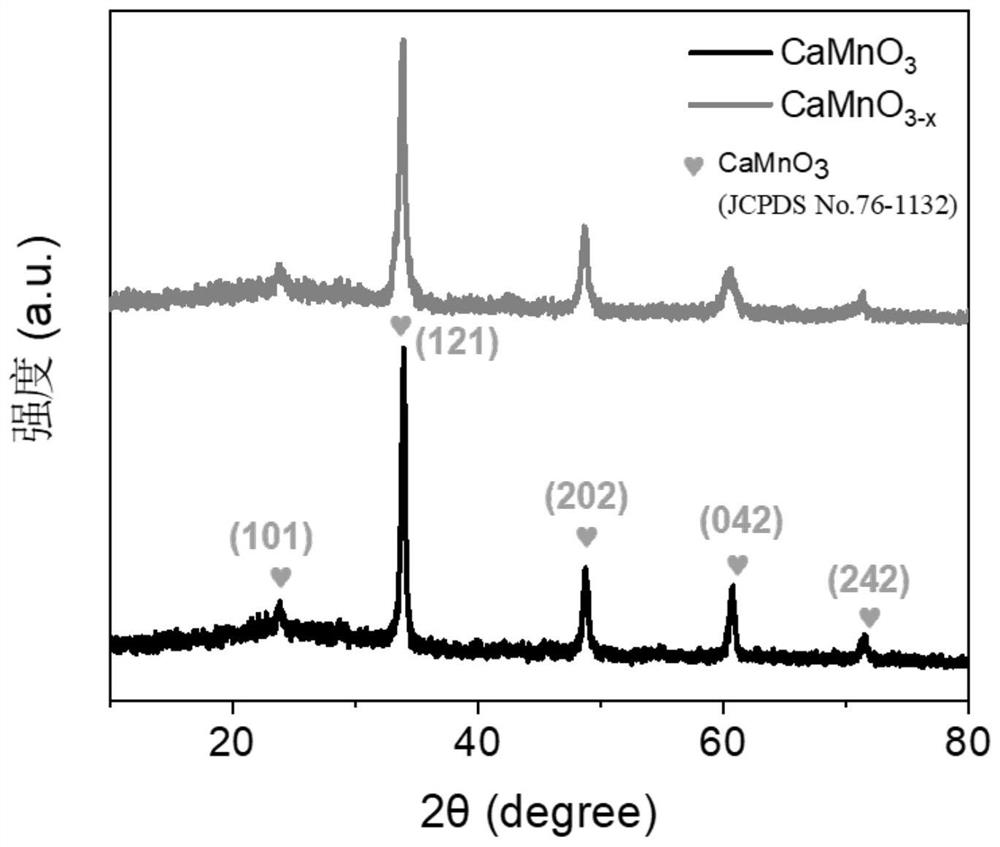

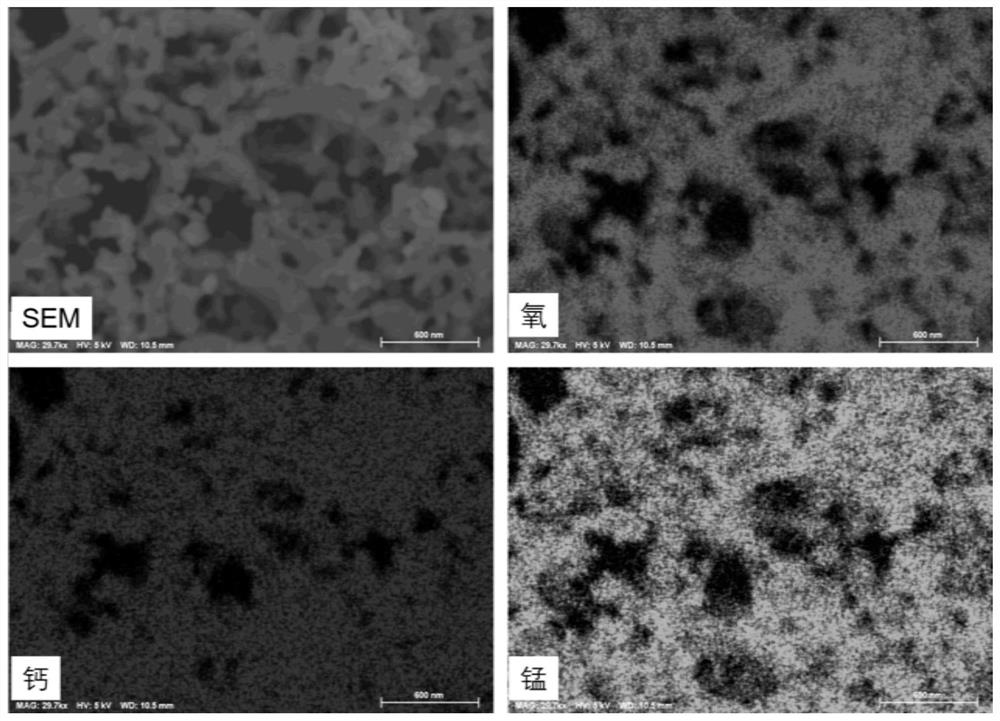

A technology of perovskite materials and powder materials, applied in the field of electrocatalytic materials, can solve the problems of low redox catalytic activity and stability of perovskite materials, and achieve high redox catalytic activity, high catalytic activity and high stability. , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of CaMnO 3 The preparation method of the type perovskite material includes the following steps:

[0048] S1. Dissolve calcium carbonate, manganese nitrate and citric acid in water to obtain a mixed solution, and add concentrated nitric acid dropwise to adjust the pH to 3; heat in an oil bath at 80°C for 12 hours to obtain a sol; freeze-dry the formed sol for 48 hours to form a powder Material; the molar ratio of the calcium salt, manganese salt and citric acid is 1:1:2;

[0049] S2. The powder material obtained in step S1 is calcined at 400°C for 5 hours, and then at 800°C for 6 hours;

[0050] S3. Heat at 500℃ for 1h in ammonia gas to produce CaMnO 3 Type perovskite material (denoted as CaMnO 3-x Or CMO-500).

Embodiment 2~10

[0052] CaMnO of Examples 2-10 3 The preparation method of the type perovskite material is the same as that of Example 1, except that the preparation conditions in Table 1 are changed as follows:

[0053] Table 1 Preparation conditions of each embodiment

[0054]

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Limiting current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com