Ultra-thin water-based fireproof temperature control coating and preparation method thereof

An ultra-thin, water-based technology, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of forming protection, not being able to block heat, softening and burning of plastic materials in battery compartments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

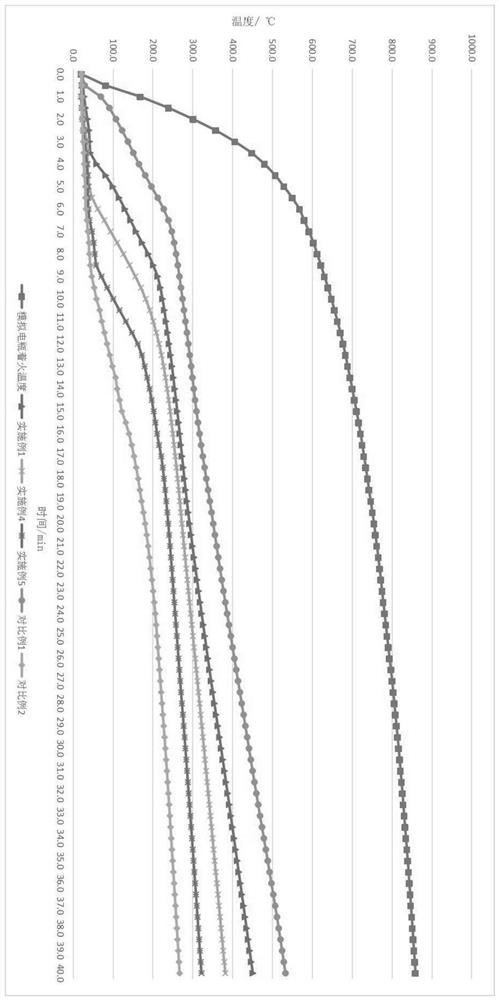

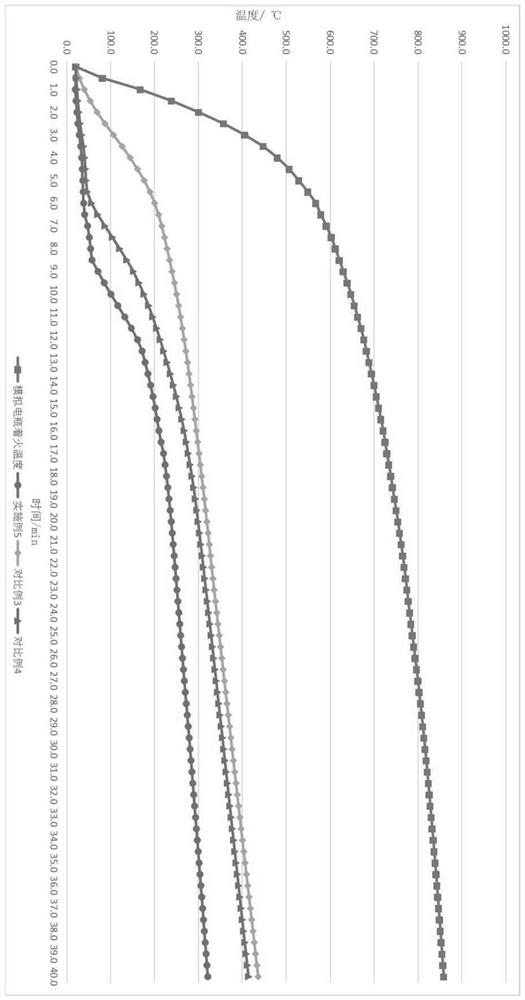

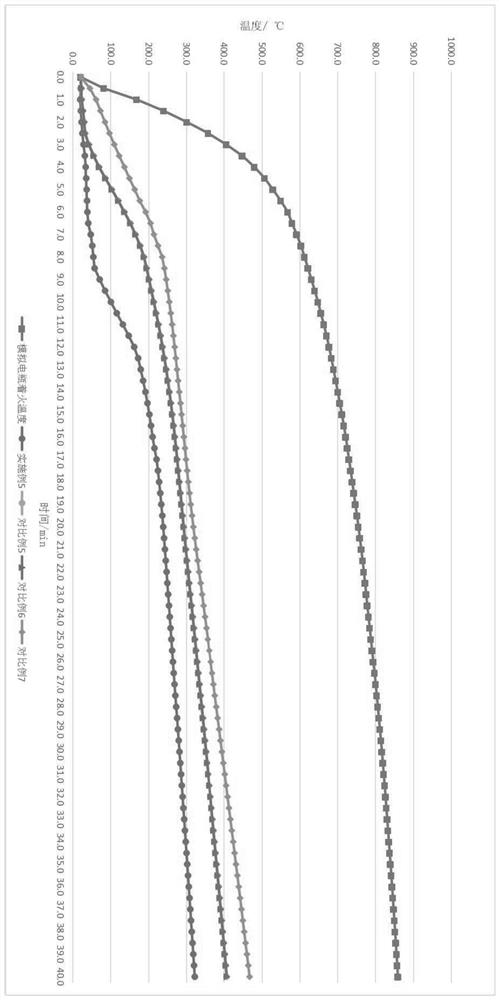

Image

Examples

Embodiment 1

[0038] An ultra-thin water-based fire-proof and temperature-controlling coating, including an energy storage connection primer layer and an ultra-thin water-based fire-proof and temperature-controlling coating;

[0039] As shown in Table 1, the energy storage connection primer includes the following components (in Kg):

[0040] Table 1

[0041] components content Acrylic copolymer emulsion 70 Hollow Ceramic Microspheres 15 Phase Change Powder Microcapsules 15

[0042] As shown in Table 2, the ultra-thin water-based fireproof and temperature-controlling coating includes the following components (in Kg):

[0043] Table 2

[0044] components content components content fire retardant lotion 15 Titanium dioxide 8 Deionized water 15 Intumescent flame retardant powder 50 Mixing aid 4 Phase Change Powder Microcapsules 10 Coalescent 3

[0045]The mixing aid includes the following input compone...

Embodiment 2

[0054] An ultra-thin water-based fire-proof and temperature-controlling coating, including an energy storage connection primer layer and an ultra-thin water-based fire-proof and temperature-controlling coating;

[0055] As shown in Table 3, the energy storage connection primer includes the following components (in Kg):

[0056] table 3

[0057] components content Acrylic copolymer emulsion 60 Hollow Ceramic Microspheres 10 Phase Change Powder Microcapsules 10

[0058] As shown in Table 4, the ultra-thin water-based fireproof and temperature-controlling coating includes the following components (in Kg):

[0059] Table 4

[0060] components content components content fire retardant lotion 10 Titanium dioxide 5 Deionized water 10 Intumescent flame retardant powder 40 Mixing aid 2 Phase Change Powder Microcapsules 8 Coalescent 2

[0061] The mixing aid includes the following input compone...

Embodiment 3

[0069] An ultra-thin water-based fire-proof and temperature-controlling coating, including an energy storage connection primer layer and an ultra-thin water-based fire-proof and temperature-controlling coating;

[0070] As shown in Table 5, the energy storage connection primer includes the following components (in Kg):

[0071] table 5

[0072] components content Acrylic copolymer emulsion 80 Hollow Ceramic Microspheres 20 Phase Change Powder Microcapsules 20

[0073] As shown in Table 6, the ultra-thin water-based fireproof and temperature-controlling coating includes the following components (in Kg):

[0074] Table 6

[0075] components content components content fire retardant lotion 20 Titanium dioxide 10 Deionized water 20 Intumescent flame retardant powder 60 Mixing aid 5 Phase Change Powder Microcapsules 15 Coalescent 5

[0076] The mixing aid includes the following input compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com