Antibacterial powder coating and preparation method thereof

An antibacterial powder and paint technology, applied in the field of antibacterial powder paint and its preparation, can solve problems such as affecting the use of paint, prone to mildew, and reducing aesthetics, and achieve the effect of preventing bacterial metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

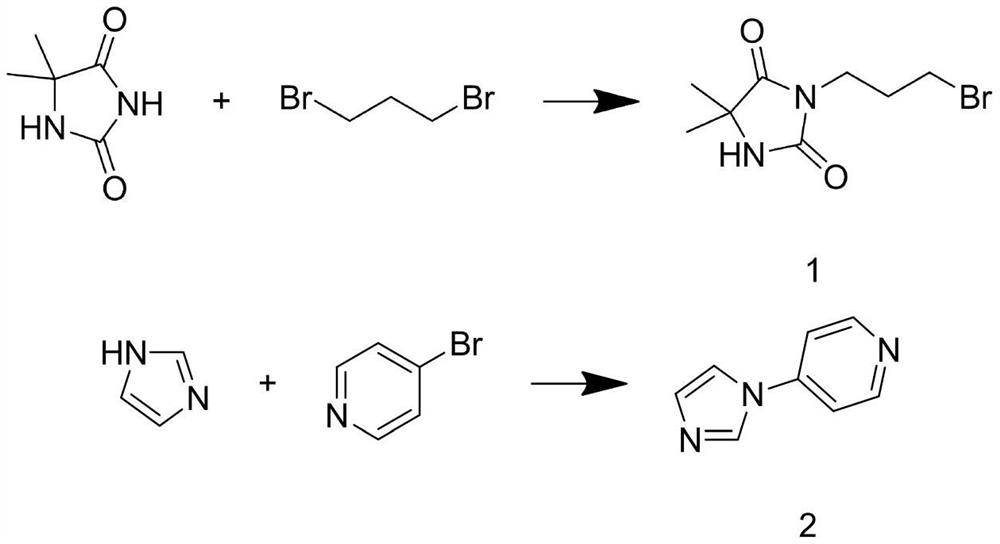

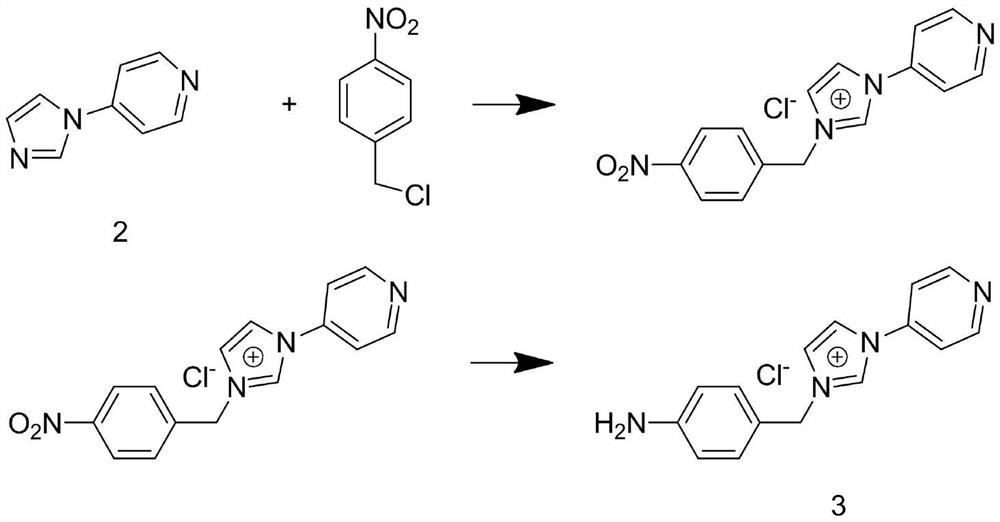

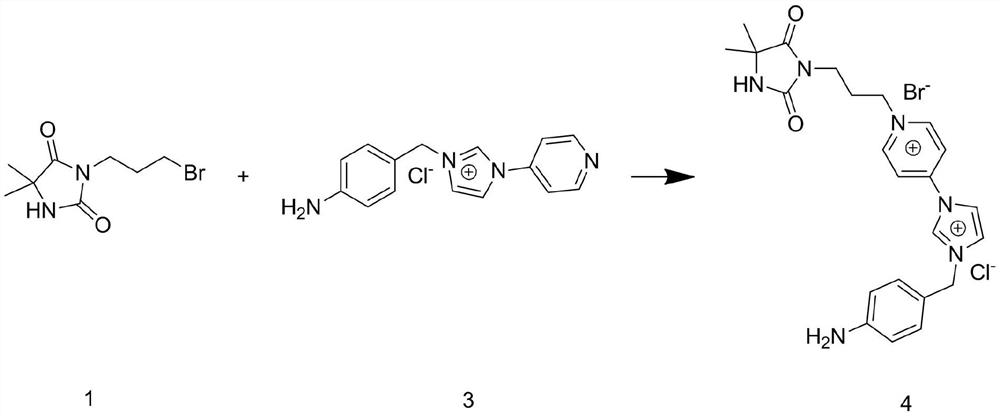

Method used

Image

Examples

Embodiment 1

[0040] An antibacterial powder coating, made of the following raw materials in parts by weight: 50 parts of E-12 epoxy resin, 8 parts of titanium dioxide, 3 parts of zinc oxide, 0.5 part of leveling agent 6588, 8 parts of antibacterial filler, 0.5 part of brightening agent C701;

[0041] The powder coating is made by the following steps:

[0042] Step S1: Weighing the above-mentioned raw materials, adding the raw materials into a stirred tank, and stirring for 10 min under the condition of a rotating speed of 500 r / min, to obtain a mixture;

[0043] Step S2: adding the mixture into a twin-screw extruder, extruding and cooling at a temperature of 85° C., to obtain a coating base material;

[0044] Step S3: cutting and pulverizing the coating base material, and passing through a 15 μm sieve to obtain an antibacterial powder coating.

[0045] Described antibacterial filler is made by following steps:

[0046] Step A1: Dissolve sodium hydroxide in deionized water to prepare a d...

Embodiment 2

[0054] An antibacterial powder coating, made of the following raw materials in parts by weight: 60 parts of E-12 epoxy resin, 9 parts of titanium dioxide, 4 parts of zinc oxide, 1 part of leveling agent 6588, 9 parts of antibacterial filler, 0.6 part of brightening agent C701;

[0055] The powder coating is made by the following steps:

[0056] Step S1: Weighing the above-mentioned raw materials, adding the raw materials into a stirring tank, and stirring for 13 minutes under the condition of a rotating speed of 600 r / min, to obtain a mixture;

[0057] Step S2: adding the mixture into a twin-screw extruder, extruding and cooling at a temperature of 100° C., to obtain a coating base material;

[0058] Step S3: cutting and pulverizing the paint base material, and passing through a 18 μm sieve to obtain an antibacterial powder paint.

[0059] Described antibacterial filler is made by following steps:

[0060] Step A1: Dissolve sodium hydroxide in deionized water to prepare a d...

Embodiment 3

[0068] An antibacterial powder coating, made of the following raw materials in parts by weight: 80 parts of E-12 epoxy resin, 10 parts of titanium dioxide, 5 parts of zinc oxide, 1.5 parts of leveling agent 6588, 10 parts of antibacterial filler, 0.8 parts of brightening agent C701;

[0069] The powder coating is made by the following steps:

[0070] Step S1: Weighing the above-mentioned raw materials, adding the raw materials into a stirring tank, and stirring for 15 minutes under the condition of a rotating speed of 800 r / min, to obtain a mixture;

[0071] Step S2: adding the mixture into a twin-screw extruder, extruding and cooling at a temperature of 155° C., to obtain a coating base material;

[0072] Step S3: cutting and pulverizing the coating base material, and passing through a 20 μm sieve to obtain an antibacterial powder coating.

[0073] Described antibacterial filler is made by following steps:

[0074] Step A1: Dissolve sodium hydroxide in deionized water to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com