Silicon-based composite material for negative active material, negative plate and lithium ion battery

A technology of silicon-based composite materials and negative electrode active materials, applied in battery electrodes, secondary batteries, and secondary battery repair/maintenance, etc., can solve the problems of severe cycle decay and low initial efficiency of silicon negative electrodes, and achieve slow cycle decay. , Improve the first effect and battery capacity, and promote the effect of regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070]

[0071] The present invention also provides a method for preparing the above-mentioned silicon-based composite material for the negative electrode active material, the method comprising the steps of:

[0072] The silicon-based composite material is prepared by mixing single-walled carbon nanotubes, an inorganic solid electrolyte, optionally a first conductive agent, and a silicon material, and heating to a temperature above the melting temperature of the inorganic solid electrolyte.

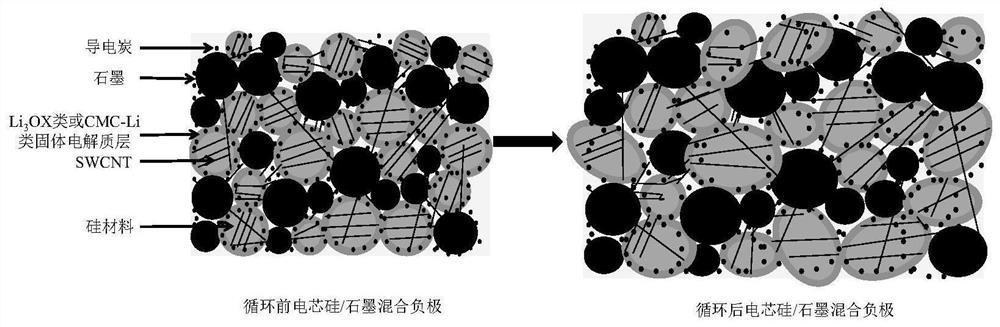

[0073]Wherein, during the heating process, the inorganic solid electrolyte will be melted, fully mixed with the single-walled carbon nanotubes, and optionally the first conductive agent, and coated on the surface of the silicon material particles, that is, a three-dimensional electrolyte is formed on the surface of the silicon material particles. A conductive network and a stable solid electrolyte coating, while the single-walled carbon nanotubes and optionally the first conductive agent...

Embodiment 1

[0127] (1) Preparation of negative electrode sheet

[0128] 0.95g of conductive carbon black SP, 0.05g of single-walled carbon nanotube SWCNT, 1g of Li 3 Mix OCl and 98g of SiO evenly, heat to 300°C, the molten Li 3 OCl can combine SP, SWCNT and Li 3 OCl is uniformly coated on the surface of SiO particles, and a silicon composite material is prepared.

[0129]12g of the prepared silicon composite material was mixed with 84g of graphite, then 2g of conductive agent SP, 2g of binder PVDF and solvent NMP were added, and stirred for 2 hours to prepare a negative electrode slurry with a solid content of 50wt%. The negative electrode slurry is evenly coated on both sides of the copper foil, dried and compacted by a roller press to obtain a negative electrode sheet.

[0130] (2) Preparation of positive electrode sheet

[0131] Mix 95g of positive electrode active material ternary nickel-cobalt-manganese NCM, 2g of binder PVDF and 3g of conductive carbon black as a conductive agen...

Embodiment 2

[0135] The difference from Example 1 is in step (1):

[0136] 17g of a 4% SWCNT aqueous solution and 108g of a 1.5% polymer solid electrolyte CMC-Li (number average molecular weight of 50,000) aqueous solution were placed in a stirring tank and stirred for 60 minutes to prepare a SWCNT-CMC-Li mixed solution.

[0137] Take 32g of SWCNT-CMC-Li mixed solution and place it in a stirring tank, add 1g of conductive agent SP and 26g of deionized water, and stir for 60 minutes to prepare a conductive adhesive, then add 10g of SiO, and stir for 90 minutes to prepare a silicon composite material precursor .

[0138] The silicon composite material precursor prepared above was mixed with 88g graphite material, 65g SWCNT-CMC-Li mixed solution, 4g binder SBR and 27g deionized water, and stirred for 2h to prepare a negative electrode slurry with a solid content of 50wt%. The negative electrode slurry is evenly coated on both sides of the copper foil, dried and compacted by a roller press to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com