Preparation method of DHA low-fat yoghourt

A technology of fatty acid and yogurt, applied in milk preparations, dairy products, applications, etc., can solve the problems of poor taste of skim yogurt, whey separation, etc., and achieve the goal of improving product stability, reducing fat intake, and improving nutritional value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

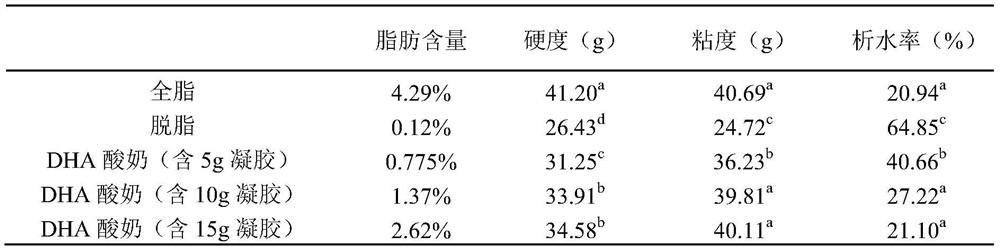

[0030] Step 1) Prepare emulsion filling gel: algae oil (DHA content 10%) and emulsifier are processed twice by homogenizer 30MPa to obtain DHA-O / W emulsion. Add water to the rice starch and put it into a vacuum packaging bag, shake it well, put it into an ultra-high pressure treatment device for 10 minutes of ultra-high pressure treatment at 400MPa, add a medium-temperature α-amylase at a ratio of 0.1% after treatment, and perform enzymatic hydrolysis treatment at 50°C for 10 minutes to inactivate the enzyme After drying in the oven, pass through a 100-mesh sieve. DHA-O / W emulsion, starch and water were mixed, heated by microwave at 500W for 5min, and the gel was filled with emulsion after cooling, the concentration of starch was 12.5wt%, and the concentration of oil phase was 12.5wt%.

[0031] Step 2) Prepare mixed low-fat milk: mix emulsion filling gel (5, 10, 15g), 10g of skim milk powder and water, pass through a 30MPa high-pressure homogenizer, and sterilize at 95±5°C for...

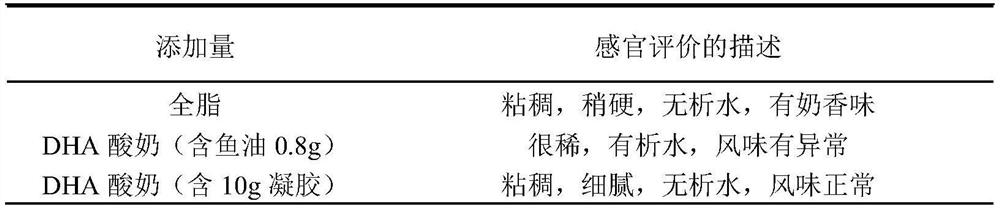

Embodiment 2

[0040] Step 1) Prepare emulsion filling gel: fish oil (DHA content 20%) and emulsifier are processed twice by homogenizer 30MPa to obtain DHA-O / W emulsion. Add water to the rice starch and put it into a vacuum packaging bag, shake it well, put it into an ultra-high pressure treatment device for 10 minutes of ultra-high pressure treatment at 400MPa, add a medium-temperature α-amylase at a ratio of 0.1% after treatment, and perform enzymatic hydrolysis treatment at 50°C for 10 minutes to inactivate the enzyme After drying in the oven, pass through a 100-mesh sieve. DHA-O / W emulsion, starch and water were mixed, heated by microwave at 500W for 5min, and after cooling, an emulsion-filled gel was obtained, the concentration of starch was 8wt%, and the concentration of oil phase was 8wt%.

[0041] Step 2) Prepare mixed low-fat milk: mix 10g of emulsion filling gel, 15g of skim milk powder and water, pass through a 30MPa high-pressure homogenizer, and sterilize at 95±5°C for 5 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com