High internal phase emulsion stabilized by using low-content surfactant, and preparation method of high internal phase emulsion

A technology of surfactant and high internal phase emulsion is applied in cosmetic preparations, chemical instruments and methods, medical preparations containing active ingredients, etc. Bright and lustrous color, wide source of raw materials, easy to apply effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The invention provides a method for preparing a high internal phase emulsion stable with grease ethoxylates, comprising the steps of:

[0031] (1) Weighing palm kernel oil ethoxylates with a mass fraction of 1.0%;

[0032] (2) Weigh soybean oil with a volume fraction of 74%;

[0033] (3) Mix the solutions in steps (1) and (2) at 15°C with a stirring speed of 3000rpm at a low speed;

[0034] (4) Accurately measure deionized water with a volume fraction of 26%;

[0035] (5) Add the water in step (4) dropwise to the mixture in step (3) at a stirring speed of 6000rpm;

[0036] (6) The dispersion system obtained in step (5) was homogenized with a high-shear dispersing emulsification homogenizer with a rotation speed of 10,000 rpm and a homogenization time of 10 minutes to obtain a high internal phase emulsion stabilized by palm kernel oil ethoxylate.

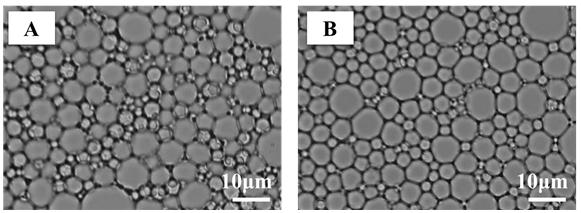

[0037] (7) In Example 1, a gradient test was carried out on the volume fraction of soybean oil in step (2), and the volum...

Embodiment 2

[0040] The invention provides a method for preparing a high internal phase emulsion stable with grease ethoxylates, comprising the steps of:

[0041] (1) Weighing rapeseed oil with a volume fraction of 83%;

[0042] (2) Weighing palm kernel oil ethoxylates with a mass fraction of 0.4% (wt%);

[0043](3) Mix the solutions in steps (1) and (2) at 25°C with a stirring speed of 3000rpm at a low speed;

[0044] (4) Accurately measure deionized water with a volume fraction of 17%;

[0045] (5) Add the water in step (4) dropwise to the mixture in step (3) at a stirring speed of 6000 rpm;

[0046] (6) The dispersion system obtained in step (5) was homogenized with a high-shear dispersing emulsification homogenizer with a rotation speed of 10,000 rpm and a homogenization time of 10 minutes to obtain a high internal phase emulsion stabilized by palm kernel oil ethoxylate.

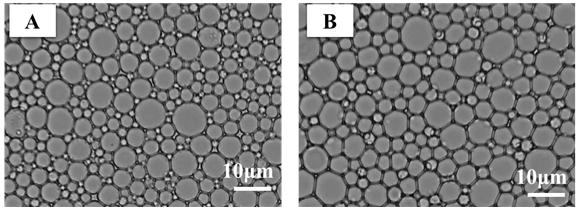

[0047] (7) In Example 2, a gradient test was carried out on the mass concentration of palm kernel oil ethoxylat...

Embodiment 3

[0050] The invention provides a method for preparing a high internal phase emulsion stable with grease ethoxylates, comprising the steps of:

[0051] (1) Weigh the grease ethoxylate with a mass fraction of 0.6% (wt%);

[0052] (2) Take coconut oil with a volume fraction of 83% (vol%);

[0053] (3) Mix the solutions in steps (1) and (2) at 30°C with a stirring speed of 3000rpm at a low speed;

[0054] (4) Accurately measure tertiary water with a mass fraction of 17%;

[0055] (5) Add the water in step (4) dropwise to the mixture in step (3) at a stirring speed of 6000rpm;

[0056] (6) Homogenize the dispersion system obtained in step (5) with a high-shear dispersing emulsification homogenizer with a rotation speed of 10,000 rpm and a homogenization time of 10 minutes to obtain a high internal phase emulsion with stable oil ethoxylates.

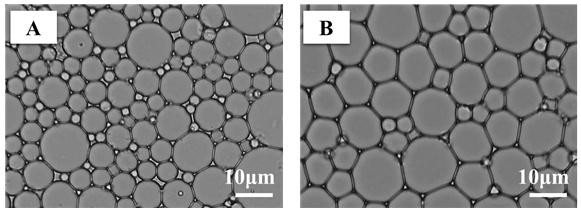

[0057] (7) In Example 3, the same series of oil ethoxylates in step (1) were tested, and the types were: coconut oil ethoxylates, palm kern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com