A sludge drying tail gas treatment system and process

A technology for tail gas treatment and sludge drying, which is applied in gas treatment, separation methods, and separation of dispersed particles, etc. It can solve the problems of secondary pollution of ozone, achieve the effects of short treatment route, increase contact time, and avoid secondary pollution of ozone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

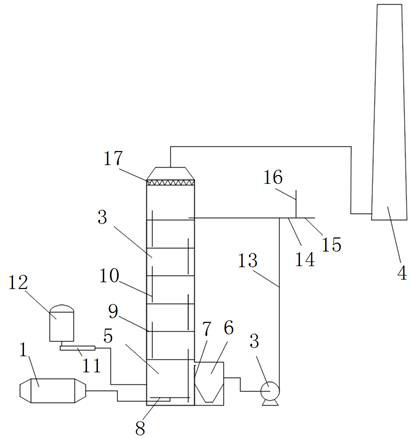

[0047] A sludge drying tail gas treatment system, such as figure 1 As shown, it includes a waste heat recovery device 1 , an exhaust gas treatment device 2 , a circulation pump 3 and an exhaust cylinder 4 . According to the flow direction of the sludge drying tail gas, the waste heat recovery device 1, the tail gas treatment device 2 and the exhaust pipe 4 are connected in sequence.

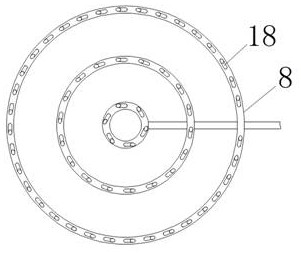

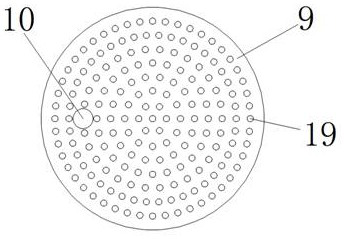

[0048] The tail gas treatment device includes a vertical tower body, a liquid storage tank 5 and an overflow chamber 6 are arranged at the bottom of the tower body, and an overflow plate 7 is arranged between the liquid storage tank 5 and the overflow chamber 6 . The bottom plate of the liquid storage tank 5 is provided with an aeration pan 8 , and the inlet of the aeration pan 8 is connected to the tail gas outlet of the waste heat recovery device 1 . Aeration discs, such as figure 2 As shown, it is formed by connecting several concentric annular pipes through the main pipe, and the pipe wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com