System and method for removing COD and calcium ions in cold rolling dilute alkali reverse osmosis concentrated water

A technology for reverse osmosis concentrated water and calcium ions, which is used in chemical instruments and methods, water pollutants, metallurgical wastewater treatment, etc. Difficulty in resource utilization and other problems, to achieve the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

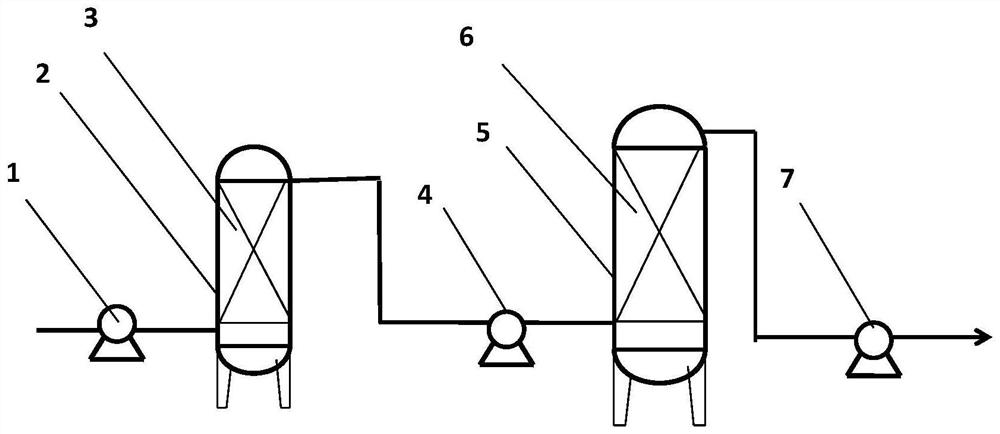

[0029] A cold-rolled dilute alkali reverse osmosis concentrated water treatment system, including a water inlet pump, a modified chitosan adsorption reaction tower, a modified chitosan-activated carbon mixed filler, a lift pump, a modified resin adsorption tower, and a modified chloromethyl Chemicalized polystyrene chelating resin, water pump. See figure 1 .

[0030] The water quality characteristics of the cold-rolled dilute alkali reverse osmosis concentrated water: the conductivity is 34500 μs / cm, the pH is 7.5, the COD is 55 mg / L, and the calcium ion is 65 mg / L.

[0031] The cold-rolled dilute alkali reverse osmosis concentrated water is pumped into the modified chitosan adsorption reaction tower from the bottom through the water inlet pump, and the modified chitosan-activated carbon mixed filler is placed in the modified chitosan adsorption reaction tower, and the water outlet is a modified chitosan adsorption reaction tower. The upper part of the chitosan adsorption re...

Embodiment 2

[0039] A cold-rolled dilute alkali reverse osmosis concentrated water treatment system, including a water inlet pump, a modified chitosan adsorption reaction tower, a modified chitosan-activated carbon mixed filler, a lift pump, a modified resin adsorption tower, and a modified chloromethyl Chemicalized polystyrene chelating resin, water pump.

[0040] The water quality characteristics of the cold-rolled dilute alkali reverse osmosis concentrated water: the electrical conductivity is 41200 μs / cm, the pH is 8.1, the COD is 41 mg / L, and the calcium ion is 52 mg / L.

[0041] The cold-rolled dilute alkali reverse osmosis concentrated water is pumped into the modified chitosan adsorption reaction tower from the bottom through the water inlet pump, and the modified chitosan-activated carbon mixed filler is placed in the modified chitosan adsorption reaction tower, and the water outlet is a modified chitosan adsorption reaction tower. The upper part of the chitosan adsorption reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com