Treatment method of denitration material in H acid production process

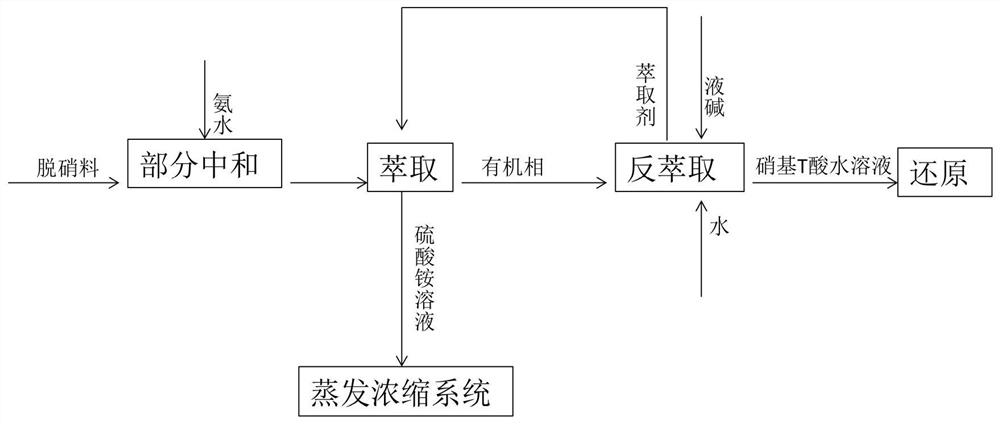

A technology of production process and treatment method, which is applied in the field of denitrification material treatment in the production process of H acid, can solve the problems of high requirements for extraction equipment, large loss of extraction agent, and low extraction efficiency, and achieve rapid and thorough stratification and low extraction agent loss. Small, the effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

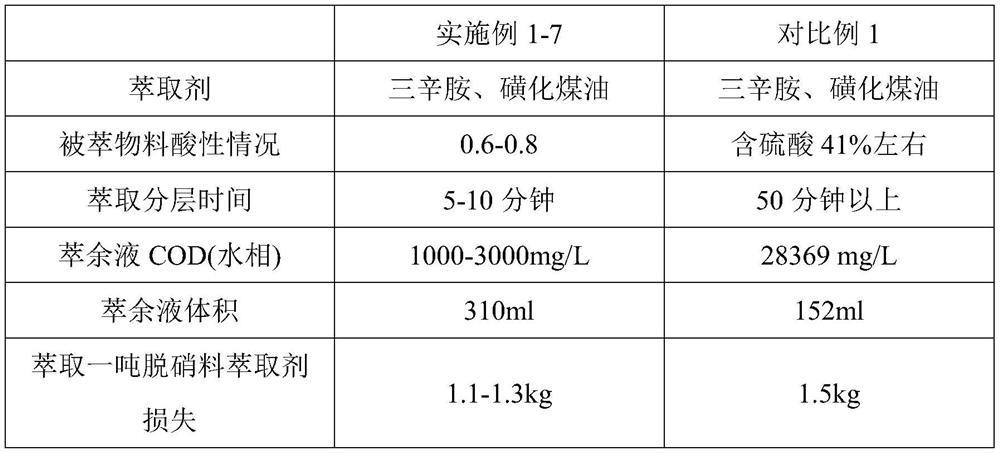

Embodiment 1

[0029] (1) Neutralization: Add 400g of liquid denitrification material into a 1000ml beaker, neutralize it with 18% ammonia water, and cool it with ice water at the same time, control the temperature at about 60°C, and neutralize until the final pH value is 0.7.

[0030] (2) Preparation of extractant: According to the molar ratio of nitro-T acid and trioctylamine in the denitration material is 1:3.6, the mass ratio of trioctylamine and sulfonated kerosene in the extractant is 1:1, and the 2L glass Add 510 g of trioctylamine and 510 g of sulfonated kerosene into the reaction kettle, start stirring and mixing evenly.

[0031] (3) Extraction: put the neutralized denitrification material into a 2L glass reactor, raise the temperature to 60°C, stir for 0.5 hour, then let it stand for 20 minutes, and separate the lower aqueous phase ammonium sulfate aqueous solution.

[0032] (4) Stripping: Add 30% aqueous sodium hydroxide solution and 260 g of water to a 2L glass reactor, adjust th...

Embodiment 2

[0035] The neutralizing pH value of step (1) of embodiment 1 is adjusted to 0.6, and all the other steps are consistent with embodiment 1.

[0036] As a result, in the extraction step, good stratification without entrainment can be achieved after standing for 5 minutes; after conversion of the loss of extractant, the loss of extractant per ton of denitrification material is 1.2kg.

Embodiment 3

[0038] The neutralizing pH value of step (1) of embodiment 1 is adjusted to 0.8, and all the other steps are consistent with embodiment 1.

[0039] As a result, in the extraction step, good stratification without entrainment can be achieved by standing still for 8 minutes; after conversion of the extraction agent loss, the loss of extraction agent per ton of denitrification material is 1.2kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com