A kind of method for sludge resource treatment

A sludge treatment and recycling technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of breeding stock disturbance, waste of resources, etc., and reduce bad impact, reduce turbidity, and realize the effect of resource treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for sludge resource treatment, comprising the steps of:

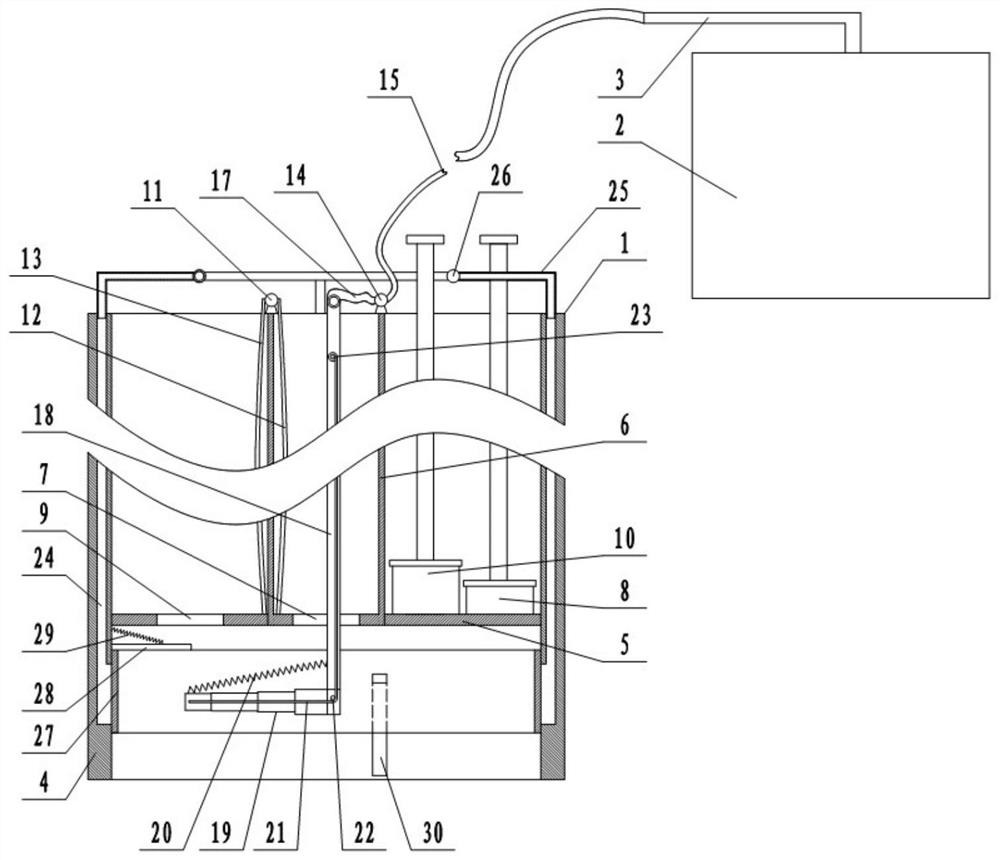

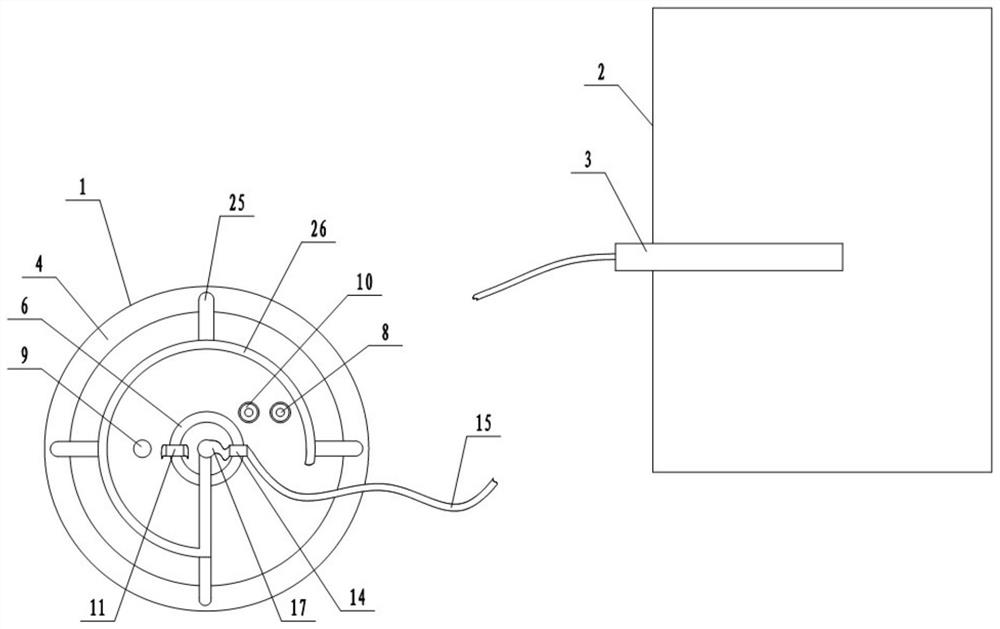

[0041] Step 1: Prepare the sludge treatment system: combine the attached figure 1 and attached figure 2 As shown, the sludge treatment system includes a sludge extraction device 1, a sludge flocculation device 2 and a connecting pipe 3 for connecting the sludge extraction device 1 and the sludge flocculation device 2. The sludge extraction device 1 is mainly composed of a partition cylinder 4 , a partition plate 5, an inner cylinder 6, a first sealing plug 8, a second sealing plug 10, a water pumping unit, and a first extraction unit. The bottom of the partition cylinder 4 is welded with a partition plate 5 made of transparent material. The separation plate 5 is 8-10 cm away from the bottom end of the separation cylinder 4 . The partition plate 5 divides the partition cylinder 4 into a pool water part and a sludge part, and the pool water part is located above the sludge part. The inner cylinder 6 is...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that the sludge treatment system in step 1 further includes a second extraction unit, which is arranged on the separating cylinder 4 and is used to assist in extracting sludge. combined with figure 1 and attached figure 2 As shown, the second extraction unit is mainly composed of several pipe holes 24, several branch pipes 25, and a confluence pipe 26. Several pipe holes 24 are evenly distributed in the side wall of the separating cylinder 4 and are arranged longitudinally. L-shaped, branch pipes 25 are fixedly installed on the top of the pipe hole 24, all the branch pipes 25 are connected with a confluence pipe 26, and the confluence pipe 26 is communicated with the rigid section 18 of the mud inlet pipe; the bottom opening of the pipe hole 24 is set at a distance from The bottom 1-3 cm of the cylinder body 4 is separated and communicated with the sludge part. The sludge part is provided with a sealing unit f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com