Light-cured urethane acrylate resin composition and preparation method and application thereof

A technology of urethane acrylate and resin composition, which is applied in the field of light-curing urethane acrylate resin composition and its preparation, can solve the problems of not meeting the requirements for the use of synthetic leather, low elongation at break, and low tensile strength, and achieve The effect of reducing the cost and difficulty of resin preparation process, improving mechanical properties and high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

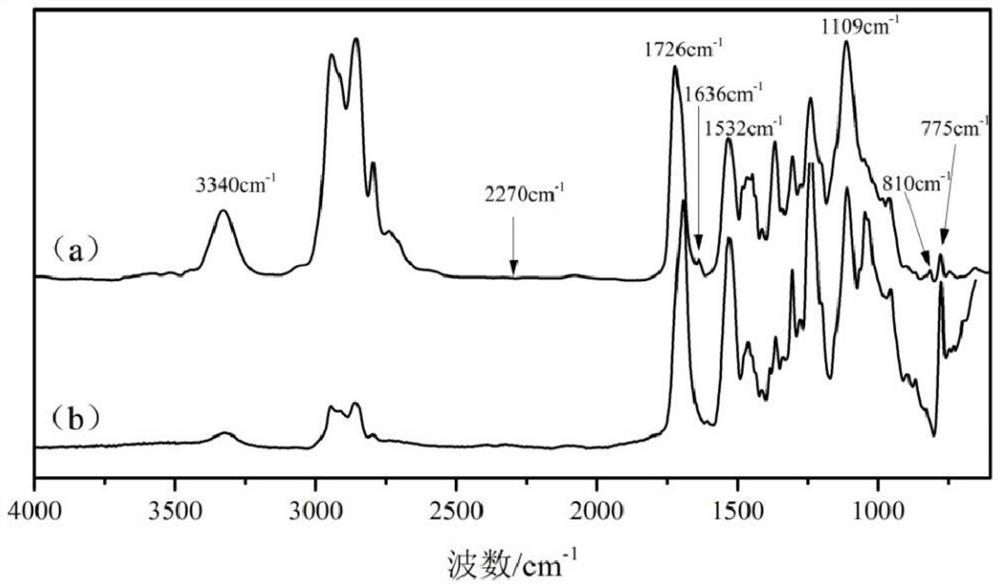

Image

Examples

Embodiment 1

[0119] Add 100 parts of polytetrahydrofuran ether diol with a number average molecular weight of 1000 into the reaction kettle, dehydrate at 110°C for 2 hours, then cool down to 50°C, add 7.5 parts of ethylene glycol, 60 parts of isophorone diisocyanate, 15 parts of ethylene Oxyethoxyethyl acrylate, heat up to 80°C for 2 hours, then cool down to 50°C, then add 0.1 parts of dibutyltin dilaurate (DBTDL) and 10.5 parts of hydroxyethyl acrylate to the reaction kettle, heat up to 80°C , reacted for 3 hours, stopped the reaction and lowered the temperature to obtain the polyurethane acrylate resin composition, based on the total weight of the composition, the content of the reactive diluent was 7.77wt%.

[0120] After calculation, the total content of the first hard segment and the second hard segment is 37.91wt%. In the polyurethane acrylate resin, the content of the first hard segment is 33.7wt%, the content of the second hard segment is 4.21wt%, the content of the soft segment is...

Embodiment 2

[0124] Add 100 parts of polytetrahydrofuran ether diol with a number average molecular weight of 1000 into the reactor, dehydrate at 120°C for 2 hours, then cool down to 50°C, add 11 parts of propylene glycol, 70 parts of 4,4'-dicyclohexylmethane diisocyanate, 20 parts of cyclotrimethylolpropane formal acrylate, heat up to 80°C for 2 hours, then cool down to 50°C, then add 0.1 parts of dibutyltin dilaurate and 8.2 parts of caprolactone-modified formaldehyde into the reaction kettle Acrylate, heated to 80 ° C, reacted for 3 hours, stopped the reaction, lowered the temperature to obtain the polyurethane acrylate resin composition, based on the total weight of the composition, the content of the reactive diluent was 9.56wt%.

[0125] After calculation, the total content of the first hard segment and the second hard segment is 42.81wt%. In the polyurethane acrylate resin, the content of the first hard segment is 37wt%, the content of the second hard segment is 5.81wt%, the content...

Embodiment 3

[0127] Add 200 parts of polytetrahydrofuran ether diol with a number average molecular weight of 2000 into the reaction kettle, dehydrate in vacuum at 110°C for 2 hours, then cool down to 50°C, add 41 parts of 1,4-butanediol, 160 parts of isophorone diol Isocyanate, 25 parts of ethoxyethoxyethyl acrylate, heat up to 80 ° C for 2 hours, then cool down to 50 ° C, then add 0.1 part of dibutyltin dilaurate to the reaction kettle, add 46.8 parts of hydroxyethyl methacrylate ester, heated to 80° C., reacted for 3 hours, stopped the reaction, and lowered the temperature to obtain the polyurethane acrylate resin composition. Based on the total weight of the composition, the content of the reactive diluent was 5.27 wt%.

[0128] After calculation, the total content of the first hard segment and the second hard segment is 44.89wt%. In the polyurethane acrylate resin, the content of the first hard segment is 35.73wt%, the content of the second hard segment is 9.16wt%, the content of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com