Method and device for measuring lithium pre-intercalation amount of lithium ion battery negative electrode

A technology of lithium-ion batteries and pre-embedded lithium, which is applied in the field of lithium-ion batteries, can solve problems affecting battery performance, achieve simple operation, and ensure the effect of battery production and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

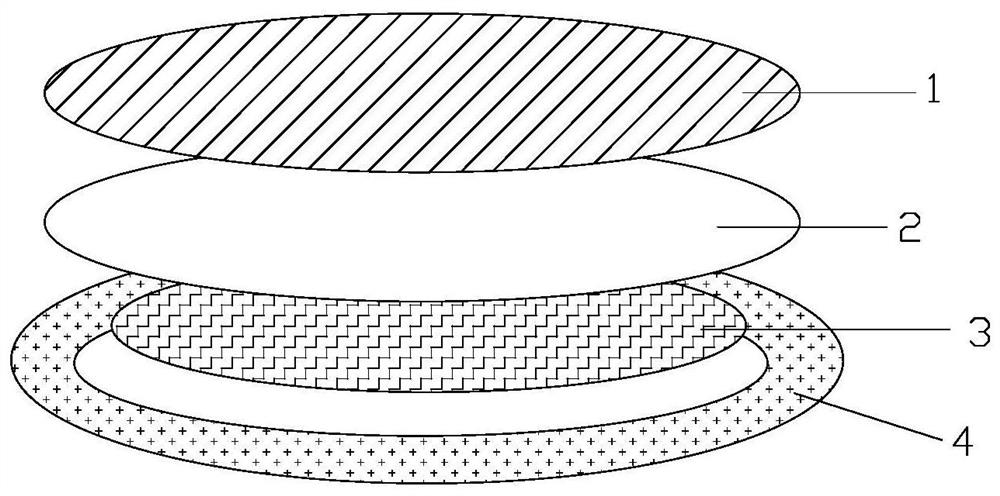

[0038] The embodiment of the present invention provides a device for measuring the amount of pre-embedded lithium in the negative electrode of a lithium-ion battery. A lithium sheet with a thickness ≥ 50 μm is used as a counter electrode 1, a silicon oxygen carbon negative electrode is a working electrode 3, and a lithium-rich manganese-based solid solution positive electrode is used as a reference electrode. 4. Diaphragm 2 adopts polyolefin diaphragm, and is assembled according to the sequence of counter electrode 1, diaphragm 2, working electrode 3 and reference electrode 4 as follows: figure 1 In the structure shown, the counter electrode 1 and the diaphragm 2 are attached to each other, the working electrode 3, the reference electrode 4 and the diaphragm 2 are also attached, and the reference electrode 4 is in the shape of a ring, which is in the same position as the working electrode 3. On a horizontal plane but without contact, the outer radius of the ring of the referenc...

Embodiment 2

[0040] The embodiment of the present invention provides a method for measuring the amount of pre-intercalated lithium in the negative electrode of a lithium-ion battery, and the specific steps are as follows:

[0041] 1) The silicon oxygen carbon negative electrode is used as the working electrode, the lithium sheet with a thickness ≥ 50 μm is used as the counter electrode, the lithium-rich manganese-based solid solution positive electrode is used as the reference electrode, and the diaphragm is made of polyolefin diaphragm, such as figure 1 The three-electrode structure shown;

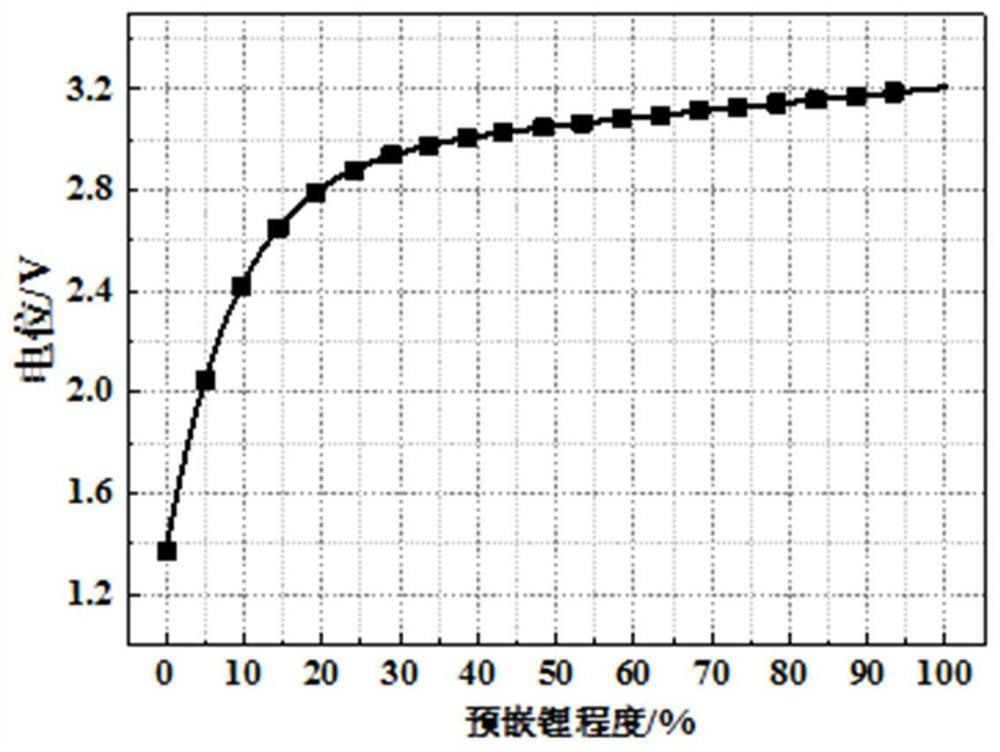

[0042] 2) Use an electrochemical workstation or a charge-discharge tester to perform lithium intercalation on the silicon oxygen carbon negative electrode working electrode with a constant current titration method for every 1-10% of the electricity, and the relaxation time is ≥ 10 hours, and record the silicon oxygen carbon negative electrode working electrode and The potential between the lithium-ric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com