Preparation method of self-cleaning coating on surface of light-induced solar cell

A self-cleaning coating and solar cell technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as not making full use of direct sunlight conditions, and achieve the effect of saving raw materials and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

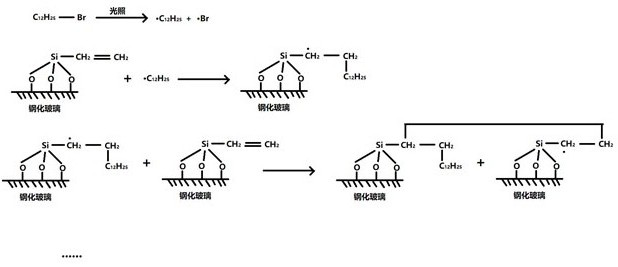

[0023] The hydrophobic coating of the solar cell panel is constructed under the ultraviolet light, and the sunlight induces the radical reaction of the halogenated alkanes, and directly polymerizes on the surface of the solar cell to obtain a hydrophobic coating, which is constructed according to the following steps:

[0024] (1) Construction of vinyl coating:

[0025] Disperse 0.3 mL of silane coupling agent A151 in 30 mL of water to obtain a 1% aqueous solution of silane coupling agent at room temperature, add 5 drops of 25% concentrated ammonia water and stir rapidly for 1 h until a uniform liquid is formed;

[0026] (2) Apply the above liquid on the surface of the solar panel, drain and recycle the excess liquid, and let it dry in the dark at room temperature for 1 hour until the coating is initially dry. This step should avoid direct sunlight;

[0027] (3) Coating 1-bromododecane:

[0028] 1) Dissolve 1 mL of 1-bromododecane in 30 mL of ethyl acetate;

[0029] 2) Add th...

Embodiment 2

[0034] Construct the solar cell panel hydrophobic coating under direct sunlight, similar to Example 1, construct according to the following steps:

[0035] (1) Construction of vinyl coating:

[0036] Disperse 0.3 mL of silane coupling agent A151 in 30 mL of water at room temperature, add 5 drops of 25% concentrated ammonia water dropwise and stir rapidly for 1 h until a uniform liquid is formed;

[0037] (2) Add the above liquid onto the surface of the solar panel and spread it evenly with a non-woven fabric, drain and recover the excess liquid, and let it dry in the dark at room temperature for 1 hour until the coating is initially dry;

[0038] (3) Coating 1-bromohexadecane:

[0039] 1) Dissolve 1 mL of 1-bromohexadecane in 30 mL of ethyl acetate;

[0040] 2) Add the solution obtained in step 1) onto the surface of the solar panel and spread it evenly with a plastic spatula, drain and recover the excess liquid, and let it stand for 0.5 h until the ethyl acetate in the coat...

Embodiment 3

[0045] Under the ultraviolet light, dibromoalkane is used to construct the solar panel hydrophobic coating, which is similar to Example 1, and is constructed according to the following steps:

[0046] (1) Construction of vinyl coating:

[0047]Disperse 0.3 mL of silane coupling agent A151 in 30 mL of water at room temperature, add 5 drops of 25% concentrated ammonia water and stir rapidly for 1 h until a uniform liquid is formed;

[0048] (2) Add the above liquid onto the surface of the solar panel and spread it evenly with a non-woven fabric, drain and recover the excess liquid, and let it dry in the dark at room temperature for 1 hour until the coating is initially dry. This step needs to avoid sunlight Direct;

[0049] (3) Coating 1,6-dibromohexane:

[0050] 1) Dissolve 1 mL of 1,6-dibromohexane in 30 mL of petroleum ether;

[0051] 2) Add the solution obtained in step 1) onto the surface of the solar panel and spread it evenly with a plastic scraper, drain and recover t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com