Process for comprehensively utilizing biomass energy in plant stems

A biomass energy and stem technology, which is applied in the field of biomass energy comprehensive utilization process, can solve the problems of unfavorable small-scale enterprises putting into use, large floor space, complex structure, etc., and achieves ingenious and simple structure, high degree of automation, Easy to collect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

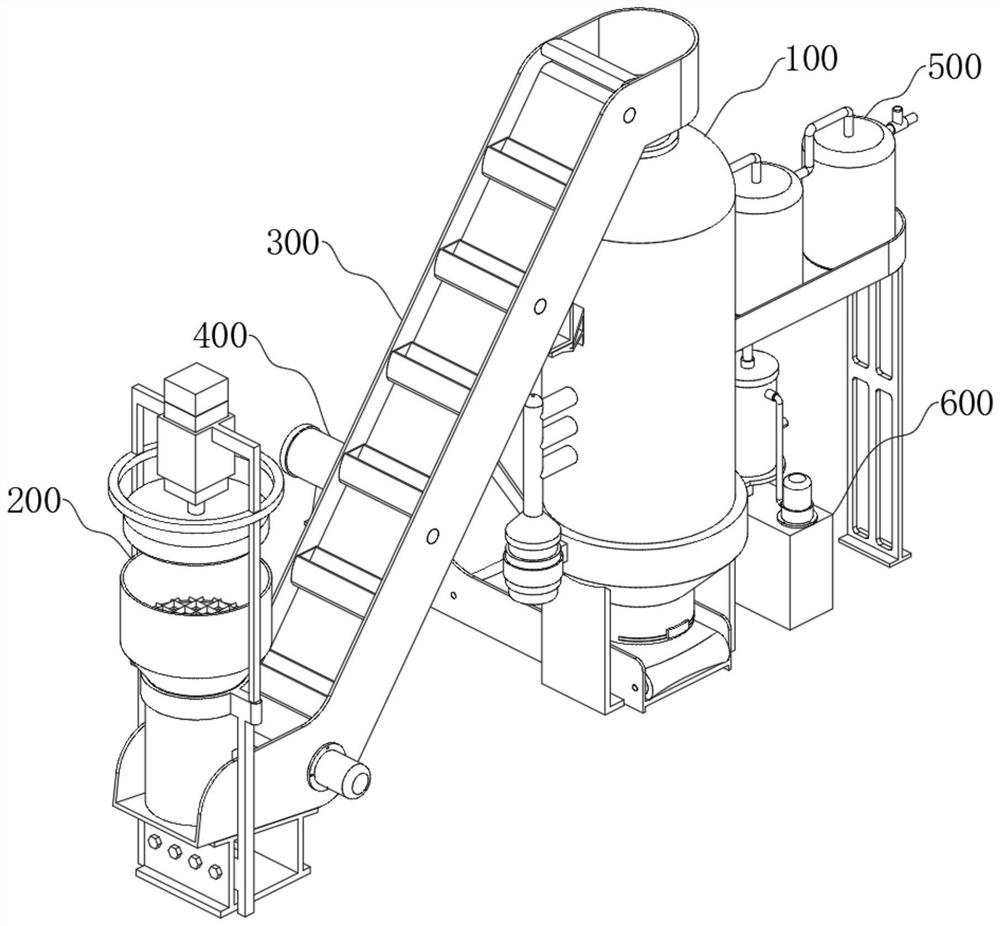

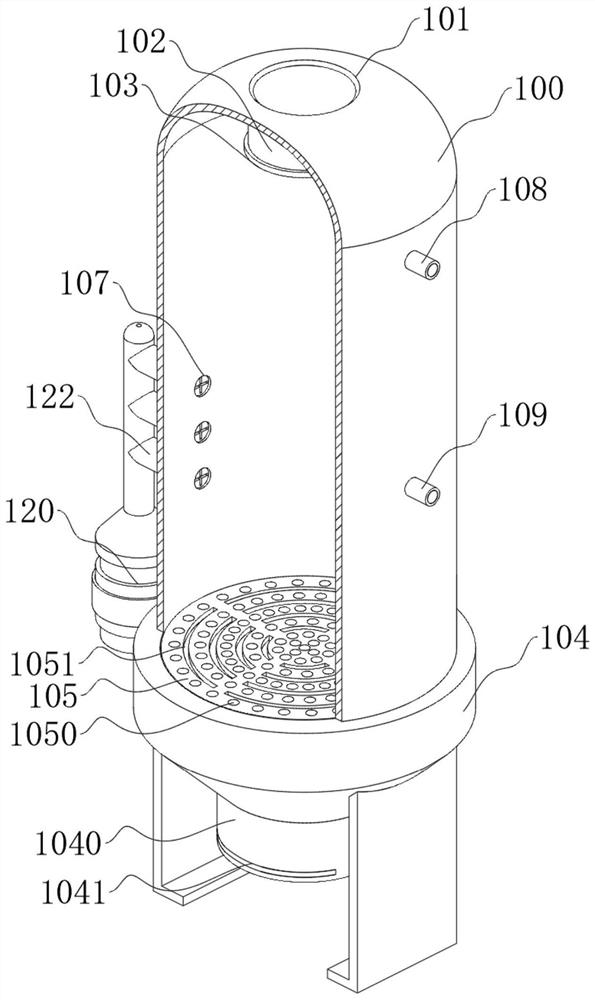

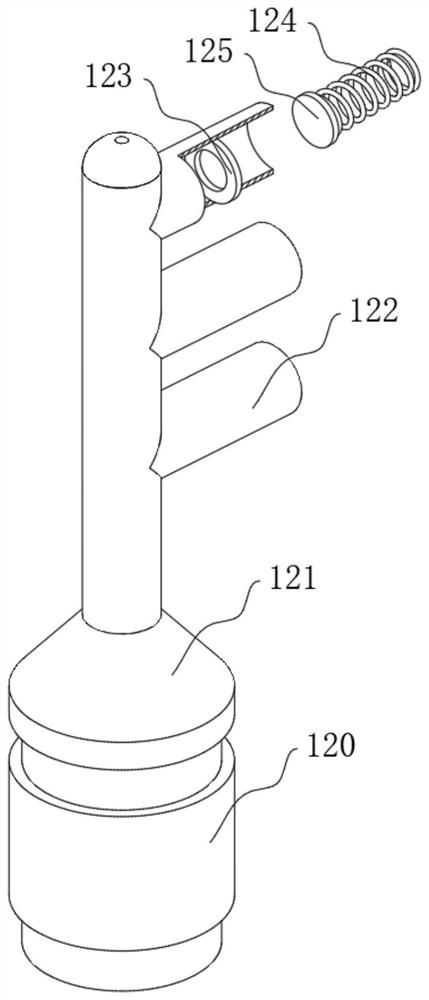

[0081] The invention provides a process for comprehensive utilization of biomass energy in plant stems, which comprises the following steps:

[0082] 1. Plant stem crushing stage:

[0083] S1, first put the plant stems into the crushing box 210 until it is almost full;

[0084] S2. Restart the electric cylinder 230 to make it work, and drive its piston rod to extend, and then drive the crushing block 220 to enter the crushing box 210 to squeeze the plant stem, which is cut and broken by the cutting rod 2110 and falls;

[0085] S3. After all the plant stems in the crushing box 210 are extruded, start the electric cylinder 230 to make it work, drive the crushing block 220 to reset, then put the plant stems in, and continue crushing according to the above steps;

[0086] 2. Plant stem transportation stage:

[0087] S4. The crushed plant stems fall into the collection platform 320 for accumulation, then start the conveying motor 360 to drive the conveyor belt 340 to circulate in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com