A kind of method for synthesizing nanometer cu-mof bacteriostatic agent in aqueous phase

A kind of bacteriostatic agent, nanotechnology, applied in the field of water-phase synthesis of nano-Cu-MOF bacteriostatic agent, can solve the problem of difficult scale expansion, achieve the effect of enhanced bacteriostatic rate, wide application value, and inhibition of bacterial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

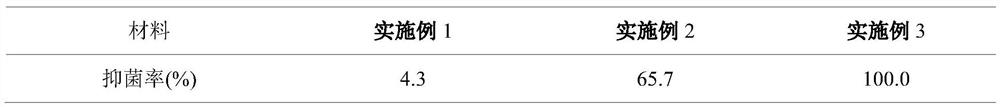

Embodiment 1

[0036] (1) At room temperature, betaine was dissolved in 10mL water, stirred to obtain a clear solution, and the mass fraction of the resulting aqueous solution was 3%;

[0037] (2) Put copper nitrate hexahydrate and zirconium chloride into the solution obtained in step (1) in a molar ratio of 0:10 respectively, stir until completely dissolved, then add 2-aminoterephthalic acid powder, chlorinate The molar ratio of zirconium to 2-aminoterephthalic acid is 1:1, stir for 1h until uniform;

[0038] (3) Put the suspension in step (2) in a 20mL hydrothermal kettle, react in a constant temperature oven at 110°C for 24h, wash the obtained product with deionized water, centrifuge 3 times at 8000r / min, and dry it in vacuum at 60°C for 24h. Obtain Cu-MOF powder.

Embodiment 2

[0040] (1) At room temperature, cocamidopropyl betaine was dissolved in 10mL water, stirred to obtain a clear solution, and the mass fraction of the resulting aqueous solution was 8%;

[0041] (2) Put copper nitrate hexahydrate and zirconium chloride into the solution obtained in step (1) at a molar ratio of 1:4 respectively, stir until completely dissolved, then add 2-aminoterephthalic acid powder, hexahydrate The total substance amount of copper nitrate and zirconium chloride is 1:2 with the molar ratio of 2-aminoterephthalic acid, and stirs for 1h until uniform;

[0042] (3) Put the suspension in step (2) in a 20mL hydrothermal kettle, react in a constant temperature oven at 110°C for 24h, wash the obtained product with deionized water, centrifuge 3 times at 8000r / min, and dry it in vacuum at 60°C for 24h. Obtain Cu-MOF powder.

Embodiment 3

[0044] (1) At room temperature, dissolve betaine in 10mL water, stir to obtain a clear solution, and the mass fraction of the resulting aqueous solution is 10%;

[0045] (2) Put copper nitrate hexahydrate and zirconium chloride into the solution obtained in step (1) at a molar ratio of 10:0 respectively, stir until completely dissolved, then add 2-aminoterephthalic acid powder, hexahydrate The molar ratio of copper nitrate to 2-aminoterephthalic acid is 1:3, stir for 1h until uniform;

[0046] (3) Put the suspension in step (2) in a 20mL hydrothermal kettle, react in a constant temperature oven at 110°C for 24h, wash the obtained product with deionized water, centrifuge 3 times at 8000r / min, and dry it in vacuum at 60°C for 24h. Obtain Cu-MOF powder.

[0047] The specific experimental analysis is given below.

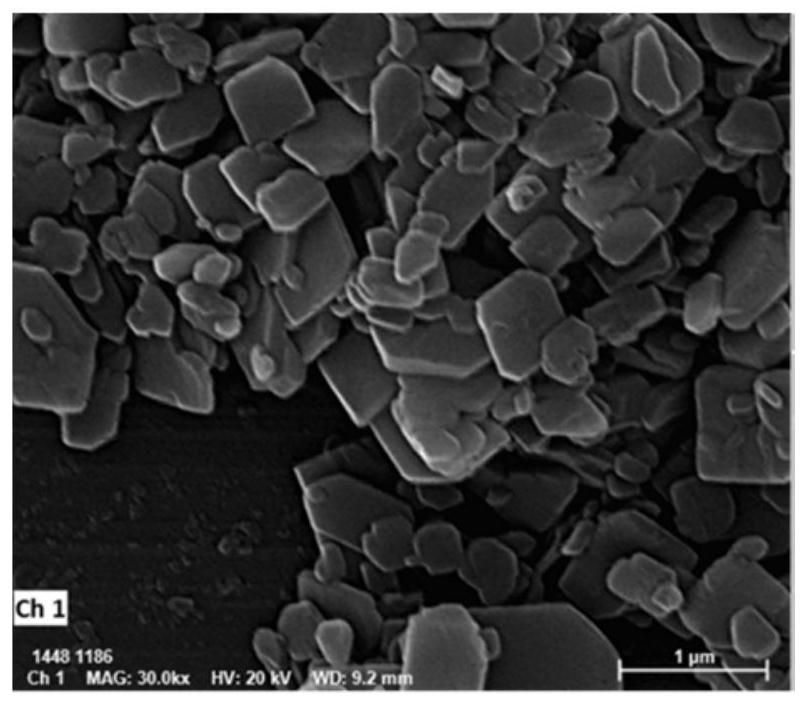

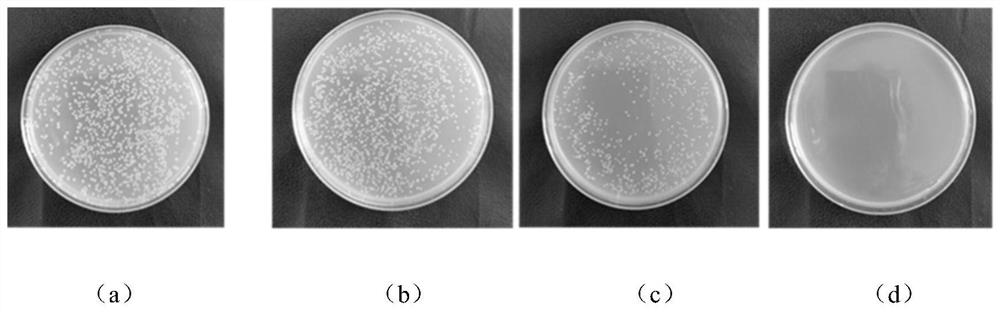

[0048] (1) Morphology and elemental analysis

[0049] By scanning electron microscope (model is MAIA3, Tescon company) carries out morphological characterization to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com