Making process of instantly brewed instant rice

A technology of instant rice and production process, applied in the field of food processing, can solve the problems of uncontrollable taste, increased production cost, and high cost, and achieves the effect of ensuring shape, taste, color, color and density, and easy extrusion molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

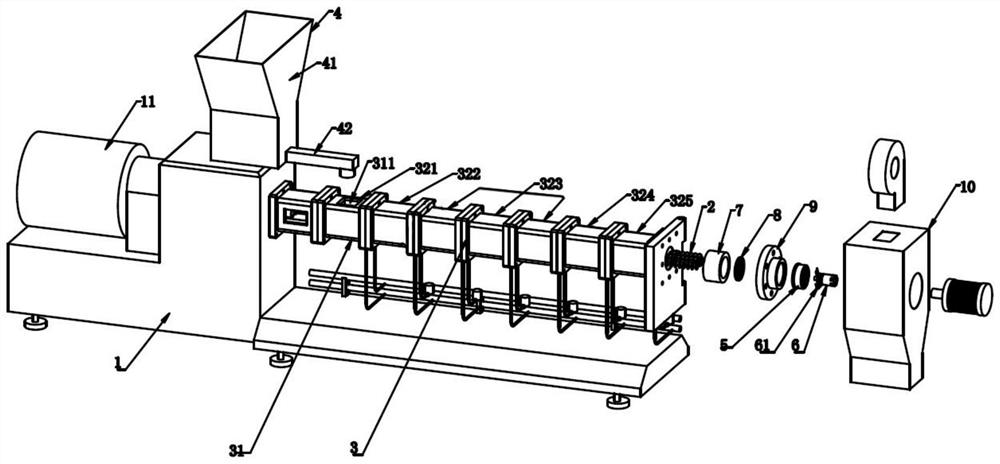

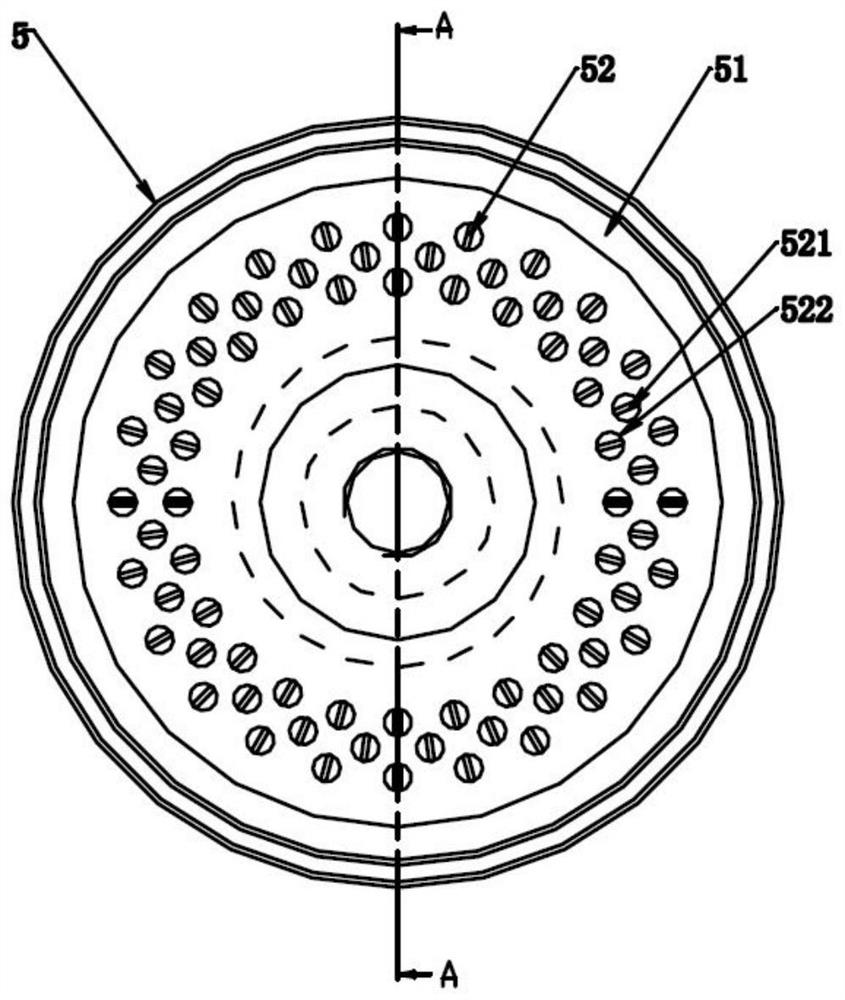

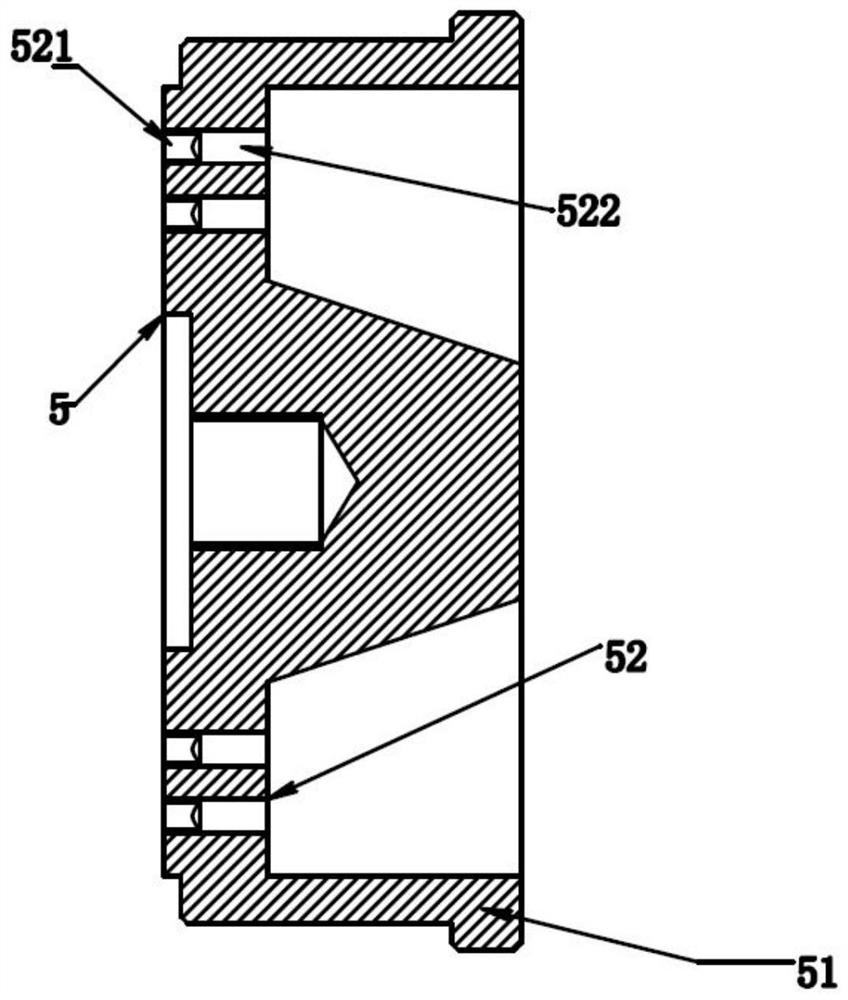

[0039] The process for making instant hot rice prepared by brewing in the present invention adopts the following equipment, such as a grain raw material screening machine, a grain raw material grinder, a grain raw material mixing mixer, an extruder, drying, cooling and packaging equipment, and the like.

[0040] The preparation technology of the instant rice of instant brewing of the present invention comprises the following steps:

[0041] A) Screening of grain raw materials: remove the sundries in the grain raw materials through screening equipment;

[0042] B) Crushing of grain raw materials: use a pulverizer to pulverize the grain raw materials into powders with a particle size not greater than 1 mm; 0.8mm powder with sufficient fineness is required. If the powder is too thick, it will not be easy to form during extrusion, and the finished rice grains after extrusion will have a rough taste. If the powder is too fine, although it is easy to stick when extruded, the feedi...

Embodiment 2

[0060] The difference between this example and Example 1 is that the drying step uses a fluidized bed for drying, the temperature of the fluidized bed drying is 100°C to 160°C, and the water content in the prepared rice grains is 11 % to 14%, because the drying speed of the fluidized bed is not as fast as that of microwaves, and the penetration is not as good as microwave heating, so the drying effect is ensured by increasing the drying temperature, and the drying temperature of the fluidized bed is controlled within this range. It not only ensures the rapid dehydration and drying of the extruded rice grains, but also supplements the aging effect, so as to ensure the water content of the prepared rice grains, and also ensures that the color of the dried rice remains unchanged and the brightness is sufficient. In this embodiment, the drying temperature is such that the water content in the prepared rice grains is 11.5%, thus ensuring the rehydration and mouthfeel of the rice dur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com