Raw flue gas dechlorinating device for wet desulphurization system

A wet desulfurization, raw flue gas technology, applied in gas treatment, separation methods, chlorine/hydrogen chloride, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

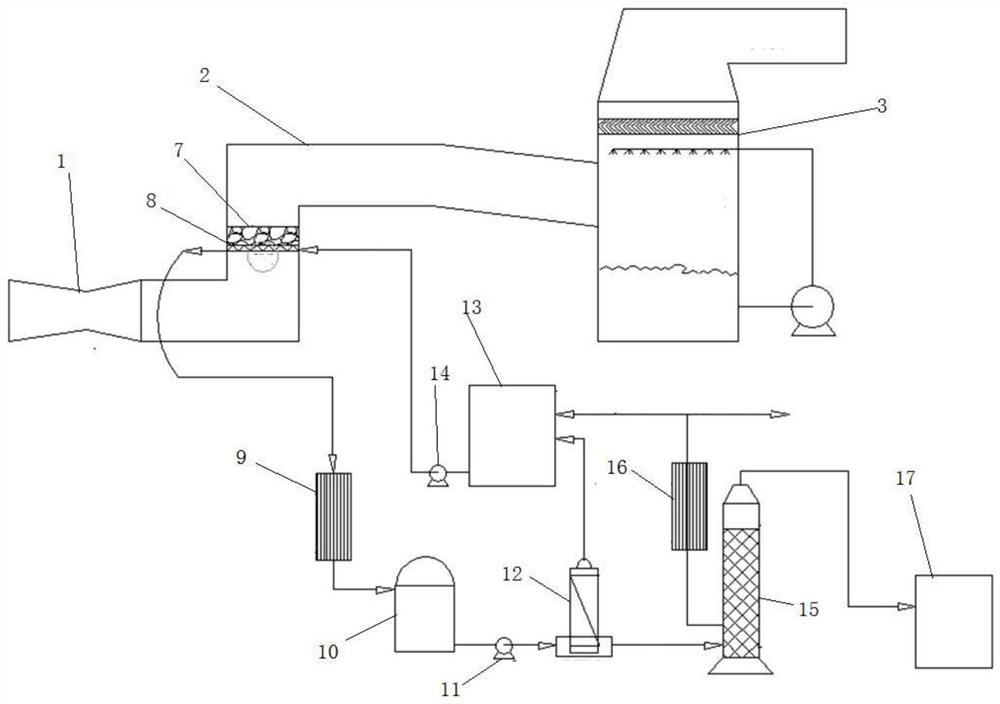

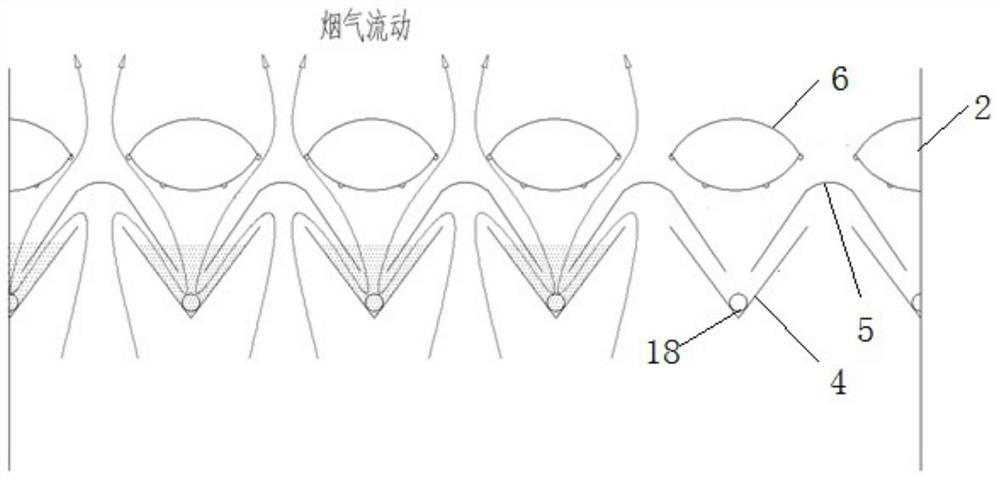

[0019] The present invention is a kind of raw flue gas dechlorination device used in wet desulfurization system, such as figure 1 As shown, including fan 1, fan 1 is connected to the entrance of desulfurization absorption tower 3 through the original flue 2, the original flue 2 is an L-shaped flue, the vertical flue section of the original flue 2 is connected to the outlet of the fan 2, and the original In the vertical flue section of channel 2, there is an HCl absorbing device horizontally. The HCl absorbing device includes a packing layer 7 and an absorbing layer 8 arranged up and down. The absorbing layer 8 includes defogging pipes 6 arranged horizontally in sequence. The two ends of 6 are fixed on the inner wall of the original flue 2. The cross-section of the defogging pipe 6 is an egg-shaped structure. There are four raised droplet barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com