Preparation method of chitosan modified desulfurization adsorbent and application of chitosan modified desulfurization adsorbent in transformer oil treatment

A chitosan modification and adsorbent technology, applied in the direction of selective adsorption, chemical instruments and methods, ion exchange treatment devices, etc., can solve the problems of complex production and preparation methods, high production costs, poor use effects, etc., and achieves improved decolorization. Desulfurization effect, low production cost, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

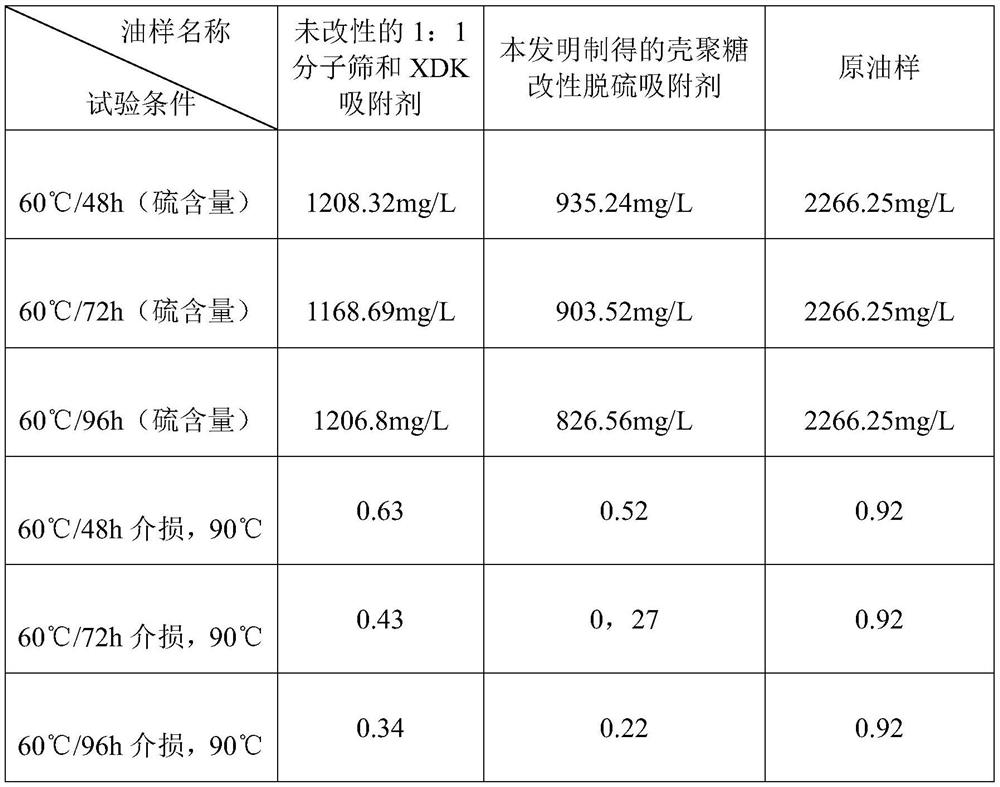

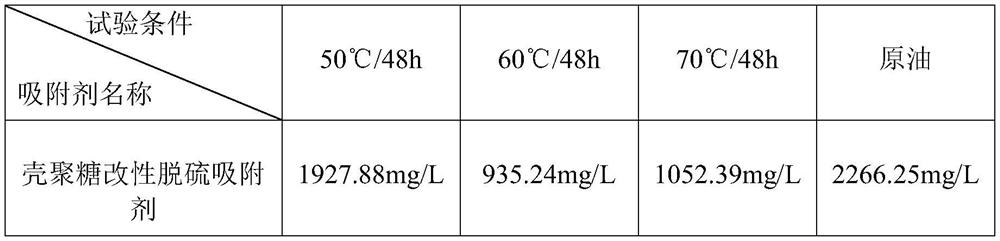

Examples

Embodiment 1

[0020] A preparation method of a chitosan modified desulfurization adsorbent, comprising the steps of:

[0021] (1) Preparation of intermediate hydroxypropyltrimethylammonium chloride: Add concentrated HCl dropwise to trimethylamine at 4°C to react to generate trimethylamine hydrochloride, add epichlorohydrin at 31°C after 10 minutes, and then Stir and heat to 51°C, slowly add NaOH solution dropwise after 1h, make trimethylamine hydrochloride slowly decompose trimethylamine and react with epichlorohydrin to form glycidyltrimethylammonium chloride, continue stirring for 2h, and finally depressurize Distillation obtains hydroxypropyltrimethylammonium chloride, wherein the mass ratio of trimethylamine and epichlorohydrin added is: 1:1.5;

[0022] (2) Preparation of nano-copper-loaded adsorbent: according to the mass ratio of 1:1, respectively take molecular sieves with a pore size of 3-5nm and an XDK sorbent with a pore size of 5-15nm, and add them to a copper nitrate solution wi...

Embodiment 2

[0027] A preparation method of a chitosan modified desulfurization adsorbent, comprising the steps of:

[0028] (1) Preparation of intermediate hydroxypropyltrimethylammonium chloride: Add concentrated HCl dropwise to trimethylamine at 5°C to generate trimethylamine hydrochloride, add epichlorohydrin at 25°C after 10 minutes, and then Stir and heat to 55°C, slowly add NaOH solution dropwise after 1h, make trimethylamine hydrochloride slowly decompose trimethylamine and react with epichlorohydrin to form glycidyltrimethylammonium chloride, continue stirring for 2h, and finally depressurize Distillation obtains hydroxypropyltrimethylammonium chloride, wherein the mass ratio of trimethylamine and epichlorohydrin added is: 1:2;

[0029] (2) Preparation of nano-copper-loaded adsorbent: according to the mass ratio of 1:1, take the molecular sieve with a pore size of 3-5nm and the XDK sorbent with a pore size of 5-15nm, and add them to a copper nitrate solution with a mass fraction o...

Embodiment 3

[0034] A preparation method of a chitosan modified desulfurization adsorbent, comprising the steps of:

[0035] (1) Preparation of intermediate hydroxypropyltrimethylammonium chloride: add 100 grams of 5mol / L concentrated HCl dropwise to 100 grams of 6mol / L trimethylamine at 3°C to generate trimethylamine hydrochloride, and after 10 min Add epichlorohydrin at 20°C, stir and heat to 55°C, and slowly add 0.5mol / L NaOH solution dropwise after 1 hour, so that trimethylamine hydrochloride slowly decomposes into trimethylamine and reacts with epichlorohydrin to form glycidol Trimethylammonium chloride, continue stirring for 2h, and finally obtain hydroxypropyltrimethylammonium chloride by distillation under reduced pressure, wherein the mass ratio of trimethylamine and epichlorohydrin added is: 1:3;

[0036] (2) Preparation of nano-copper-loaded adsorbent: according to the mass ratio of 1:1, take 100 grams of XDK adsorbent with a pore size of 3-5 nm and a pore size of 5-15 nm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com