High-weatherability ceramic tile binder, and preparation method and construction method thereof

A ceramic tile adhesive, high weather resistance technology, applied in chemical instruments and methods, inorganic chemistry, construction and other directions, can solve the problems of weather resistance, poor freeze-thaw resistance, prone to gaps, tiles falling off, etc. High adhesive strength, reducing caking, and the effect of solid tile bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

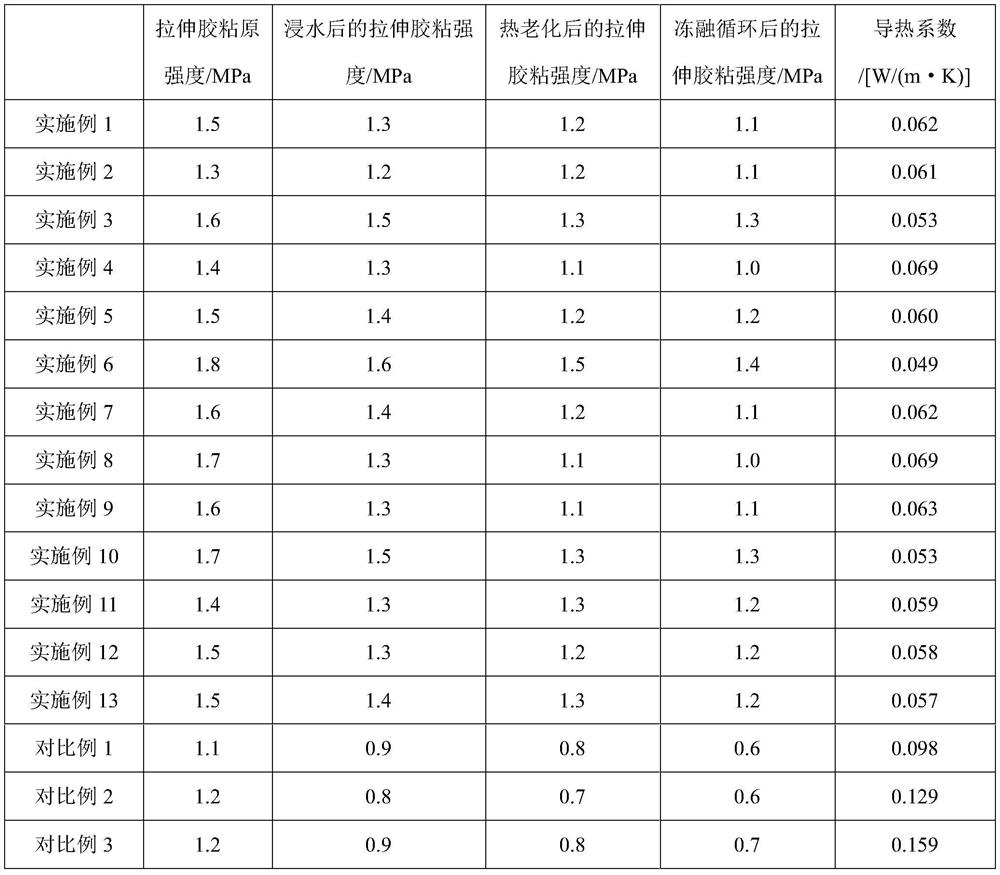

Examples

preparation example 1

[0051] A highly weather-resistant tile adhesive, the preparation steps of modified silica airgel are:

[0052] 1) Sol-gel process: Mix 20kg of tetraethylorthosilicate, 12kg of octyltrimethoxysilane, 80kg of absolute ethanol, and 8kg of deionized water, stir with ultrasonic vibration at 55°C for 30min, and add 30% mass fraction ammonia water to adjust the pH value to 8.5, and continue to ultrasonically oscillate and stir for 2.5 hours to form a mixed solution a of the modified silica wet gel and the solution;

[0053] 2) Aging of the gel: The mixed solution a was left to stand for 45 hours. During the standing process, the solution was continuously discharged slowly, and absolute ethanol was slowly introduced, so that the modified silica wet gel was completely immersed in the absolute ethanol to form Mixture b of modified silica alcohol gel and ethanol;

[0054] 3) Drying of the gel: drying the mixed solution b under supercritical conditions to obtain a hydrophobic modified si...

preparation example 2

[0056] A highly weather-resistant tile adhesive, the preparation steps of modified silica airgel are:

[0057] 1) Sol-gel process: Mix 25kg of tetraethylorthosilicate, 15kg of octyltrimethoxysilane, 75kg of absolute ethanol, and 10kg of deionized water, stir with ultrasonic vibration at 60°C for 35min, and add 30% mass fraction ammonia water to adjust the pH value to 8.0, and continue to ultrasonically oscillate and stir for 2 hours to form a mixed solution a of the modified silica wet gel and the solution;

[0058] 2) Aging of the gel: the mixed solution a was left to stand for 48 hours, and the solution was continuously discharged slowly during the standing process, and absolute ethanol was slowly introduced, so that the modified silica wet gel was completely immersed in the absolute ethanol to form Mixture b of modified silica alcohol gel and ethanol;

[0059] 3) Drying of the gel: drying the mixed solution b under supercritical conditions to obtain a hydrophobic modified ...

preparation example 3

[0061] A highly weather-resistant tile adhesive, the preparation steps of modified silica airgel are:

[0062] 1) Sol-gel process: mix 18kg of tetraethyl orthosilicate, 10kg of octyltrimethoxysilane, 90kg of absolute ethanol, and 6kg of deionized water, stir with ultrasonic vibration at 65°C for 25min, and add 30% mass fraction ammonia water to adjust the pH value to 7.5, and continue to ultrasonically oscillate and stir for 1.5 h to form a mixed solution a of the modified silica wet gel and the solution;

[0063] 2) Aging of the gel Put the mixed solution a for 50 hours. During the standing process, the solution was slowly discharged, and the absolute ethanol was slowly introduced, so that the modified silica wet gel was completely immersed in the absolute ethanol to form a modified silica gel. Mixture b of silicone dioxide alcohol gel and ethanol;

[0064] 3) Drying of the gel: drying the mixed solution b under supercritical conditions to obtain a hydrophobic modified silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com