Production method of tripentaerythritol with purity of more than 90%

A technology for the production of tripentaerythritol, which is applied in ether separation/purification, ether preparation, organic chemistry, etc., can solve the problems of difficult separation, low purity, and low yield of tripentaerythritol, so as to improve the primary yield and increase production Efficiency and product quality have no effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

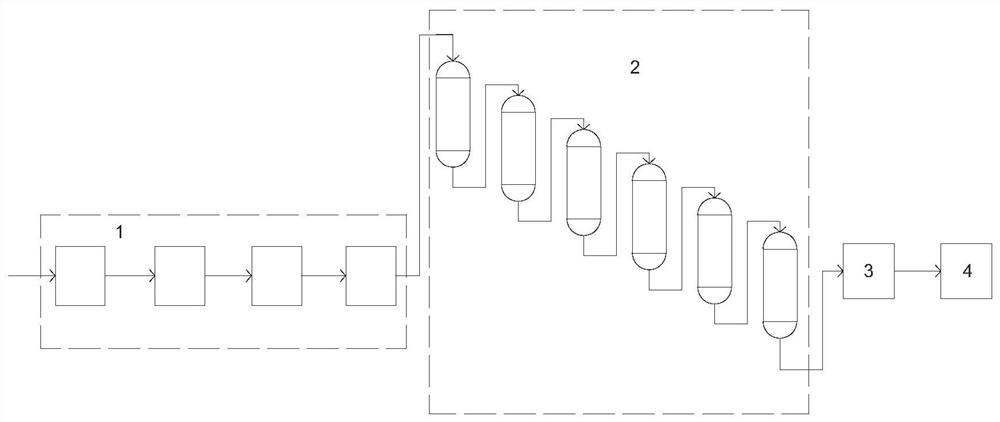

[0022] Example 1: as figure 1 Shown, the crude product of tripentaerythritol continuous production system, it comprises four-tank reactor 1, continuous overflow crystallization device 2, filter 3 and filter cake buffer tank 4;

[0023] Four-tank series reactor 1 includes 1# condensation reactor, 2# condensation reactor, 3# condensation reactor and 4# condensation reactor, 1# condensation reactor and 2# condensation reactor are connected by pump; 2# condensation reactor Connect with 3# condensation reaction kettle by pump; 3# condensation reaction kettle and 4# condensation reaction kettle are connected by pump;

[0024] The continuous overflow crystallizing device 2 includes six crystallizing tanks connected in series, and the position of the previous crystallizing tank is higher than that of the next crystallizing tank. In this embodiment, the installation height difference of two adjacent crystallizing tanks is 50mm. The bottom outlet of the previous crystallizing tank is c...

Embodiment 2

[0026] Embodiment 2: the production method of tripentaerythritol with purity greater than 90%, it comprises the steps:

[0027] (1) Condensation reaction to prepare condensate: as figure 1 As shown, the four-pot series reactor 1 includes a 1# condensation reaction kettle, a 2# condensation reaction kettle, a 3# condensation reaction kettle and a 4# condensation reaction kettle, and the 1# condensation reaction kettle and the 2# condensation reaction kettle are connected by a pump; 2# The condensation reaction kettle and the 3# condensation reaction kettle are connected by a pump; the 3# condensation reaction kettle and the 4# condensation reaction kettle are connected by a pump. The molar ratio of formaldehyde, acetaldehyde and liquid caustic soda is 4.1-4.9:1:1.10-1.15 and put into 1# condensation reaction kettle, wherein the mass percent concentration of formaldehyde is 15%, the mass percent concentration of acetaldehyde is 25%, and the liquid The mass percentage concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com